Now that the civil engineering is complete, the cavern for the ATLAS detector at the LHC is ready for the complex business of installing the detector, as Robert Eisenstein explains.

In April 2007, one of the largest and most complex sets of scientific instruments ever constructed – the Large Hadron Collider (LHC) and its four companion detectors – is scheduled to begin its odyssey into the uncharted waters beyond the Standard Model of particle physics. The discoveries that are likely to be made there could fundamentally change our ideas about the basic constituents of matter, and therefore our concepts of the universe itself. It is this hope that has led the 20 member states of CERN, and a number of non-member state partners as well, to promote, develop, fund and build the LHC project. In addition, several thousand physicists have bet a substantial part of their careers on the success of the LHC.

From the initial concept in the mid-1980s, the LHC project has followed a winding road on its way to completion. Challenging the frontiers of technology on many fronts simultaneously is one of its biggest risks, as in many cases the appropriate solutions to technological issues – and their costs – had to be presumed well in advance of construction. The sheer size of the LHC itself, and of the two biggest detectors ATLAS and CMS, presented major challenges in civil and mechanical engineering, as physicists and engineers struggled to optimize the physics return for minimal size and cost. The project has also written new standards for international co-operation in science, as much of the apparatus is being constructed in laboratories all over the world and then brought to CERN for final assembly. These tasks have often been accomplished by international teams of technicians working across a variety of languages and cultures, but with a common goal in mind. For the most part this process has worked very well indeed, and at the time of writing the ATLAS collaboration consists of about 1700 physicists from more than 150 institutions.

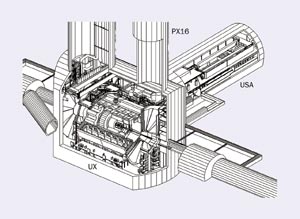

A significant milestone was achieved on 4 June this year when the ATLAS detector cavern, UX15, and its associated buildings and underground structures at Point 1 on the LHC ring were accepted on schedule by CERN. The day was marked by a ceremony and commemorated by many dignitaries, including Pascal Couchepin, president of the Swiss Confederation, Carlo Lamprecht, Geneva state councillor, and CERN’s director-general Luciano Maiani. With this dedication, Winston Churchill’s famous phrase from a very different era comes to mind: “We have reached the end of the beginning” of ATLAS construction. Now the difficult work of assembling ATLAS underground can start.

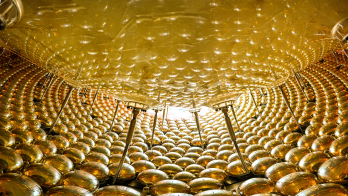

The words “ATLAS installation” do not nearly do justice to the magnitude of this task. During a three and a half year period from April 2003 until December 2006, more than 7000 tonnes of large, delicate apparatus will be lowered into UX15, itself located 100 m underground. The many heavy objects must be aligned with very high precision so ATLAS is able to measure particle trajectories and energies with the accuracy required to extract the fundamental secrets of nature for which it is searching. Then, from the end of December 2006 until the beam is turned on in April 2007, the early commissioning of ATLAS will occur. When ATLAS is “ready for physics”, more than 100 million sensors will be alive inside the detector. It will produce petabytes of information per year when the LHC achieves full luminosity.

ATLAS will be the largest-volume detector ever constructed for high-energy physics at 46 m long, 25 m wide and 25 m high. However, at 7000 metric tonnes it is not the heaviest detector – that honour belongs to another of the LHC detectors, CMS, which weighs 12,500 metric tonnes. The relatively light weight of ATLAS is due to the design of its superconducting magnet system, which is based on air-core barrel and endcap toroid magnets and a central solenoid that will provide a field of 2 Tesla.

Not surprisingly, costs have played a major role in determining the final design and configuration of ATLAS. In particular, cost considerations limited the size both of the ATLAS experimental hall and its access shafts, and the detector was in turn designed to make optimal use of the available space – but with sufficient modularity that individual pieces would fit within access-shaft allowances. It was determined early on that two smaller access shafts were significantly cheaper than one shaft large enough to accommodate the entire detector or a major sub-assembly. In another cost-cutting move, the dimensions of the barrel toroid coils were minimized, as were the access shafts. However, the final design for the ATLAS cavern UX15 is not much different in size from the original concept: its dimensions are an enormous 53 m long, 30 m wide and 35 m high.

Given the large volume of UX15, there were important geologic considerations to take into account in determining its location on the LHC ring. Of the available sites, Point 7 was best in terms of stability and absence of water leakage, but ruled out due to the proximity of civil constructions in neighbouring Ferney-Voltaire. Of the remaining locations, Point 5 was ruled out because the rock formations there are not robust enough to support a cavern the size of UX15. In the end, Point 1 was chosen as the least expensive alternative – other sites would have required costly remediation. But there are issues even at Point 1; since ATLAS is light compared with the rock formerly in place, there is expected to be significant upward floor movement that must be estimated and taken into account in the ATLAS installation.

The ATLAS civil construction was also interesting from another point of view – the desire to execute as much of it as possible without interfering with the operations and infrastructure of LEP. To do this the UX15 cavern was built “from the top down” using a novel suspended roof that was later “lowered” into place when the cavern walls were completed. This ingenious solution to a complex problem is typical of the outstanding creativity of CERN’s Civil Engineering Group and its consultants in their approach to the construction of the LHC project.

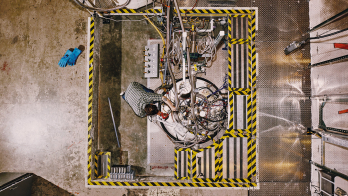

Another cost-saving measure was the decision to minimize strictly the construction of new buildings for the pre-assembly of major components of ATLAS above ground. Because there is no staging area, some of the large subcomponents of ATLAS – for example the barrel toroid magnet – will be completely assembled for the first time only when underground in UX15. As much pre-assembly and testing as possible will be done on the surface, but there is a limit to how much can be done. And since there is no large staging space available at Point 1, detector components, having been assembled at various locations at CERN, must be transported to Point 1 for installation. As some of these items are enormous, this is a task requiring great care. All this implies the need for a very carefully sequenced and choreographed installation procedure. For all these reasons ATLAS is sometimes referred to as a modern day “ship in a bottle”.

These considerations also determine the installation strategy to be used. The installation process is organized into six sequential phases: (1) surface and underground infrastructure, (2) barrel toroid and barrel calorimeters, (3) barrel muon chambers and endcap calorimeters, (4) inner detectors and muon “big wheels”, (5) endcap toroids and muon “small wheels” and (6) vacuum pipe, shielding and closing. Of course, considerable testing will be done en route to ensure that components are working properly and once installation is complete it will be extremely difficult, almost impossible, to work backward to remove any of the large sub-detectors for major servicing. The barrel toroid is perhaps the most dramatic case in point.

Safety is a paramount concern for everyone in ATLAS, and all the installation activities have been designed with this in mind. Elaborate but practical procedures control the access of people into Point 1, especially the underground areas. Entry of tools and materials will also be carefully monitored so that, for example, when the large magnets are finally energized there will be no metal flying about. The future presence of large amounts of liquid argon in UX15 is also an important safety concern.

The ATLAS Technical Coordination Team has organized the installation strategy using modern project-management ideas and tools. Resource needs (people, cash, special tools, cranes, etc) and schedules are evaluated and monitored using resource-loaded scheduling based on work package, deliverable and milestone concepts. The installation schedule is very much viewed as a living document. It currently contains over 1800 individually scheduled tasks.

The installation of each of these enormous detectors is a rewarding but formidable challenge. Stay tuned to CERN Courier for the latest updates!

Further reading

More information about the ATLAS installation process is publicly available at the ATLAS website (www.cern.ch/atlas), in the technical coordination section.