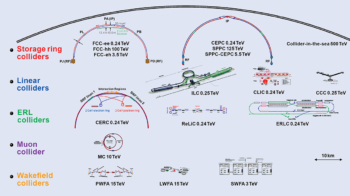

Niobium cavities vital for LHC upgrade, future colliders and X-rays.

Image credit: Fermilab.

Behind the size, complexity and physics goals of particle accelerators such as the LHC lies a simple physics principle worked out by Maxwell more than 150 years ago: when a charged particle passes through an electric field it experiences an acceleration proportional to the electric-field strength divided by its mass. While the magnets of a circular accelerator keep the beams on track, it is this principle that shunts them to the high energies needed for particle-physics research. The first accelerators relied on electrostatic fields produced between high-voltage anodes and cathodes, but by the mid-1920s it was clear that radio technology was needed to reach the highest possible energies.

To transfer energy to a beam of charged particles, a space must be created where the beam can move along an electric field produced by high-power radio waves; the higher the field, the larger the energy gain per metre (accelerating gradient). An accelerating space, usually called a radio-frequency (RF) cavity, is a container crossed by the beam in which is stored a rotational electric field that, when the bunch of particles is passing through, is found to be properly orientated in the desired direction. Whatever geometry the cavity has, the power dissipated by the Joule effect is proportional to its surface resistance and to the square of the field inside it.

For the past 30 years, superconducting radio-frequency (SRF) cavities have been in routine operation in a variety of settings, from pushing frontier accelerators for particle physics to applications in nuclear physics and materials science. They were instrumental in pushing CERN’s LEP collider to new energy regimes and in driving the newly inaugurated European X-ray Free Electron Laser. Advanced SRF “crab cavities” are now under development for the high-luminosity upgrade of the LHC.

From Stanford to LEP

It was unclear at first whether superconductivity had much value for RF technology. When a superconductor is exposed to a time-varying electromagnetic field, the electrons that are not coupled as Cooper pairs lead to energy dissipation in the shallow layer of the superconductor surface in which the electric and magnetic fields are dancing together to sustain the rotational electric field that transfers the energy to the beam. But it was soon realised that in the practical frequency range of RF accelerators, from a few hundred MHz to a few GHz, the use of SRF cavities would produce in any case a significant breakthrough due to the increase in the conversion efficiency from plug- to beam-power, cryogenics included. It was simply a question of developing the technology, and this required investment and big projects.

The High-Energy Physics Lab at Stanford University in the US was a pioneer in applying SRF to accelerators, demonstrating the first acceleration of electrons with a lead-plated single-cell resonator in 1965. Also in Europe, in the late 1960s, SRF was considered for the design of proton and ion linacs at KFK in Karlsruhe. To be superior to the competing technology of normal-conducting RF, a moderate field of a few MV/m was necessary. By the early 1970s SRF had been introduced in the design of particle accelerators, but results were still modest and a number of limiting factors needed to be understood.

Image credits: CERN.

The first successful test of a complete SRF cavity at high gradient and with beam was performed at Cornell’s CESR facility at the end of 1984, involving a pair of 1.5 GHz, five-cell bulk niobium cavities with a gradient of 4.5 MV/m. This cavity design was then used as the basis for the CEBAF facility at Jefferson Lab. Cornell’s success also triggered activities at CERN, where some visionary people were already looking at SRF as a way to double the energy of the Large Electron–Positron (LEP) collider under construction in what is now the LHC tunnel. LEP’s nominal centre-of-mass energy of 90 GeV was the minimum required to produce the recently discovered Z boson, but almost double this energy was needed to test the Standard Model further: specifically, to produce pairs of W bosons.

The baseline accelerating system of LEP was already a jewel that had demanded all the knowledge and ingenuity available globally at that time. Furthermore, doubling its energy meant that researchers had to battle additional losses due to synchrotron radiation, which scales as the fourth power of the electron and positron energies. The dream was to develop an accelerating system that made use of the very low losses promised by superconductivity to deliver a factor 16 or so more energy per turn to the LEP beam, occupying more or less the same space as the machine’s original copper cavities.

Developing the SRF system for “LEP II” was a great challenge and success for the accelerator community. Owing to the relatively low resonant frequency – 352 MHz – of LEP’s underlying design, the superconducting cavities developed ended up being more than four times bigger than the ones successfully tested at Cornell. Since 1979, a small group at CERN had been developing the SRF technology, including all the cavity’s ancillaries necessary for its eventual working, but the best niobium superconducting material produced at that time was not sufficiently performant at such scales, and the first tests cast doubt as to whether the LEP-II dream could be realised. In 1989, a pilot project of 20 niobium cavities started to evaluate the feasibility of LEP-II SC cavities. In the meantime, the niobium-copper (Nb/Cu) technology developed at CERN by Cris Benvenuti became mature enough to justify the decision to base the LEP-II programme on Nb/Cu SRF cavities. Their inherent advantages, including the possibility to replace the Nb coating by a better one in the future, were decisive in making this choice. Soon the CERN technology was transferred to industry and more than 300 2.4 m-long SRF cavities were successfully produced by three companies in France, Germany and Italy. By 2 November 2000, when LEP II was switched off to allow the LHC to be constructed, the collider’s energy had topped 209 GeV. More than 17 million Z bosons were produced, and a large number of pairs of W bosons, allowing extremely precise tests of the Standard Model of particle physics. LEP missed the Higgs discovery, and we now know that a centre-of-mass energy just a few tens of GeV higher would have been sufficient to produce the fundamental particle. But this was never a realistic prospect: the machine was already pushed to its limit and any further energy increase would have eventually produced an irreparable failure.

While CERN and LEP-II were creating a valuable technology for very large SRF cavities, Jefferson Lab in the US was set to build the CEBAF accelerator. This required installing a large and complete infrastructure to develop the SRF technology based on bulk niobium, going beyond the needs of CEBAF – possibly unavoidable for the success of such a challenging project that was the first of its kind. The decision resulted in the large-scale production of 300 small cavities based on Cornell’s design, but with a marginal contribution from industry mainly limited to the mechanical fabrication of the cavities with no surface treatment. The experience of CEBAF was nevertheless important for the evolution of SRF technology and some of the techniques applied became standard. Among them was the development of electron-beam welding parameters for niobium, the use of clean-room assembly and ultrapure-water rinsing, and some optimisation of the surface treatment of the active internal surface of the SRF cavities. CEBAF was also the first SRF accelerator to be cooled by superfluid helium, operating at a temperature of 2 K. The large cryogenic plant designed and built to cool CEBAF has itself been a crucial step in the development of superconducting technology, not just SRF but also for accelerator magnets such as those used in the LHC.

Concluding this important chapter in SRF development in the mid- to late-1980s are two other major high-energy-physics projects: TRISTAN at KEK in Japan and HERA at DESY in Germany. Each produced, through a big national company, state-of-the-art SRF technology involving moderate cavities, typically 500 MHz, of four to five cells, in bulk niobium. The new technologies reached an accelerating electric field of about 5 MV/m, while substantially improving the performances of HERA and TRISTAN.

Linear adventure

All of these large accelerators were still to be completed when, in July 1990, a meeting was held at Cornell, organised by Ugo Amaldi and Hasan Padamsee, to discuss the possibility of developing SRF technology for a future TeV-scale linear collider (thereby avoiding the synchrotron-radiation losses suffered by circular colliders). The proposed name of this object was TESLA and, after three days battling with various figures, we were convinced that such technology was possible. Amaldi returned to CERN to gather support and, one and half years later, over a dinner in a restaurant in Blankenese in Hamburg hosted by Bjørn Wiik, a dozen or so colleagues, including Maury Tigner, Helen Edwards and Ernst Habel, proposed that DESY should host an international collaboration with the task of developing TESLA.

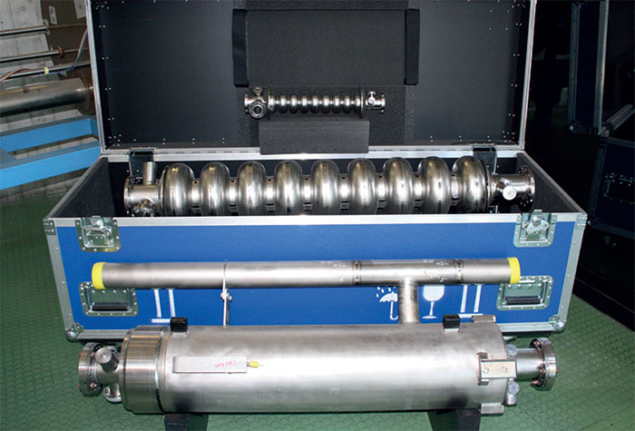

The great success of TESLA in opening a new era of SRF had a number of concomitant causes, in addition to the great enthusiasm, friendship and ingenuity of those involved. We had the recent experiences from LEP-II and CEBAF, for instance, plus cryogenic experience from DESY and Fermilab. The memorandum of understanding helped to inspire a pure scientific research style, with no secrets among the partner institutes and constructive competition to produce the best technology possible. Once the cavity frequency (1.3 GHz) and the number of cells per cavity (nine) had been agreed, we designed the TESLA Test Facility. This central infrastructure at DESY was to treat the active/internal surface of cavities, control and verify each step of the material and cavity production, and finally test the cavities and ancillaries in all conditions, naked and fully dressed, with and without beam. In contrast to the construction of LEP-II and CEBAF, the fabrication of the cavities themselves was handed over to industry. This turned out to be a crucial decision, leading researchers into collaboration with competing firms and taking advantage of their expertise and ingenuity. The test with beam brought about a prototype of the TESLA linac that, with the addition of some undulators, was renamed FLASH in 2003 – the harbinger of the European XFEL.

In 1996, we had the first eight-cavity cryomodule in operation with beam and a stable production of cavities performing a few times better than envisaged. The challenging objective of TESLA’s mission was now very close in terms of both accelerating gradient and cost. The factor 20 improvement required to compete for the linear-collider prize was almost there. By 2000, a novel chemical process called electropolishing, developed by Kenji Saito of KEK, and a final cavity baking at moderate temperature introduced at CEA-Saclay by Bernard Visentin, took TESLA over the finish line. The success of TESLA technology was not just due to the cavity performance, but also the parallel development of power couplers, frequency tuners and other ancillaries.

The ability to accelerate very-high-power beams of protons to produce a huge flux of neutrons had major implications for neutron spallation sources like SNS in the US and the ESS under construction in Sweden, for nuclear-waste transmutation, and for accelerators for heavy ions. It took some time, but most new accelerators are in some way based on TESLA technology.

Continuing application

In 2004 the International Technology Recommendation Panel gave momentum to the newly named International Linear Collider (ILC). But it was clear that the eventual construction would not begin for at least a decade, in any case after a better definition of the physics case expected from the LHC. In the meantime, the European X-ray Free Electron Laser (XFEL), which began construction in Hamburg in 2009 and was completed this year (CERN Courier July/August 2017 p25), was the best opportunity for the TESLA collaboration to continue with the development of SRF technology. The realisation with industry, on budget and on time, of the advanced-SRF European XFEL has possibly been the most important recent milestone toward new frontiers for high-energy physics. Nevertheless, its 800 nine-cell cavities represent only 5% of the total number required by the ILC.

While SRF has made fantastic progress towards a linear collider and achieved a degree of maturity with the European XFEL, future circular colliders present additional R&D challenges that are similar and also complementary to the quest for very large accelerating gradient. The total power to be transferred to the beams in case of a future electron-positron collider, for example, is 100 MW continuously. This challenges the present concepts of high-power couplers, requires new ideas to minimize dynamic cryogenic losses, and has triggered R&D on new materials and fabrication techniques.

Concluding this historical summary, SRF has now reached a high level of technological development, handled by advanced industry, similar to that reached for magnets 15 years ago. As in the case of superconducting magnets, physics – and high-energy physics in particular – has been the most significant driving force. As with accelerator magnets such as those in the Tevatron, HERA and the LHC, projects such as LEP-II, CEBAF and TESLA/ILC have played a crucial role to transform, through technology transfer and industrialisation, an exotic phenomenon into a promising and useful technology. So far, the existing technology is sufficient for today’s applications. But basic research always seeks the next paradigm shift, and R&D taking place in laboratories such as CERN will allow us to go beyond present limitations.

Three state-of-the-art SRF projects for the High Luminosity LHC and beyond

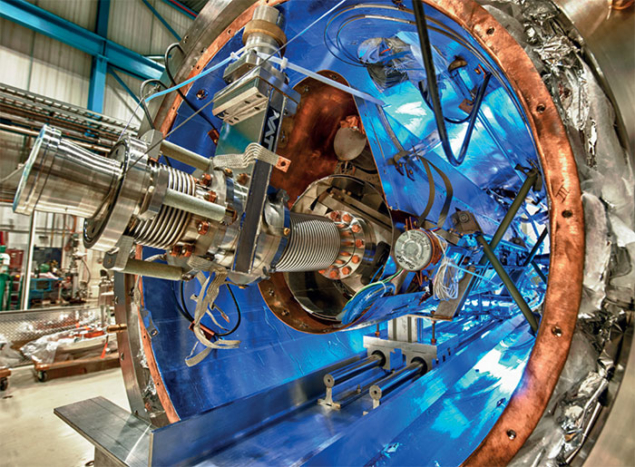

• Exotic cavity geometries and ancillaries to perform specific gymnastics on the beam to significantly improve the collider luminosity. For example, “crab cavities” (pictured right) are under development at CERN for the high-luminosity LHC with the support of a highly expert collaboration. Starting from existing advanced SRF cavities, the group developed two complementary cavity packages that will tilt the two LHC beams just before they collide, to maximise their overlap and then substantially increase the collision rate. After the collision the beam is returned to its original orbit and the challenge is to do all of this without perturbing the beam. So far, two (out a total of 16) superconducting crab cavities have been manufactured at CERN and RF tests at 2 K have been performed in a superfluid helium bath. The first cavity tests earlier this year demonstrated a maximum transverse kick voltage exceeding 5 MV, corresponding to extremely high electric and magnetic fields on the cavity surfaces. By the end of 2017, the two crab cavities will have been inserted into a specially designed cryomodule that will be installed in the Super Proton Synchrotron to undergo validation tests with proton beams.

• Doping the very thin layer on the cavity inner surface that sustains the electromagnetic accelerating field to reduce the power dissipation at cryogenic temperatures, using a minor quantity of gas such as nitrogen. This R&D project, led by Anna Grassellino at Fermilab, is giving very promising results and is being experimentally applied on the LCLS-II X-ray free-electron laser (XFEL) under construction at SLAC. Once the technology is stabilised, the benefit in terms of investment and operation costs will hopefully be very important for all large accelerators requiring a continuous beam, such as new circular colliders, continuous-wavelength XFELs approved or under construction, and accelerator-driven systems for new nuclear-power technology.

• Niobium-tin (Nb3Sn) coating of SRF cavities. This technology has been pursued in a few laboratories for some time, with moderate success. But recent results from Cornell and Fermilab on real single-cell elliptical cavities are close to those obtained with pure niobium, and this could be the starting point for possible application of Nb3Sn coatings in large accelerators. The coating technique, once properly developed, could have significant advantages, mainly because of the higher critical temperature and critical magnetic field of Nb3Sn with respect to those of pure Nb.