The benefits of carbon-dioxide cooling for silicon detectors.

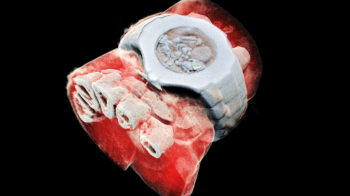

Image credit: NASA.

Cooling with carbon dioxide has benefits that are making it the preferred choice for the latest generation of silicon detectors.

The demand for efficient cooling systems that employ relatively small amounts of material – i.e. “low mass” systems – is becoming increasingly important for the new silicon detectors that are being used in high-energy physics. One solution that is gaining popularity is to use evaporative cooling with carbon dioxide (CO2). Currently, two detectors are cooled this way: the Vertex Locator (VELO) in the LHCb detector; and the silicon detector of the orbiting AMS-02 space experiment on board the International Space Station. The CO2 cooling system for VELO has been working since 2008 and the one on AMS has operated in space since May 2011. Both systems have so far functioned without any major issues and both are stable at their design cooling temperature, –30°C for the VELO and 0°C for AMS.

The benefit of using CO2 cooling is that it becomes possible to use much smaller cooling pipes compared with other methods used to cool particle detectors. The secret of CO2 is based on the fact that evaporation takes place at much higher pressures than other two-phase refrigerants. In general, the volume of vapour created stays low while it remains compressed, which means that it flows more easily through small channels. The evaporation temperature of high-pressure CO2 in small cooling lines is also more stable because the pressure drop has a limited effect on the boiling pressure. Savings in the mass of the cooling hardware in the detector when using CO2 can be as high as an order of magnitude compared with other methods used to date.

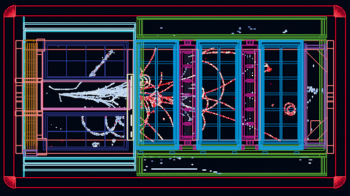

The thermal performance of a cooling tube is based on two components: the temperature gradient along the tube caused by the changing boiling pressure, and the temperature gradient from the wall of the tube into the fluid – which depends on the heat-transfer coefficient. It is difficult to compare different fluids with each other because the combination of these two performance indicators leads to different results for different tube geometries, heat-load densities and cooling temperatures. To show the benefits of CO2, a specific case is plotted in figure 2 for a 1-m-long tube with a heat load of 500 W at –20°C. As efficiency in terms of the amount of matter in the cooling system is the driving factor in particle detectors, the cooling efficiency is plotted in terms of thermal conduction per cooling-tube volume. The benefit of using CO2 is clear, especially in tubes with a small diameter. The general tendency for high-pressure fluids to have the best performances is also clear – only ammonia in this example seems to deviate from this trend.

Apart from its outstanding thermal performance, CO2 is also a practical fluid. It is neither flammable nor toxic, although it will asphyxiate when released in larger quantities. In general, the small systems used in laboratories have smaller volumes than a standard fire extinguisher and are not dangerous if the CO2 contents were to leak out. The larger systems used in detectors, however, must be designed with proper safety precautions. Some additional benefits of using CO2 are the low utilization costs, the fact that it is a natural gas and, importantly, compatibility with sensitive instruments – contact with CO2 is in general not damaging to electronics or other equipment. CO2 does not exist as a liquid in ambient conditions and when released it is vented as the solid–gas mixture known as dry ice. CO2 evaporates from its liquid phase between –56°C and +31°C and a practical range of application is from –45°C to +25°C.

For LHCb and AMS, a special CO2-cooling method has been developed that is different from ordinary two-phase cooling systems. The best performance of the evaporative CO2 method is achieved with an overflow of liquid, rather than evaporating the last drop. A liquid-pumped system with external cooling is preferable to a compressor-driven vapour system of the kind used in refrigerators. A big advantage is that a liquid-pumped CO2 system is relatively simple, which is useful when integrating it into a complex detector. The CO2 condensing can be done externally using a standard industrial cooler.

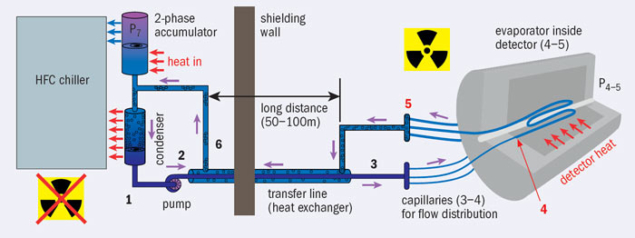

The method that has been developed for cooling detectors is called 2PACL, for 2-Phase Accumulator Controlled Loop. Accumulator control being a proven method in existing two-phase cooling systems for satellites, this method was initially developed for AMS by Nikhef in an international collaboration led by the Netherlands National Aerospace Laboratory, NLR. The novelty is precise pressure regulation with a vessel containing a two-phase CO2 mixture. The benefit of using this system with detectors is that the cooling plant containing all of the active components can be set up some distance away. The cooling plant can be designed to be remote from the inaccessible detector, leaving only tubing of small diameter inside or near the detector.

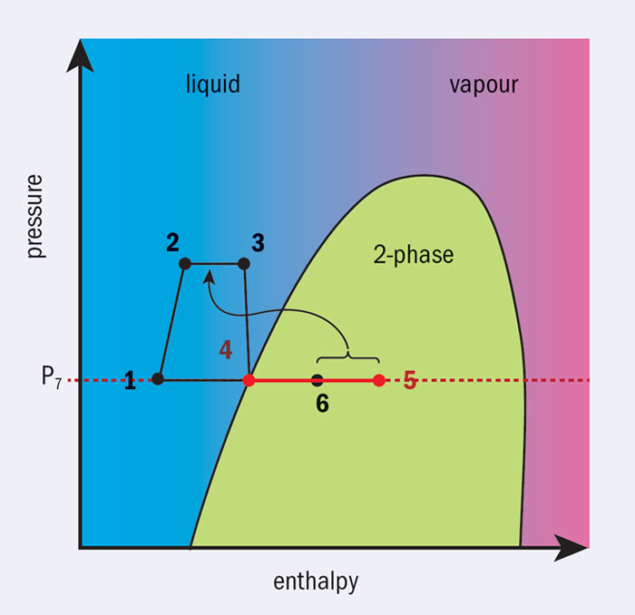

Figure 3 shows the thermodynamic cycle for the 2PACL system in a pressure–enthalpy diagram – a useful representation of the cycle in evaporative-cooling systems. Figure 4 shows the 2PACL principle used in detectors, with the node numbers corresponding to those used in figure 3. For AMS, the external cooler was replaced by cold radiator panels mounted on the outside of the experiment (see figure 1).

The 2PACL concept was also successfully applied by Nikhef for cooling the LHCb’s VELO with CO2 and it has become the baseline concept for future detectors that are under development. The pixel detectors for ATLAS and CMS phase-1 upgrades are being designed to be cooled by the 2PACL CO2 system and the same technology is also under consideration for the silicon detectors for the full phase-2 upgrades for ATLAS and CMS. Elsewhere, CO2 cooling is under development for the Belle-2 detector at KEK and the IL-TPC detector for a future linear collider. Industrial hi-tech applications are also showing interest in the technique as an alternative cooling method.

Image credit: Kamil Cichy.

Currently, CERN and Nikhef are developing small, laboratory CO2 coolers for multipurpose use (figure 5). The units, called TRACI, for Transportable Refrigeration Apparatus for CO2 Investigation, are relatively low cost and optimized for a wide operating range and user-friendly operation. Five prototypes have been manufactured and the hope is that results from these units will lead to a design that can be outsourced for manufacture by external companies. In this way, the many research laboratories investigating CO2 for their future detectors could be supplied with test equipment.