The collaboration for the Compact Muon Solenoid (CMS) experiment at CERN’s future LHC collider will base its tracker entirely on silicon sensor technology using fine feature size electronics (subject to the approval of an addendum to the experiment’s Tracking Technical Design Report by the LHC committee).

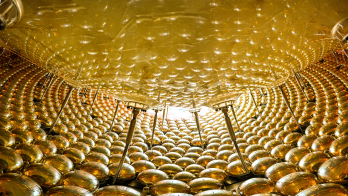

The tracker is the innermost module of the huge detector, picking up signals from particles that are produced by the colliding LHC beams. Building such a 6 m long and 2.5 m diameter high-technology precision instrument for the demands of LHC physics is a major challenge.

The decision to go all-silicon follows unexpectedly rapid recent advances in read-out for microstrip detectors, in the fabrication of sensors on 6 inch diameter silicon wafers, and automated assembly techniques for an all-silicon detector. It is a significant departure from the CMS baseline tracker proposal, which foresaw a central region of silicon devices surrounded by microstrip gas chambers (MSGCs).

The decision was a difficult one for CMS, coming soon after the successful demonstration, in beam tests at the Paul Scherrer Institute in Switzerland, that MSGCs would be equal to the task of particle tracking at the LHC.

In the mid-1990s MSGCs seemed to offer an economical alternative to silicon. In early implementations, however, their performance was found to deteriorate significantly with increased exposure to ionizing particles. This would have ruled them out for prolonged use at the LHC, where unprecedented particle fluxes are expected.

Nevertheless, solutions to these teething problems seemed to be available and CMS chose MSGCs as their baseline proposal, on the condition that certain milestones were reached. These were successfully achieved, but silicon-related technology was advancing in parallel, reducing the cost advantage that MSGCs offered.

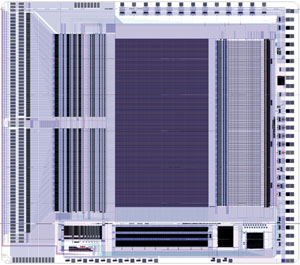

A decisive factor in reducing the tracker’s price tag, by almost 6.5 million Swiss francs, was the development by CMS of a CMOS read-out chip using low-cost technology, originally aimed at increasing the compactness of computer chips. With a feature size of 0.25 mm compared with the 1 mm of conventional CMOS chips, the new APV25 chip is certainly compact. What the computer industry did not plan for, however, is that it is also extremely radiation-hard, with lower noise and power consumption than a conventional CMOS chip. This combination of features is ideal for CMS’s needs. It also provided important input to the choice of an all-silicon detector.

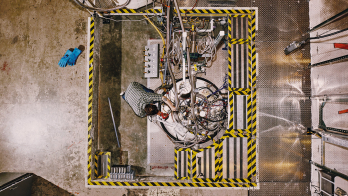

The other decisive factor is that silicon detectors are already widely available from industry in large quantities, and their price has been falling. Coupled with new automated assembly techniques developed at CERN, silicon therefore gave CMS the greatest chance of completing its full tracker on time and budget for LHC start-up.

“We believe that a new era is being entered, of assembling an enormous detector using automated assembly techniques,” said Geoff Hall of the CMS collaboration, “which is only possible today with silicon.”