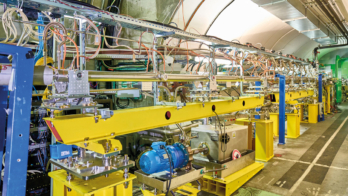

Progress on the construction of the Large Hadron Collider (LHC) at CERN has passed several important milestones in recent weeks. In mid-September the first 600 m of the cryogenic distribution line that will supply superfluid helium to the superconducting magnets passed initial testing at room and cryogenic temperatures. At the same time, the number of magnets installed in the tunnel passed the 100 mark, and several major contracts related to their construction have been successfully completed.

The tests of the cryogenic line, which were the first to be implemented at close to the eventual operating conditions in the LHC tunnel, took place in sector 7-8. This is where technical problems were discovered during the initial installation in summer 2004, so that the system had to be redesigned, repaired and reinstalled.

After several days of testing and cleaning at room temperature, the cool-down itself took 15 hours. This is a two-stage process using a 4.5 K helium refrigerator and a nitrogen pre-cooler. After the initial 10 hours of cool-down, the system reached the first temperature plateau of 80 K. Then, by the evening of 14 September, the cryogenic line had been brought down to around 5 K, about 3 K above the eventual operating temperature. The complete cold-commissioning process takes about five weeks. Once the thermal design has been validated, the magnets can then be connected to the cryogenic line.

Meanwhile, by the end of September, 102 of the LHC’s 1232 superconducting dipoles had been put in position in the tunnel. At the same time one of the most important contracts for the LHC had successfully concluded, with the supply of all 7000 km of the superconducting cable that forms the heart of the machine’s magnets. This cable has been provided by four companies in Europe – Alstom-MSA (France), EAS (Germany), Outokumpo (Finland/Italy) – Furukawa in Japan and OKAS in the US.

This was the latest in a series of contracts for the LHC that have recently come to completion. At the end of May, Belgian firm Cockerill Sambre of the Arcelor Group cast the last batch of steel sheets for the superconducting magnet yokes, which constitute around 50% of the accelerator’s weight. This was the first major contract to be concluded for the LHC; worth 60 million Swiss francs, it was signed just after CERN Council approved the LHC project in December 1996.

October saw the completion of the 60 km of vacuum pipes for the LHC beams by a single firm, DMV of Bergamo, Italy. These 16 m long pipes, made from austenitic steel, had to be continuously extruded and had to contain not a single weld in order to ensure perfect leak tightness between the vacuum inside and the superfluid helium outside. In the first week of September, the last rolls of austenitic steel for the collars of the dipole magnets arrived at CERN from NSSC (Nippon Steel) in Japan. The collars are designed to contain most of the magnetic forces created in the eight layers of superconducting coil that provide the magnetic field.

The production of the collared coils is also well on track. On 8 August Babcock Noell Nuclear (BNN) delivered their last collared coil, completing their contract for one-third of the dipole magnet coils. The contracts with the two other suppliers will also come to an end during the autumn of 2006.