Mediator companies are the ultimate connectors between the big-science community and industry end-users. Joe McEntee checks out the business model for specialist science services.

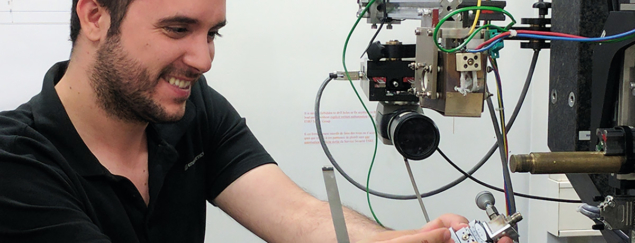

Mediator companies (also known as science-service companies) have emerged as one of the main engines of connection and collaboration between Europe’s large-scale research facilities and industry. A case in point is Finden, a UK-based outfit that helps applied scientists and engineers in a range of industry sectors – energy, industrial chemistry, catalysis and automotive, among others – to access leading-edge materials characterisation services at Europe’s synchrotron research laboratories. Finden managing director Simon Jacques talked to CERN Courier about the company’s science-as-a-service business model and plans to diversify beyond conventional X-ray analysis techniques and synchrotron science.

How is Finden helping the big-science community to grow its industry user base?

As a regular user of large-scale synchrotron facilities within Europe, we enable our industry customers to fast-track R&D projects through unique measurement capabilities tailored to their needs. Put simply, Finden helps industry clients to solve complex materials problems that they’re unable to solve on their own. It’s a winning formula: many of our customers come back to us on a serial basis, tapping the collective expertise of the Finden team and the streamlined access we provide to Europe’s synchrotron light sources.

What do you mean by streamlined access?

There are often significant logistics overheads when it comes to finding and securing beam time at a synchrotron facility – a barrier to direct industry engagement with big science. At Finden, we have the know-how, as well as an extensive network of contacts within the synchrotron community, to take care of all the associated “legwork” for our clients, matching the right beamline and scientific instruments to the industrial problem at hand. That translates into express workflows and turnaround – the key to successful delivery of high-end materials characterisation services for industrial problem-solving.

Operationally, how do new industry clients engage with Finden?

For the most part, our client base comprises established companies rather than small and medium-sized enterprises. First contact can happen in a variety of ways: an exploratory conversation with a Finden scientist at a conference, for example, or sometimes a synchrotron facility may point an industry enquiry in our direction. Once the dialogue is under way, we’ll meet with the client to understand their materials problem at a granular level – often under a non-disclosure agreement to ensure commercial confidentiality. My task as managing director is to make sure we’ve got all the right people in the room from Finden to establish the appropriate characterisation methods versus the client’s problem and specified timeline – as well as an accurate financial quotation for the plan of work.

Do all of the industry problems you tackle require synchrotron beam time?

Not all of them. We have access to a suite of powerful materials analysis techniques here on the Harwell campus (in Oxfordshire) and those lab-based tools often represent a cheaper and more efficient option for our industry clients. When we do engage with the large-scale facilities – for example, the nearby Diamond Light Source or the European Synchrotron Radiation Facility (ESRF) in Grenoble – we make all the necessary arrangements and carry out the work on behalf of the client. Sometimes our scientists will conduct materials studies at the synchrotron beamline – “eyes on the sample” so to speak – though even when working remotely the team will be conducting on-the-fly data analysis and liaising throughout with scientists and technicians in situ.

What does the business model look like for the provision of these big-science services?

It might seem counter-intuitive, but we don’t charge a premium for synchrotron beam time. That’s all billed at-cost to mitigate the chance of the customer going direct to the synchrotron. Our differentiation – and where we make our money – lies in the collective expertise of the Finden team in synchrotron science, instrumentation and techniques – not least our capabilities across experimental design, data analysis and interpretation. By extension, one of the growth opportunities we’re now pursuing is the application of machine-learning and deep-learning technologies to high-throughput data analysis. It’s early days, but we’re already securing industry contracts that tap this capability exclusively, including projects that do not require any experimental data collection on our part.

How is Finden structured right now?

Finden is really two parallel and complementary businesses under one roof. The mediator company, which provides specialist materials science capabilities to industry, rents laboratory space and equipment across the Harwell Innovation Campus on an as-needed basis, while developing a pipeline of higher-level characterisation projects that require access to Europe’s synchrotron light sources. Alongside the science-service business, we run our own dedicated research laboratory that we lease from the Science and Technology Facilities Council, a UK government funding agency. This lab is largely ring-fenced for in-house R&D and innovation initiatives under the broad themes of catalysis and machine learning – essentially longer-term bets with a view to building sustainable royalty and licensing revenues from the associated intellectual property portfolio.

What do the growth opportunities look like for Finden?

Diversification is very much part of Finden’s development roadmap. Right now, the heart of our business is materials characterisation using diffraction, spectroscopy and imaging techniques spanning conventional X-ray and synchrotron science. Conceptually, it’s a logical progression to apply those transferable capabilities to other modalities used in fundamental and applied materials research. In summary: expect to see Finden scientists tackling industry’s R&D problems at large-scale neutron and laser facilities in the not-too-distant future.