The European Synchrotron Radiation Facility provides a unique environment for industry users to translate their materials R&D into high-impact technologies. Joe McEntee reports.

The European Synchrotron Radiation Facility (ESRF) in Grenoble, France, is among an elite class of fourth-generation advanced light sources – an X-ray “super-microscope” that enables researchers to illuminate the structure and behaviour of matter at the atomic and molecular level. As such, the ESRF’s synchrotron beamlines offer leading-edge materials characterisation capabilities for applied scientists and engineers to address research challenges at all stage of the innovation life cycle – from product development and manufacturing through operational studies related to ageing, wear-and-tear, restoration and recycling. Here CERN Courier talks to Ed Mitchell, head of business development at the ESRF, about the laboratory’s evolving relationship with the industrial R&D community.

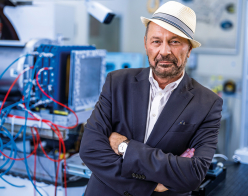

What does your role involve as head of business development?

I lead a core team of seven staff looking after the ESRF’s engagement with industry – though not the procurement of equipment and services. It’s a broad-scope remit, covering industry as a user of the facility as well as technology transfer projects and R&D collaborations with industry partners as they arise. The business development activity increasingly dovetails with the outreach efforts of leading research technology organisations – the Fraunhofer institutes in Germany, for example, and the the French Alternative Energies and Atomic Energy Commission (CEA) in France – which have extensive networks and amplify ESRF’s engagement with industry at the regional and national level.

The business development office is also responsible for identifying – and securing – strategic European Union (EU) grant opportunities. A case in point is InnovaXN, a joint PhD programme with the Institut Laue-Langevin (ILL), a neutron science facility here in Grenoble, and a ground-breaking approach to working with industry partners (see “Neutron science: simplifying access for industry users“). STREAMLINE is another of our important EU-funded projects (under Horizon 2020) and supports the recent ESRF-EBS (Extremely Brilliant Source) upgrade with new-look operation, access and automation procedures on several beamlines.

How does your team engage new industry users and partners for the ESRF?

Initiating and developing new industry contacts is a big part of what we do, though the challenge is always to talk to companies on their own terms, so that they understand the extent of the opportunities available at ESRF. A related issue is getting to the right people, especially in multinational companies with extensive R&D programmes. Sometimes we get lucky. At BASF, for example, we work closely with a senior applied research manager, someone who knows ESRF well having had links with us for many years. He’s an amazing contact, though the exception rather than the rule when it comes to industry engagement.

What about the ESRF’s outreach efforts with small and medium-sized enterprises (SMEs)?

There is EU funding available to help SMEs work with the ESRF and other advanced light sources in Europe. While this is relatively modest support, it is critical as a way of de-risking that first access for cash-strapped SMEs when they approach the big-science community. We need more of this support to scale our engagement with SMEs. Operationally, the so-called mediator companies are also incredibly important for bridging the gap to SMEs – as well as larger companies – helping them to plan, execute and deliver high-end materials characterisation services for their industrial problem-solving. It’s worth adding that the mediator companies offer value-added analysis of experimental results for research studies where we do not have the niche expertise – for example, petrochemical catalysis or the testing of consumer products (see “Prioritising the industry customer“).

So the mediator companies are one of the key elements of the ESRF’s engagement with industry?

Correct. I get a little frustrated when people imply that the mediators are simply making money off the back of the large-scale facilities. Mediator companies are another wholly valid element of the big-science ecosystem and should be celebrated as such. They add niche value, generate jobs and amplify the marketing and business development efforts of ESRF (and facilities like it) with prospective industry users. Their role is wholly positive. Entrepreneurs have seen a space, been innovative, and they’re making a living along the way. It’s a win–win.

How is the industry user base at ESRF evolving?

A substantial majority of our commercial users used to be from the pharmaceutical sector, using structural biology for drug discovery. The pharma researchers are still there, but over the last decade the industry community has become more diverse, covering more industry sectors and using a broader portfolio of synchrotron techniques. What’s more, a lot of industry users are not – and don’t aspire to be – experts in synchrotron science. Instead, they just want access to the facility for what we might consider routine measurements rather than cutting-edge research.

Those routine measurements – billed internally as “access to excellence everyday” – are only possible thanks to the specific qualities of a light source like the ESRF, with our science and technology experts working with industry to make such services more accessible and more automated. On the horizon, we can also see interest in some level of standard operating procedure for various industry use-cases, so that quality can be assured – though this will need to be considered within the context of facilities whose main mission is academic research.

What steps can you take to remain aligned with industry’s changing requirements?

Our task is to go out and listen to industry researchers and design the services they need for what they want to do – not what we think they might want. A case study in this regard is our collaboration with BASF in which ESRF and BASF scientists are co-developing a high-throughput mail-in service to support X-ray powder diffraction studies of hundreds of samples per shipment from the client’s R&D lab. This is essentially chemistry genomics, with the synchrotron beamlines providing automated and high-resolution studies of materials destined for applications in next-generation batteries, catalysts and the like. We hope to see more co-designed services being built with other companies very soon.

What about tracking the impact of industry research conducted at ESRF?

This is always tricky. More often than not, the downstream impact of confidential industry R&D conducted at ESRF remains hidden even from our view. After all, companies are unlikely to reveal how much money they saved on their manufacturing process, for example, or whether a new product was an indirect or direct result of X-ray studies at our beamlines.

In some ways, the laboratory needs perhaps just one killer quantifiable result every 10 years – think multibillion euro outcomes for industry – and the ESRF could be thought of as having justified its existence. Of course, this ignores the longer-term impact of the fundamental science conducted by academics – far and away the main user community at the ESRF. The bottom line: industry clients come back, they pay for access, so one has to assume that there is significant business impact for them.