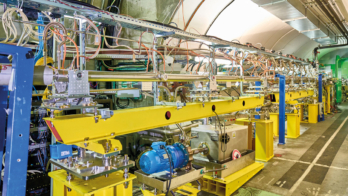

Superconductivity underpins large particle accelerators such as the LHC. It is also a key enabling technology for a future circular proton–proton collider reaching energies of 100 TeV, as is currently being explored by the Future Circular Collider (FCC) study. To address the considerable challenges of this project, a conductor development workshop was held at CERN on 5 and 6 March to create momentum for the FCC study and bring together industrial and academic partners.

The alloy niobium titanium is the most successful practical superconductor to date, and has been used in all superconducting particle accelerators and detectors. But the higher magnetic fields required for the high-luminosity LHC (11 T) and FCC (16 T) call for new materials. A potential superconducting technology suitable for accelerator magnets beyond fields of 10 T is the compound niobium tin (Nb3Sn), which is the workhorse of the 16 T magnet-development programme at CERN.

The FCC conductor programme aims to develop Nb3Sn multi-filamentary wires with a critical current-density performance of at least 1500 A/mm2 at 16 T and at a temperature of 4.2 K. This is 30 to 50% higher than the conductor for the HL-LHC, and a significant R&D effort – including fundamental research on superconductors – is needed to meet the magnet requirements of future higher-energy accelerators. The FCC magnets will also require thousands of tonnes of superconductor, calling for a wire design suitable for industrial-scale production at a considerably lower cost than current high-field conductors.

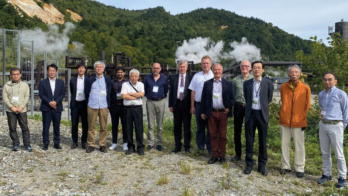

CERN is engaged in collaborative conductor development activities with a number of industrial and academic partners to achieve these challenging targets, and the initial phase of the programme will last for four years. Representatives from five research institutes and seven companies from the US, Japan, Korea, Russia, China and Europe attended the March meeting to discuss progress and opportunities. Firms already producing Nb3Sn superconducting wire for the FCC programme are Kiswire Advanced Technology (KAT); the TVEL Fuel Company working with the Bochvar Institute (JSC VNIINM); and, from Japan, Furukawa Electric and Japan Superconductor Technology (JASTEC), both coordinated by the KEK laboratory. Columbus Superconductor SpA is participating in the programme for other superconducting materials, while two additional companies – Luvata and Western Superconducting Technologies (WST) – expressed their interest in the CERN conductor programme and attended the workshop.

The early involvement of industry is crucial and the event provided an environment in which industrial partners were free to discuss their proposed technical solutions openly. In the past, most companies produced a bronze-route Nb3Sn superconductor, which has no potential to reach the target for FCC. Thanks to their commitment to the programme, and with CERN’s support, companies are now investing in a transition to internal tin processes. Innovative approaches for characterising superconducting wires are also coming out of academia. Developments include the correlation of microstructures, compositional variations and superconducting properties at TU Wien, research into promising internal-oxidation routes at the University of Geneva, phase transformation studies at TU Bergakademie Freiberg and research of novel superconductors for high-fields at SPIN in Genova.

The FCC initiative is of key importance for future high-energy accelerators. Participants agreed that this could result in a new class of high-performance Nb3Sn material suitable not only for accelerator magnets, but also for other large-scale applications such as high-field NMR and laboratory solenoids.

• Panos Charitos, CERN.