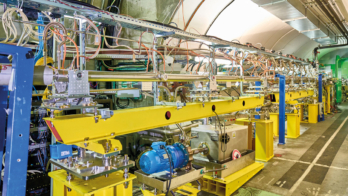

Spearheading the construction effort for CERN’s LHC collider is the groundwork for the 1232 superconducting dipole magnets, to be cooled by superfluid helium at 1.9K. Material procurement and tooling is advancing hand in hand with the final research and development work for the production design.

One of thevfirst major LHC procurement contracts was for the superconducting materials niobium-titanium bars andvniobium sheet worth $45 million – with Wah-Chang in the US and using US money. This was followed by contracts for the actual cable manufacture. A total of 13 680 kilometres of cable will be needed, longer than the diameter of the Earth. As well as being for the dipoles, this material will also be used for the 520 focusing quadrupoles and several other magnets.

Involved in this manufacture are Alsthom (France), Vacuumschmelze (Germany), Europa Metalli (Italy), Furukawa (Japan) and IGC (USA), reflecting the worldwide involvement in the LHC.

Testing and quality assurance of the superconducting strands, and subsequently the full cable, is absolutely vital. A new test facility at CERN, equipped with its own helium refrigerator, will come into operation soon. This facility will be used for quality control of the strands during production, whereas most of the final cable will be tested in a similar facility at Brookhaven as part of the CERNUS collaboration.

For the magnets themselves, tests on 1 metre dipole models underlined the wisdom of reverting to the original 6-block coil design after a flirtation with a 5-block configuration.

During 1998 two more 10 metre collared coils were delivered by industry and assembled at CERN into complete magnets, and the first 15 metre prototype dipole, built by industry under an agreement between CERN and the Italian INFN, was put through its paces. While the nominal field for LHC magnets to handle 7 TeV beams is 8.34T, 9T is seen as the ultimate goal. While the former figure is usually a cinch, the latter is not, underlining the need for careful quality control at all stages in the manufacture and assembly, and the importance of the collaring procedure to anchor all components securely under immense magnetic forces and when cooled to 2 K.

Orders for six prototype collared coils with the series manufacture design have been issued, and the first has even arrived. These will be assembled into cryomagnets at CERN, as industry is not yet equipped with the necessary 15 metre hydraulic presses for the welding of the cold mass.

Prototype high-temperature superconducting current leads have been ordered and tested. Other cryogenic-related equipment reflects further the world involvement in the LHC. Power supplies for quench heaters are being developed by a collaboration working through the Indian Centre of Advanced Technology, Indore, while equipment to handle the extraction of the stored superconducting energy in the event of a quench is being designed and constructed by Russian industry and by IHEP, Serpukhov.

Also being supplied from Russia, in this case the Budker Institute, Novosibirsk, are 360 warm dipoles and 180 quadrupoles for the two 2.5 km transfer lines feeding protons from the SPS to the LHC. The first magnets have arrived.

With the technical specification of the dipole cold masses complete, almost the last act of 1998 at CERN was to issue a call for tenders for the first phase of LHC dipole procurement.