New muon end-cap wheels currently being installed in the ATLAS detector will provide precision tracking and triggering at high rates for Run 3 and beyond.

The Large Hadron Collider (LHC) complex is being upgraded to significantly extend its scientific reach. Following the ongoing 2019–2022 long shutdown, the LHC is expected to operate during Run 3 at close to its design of 7 TeV per beam and at luminosities more than double the original design. After the next shutdown, currently foreseen in 2025–2027, the High-Luminosity LHC (HL-LHC) will run at luminosities of 5–7 × 1034 cm–2s–1. This corresponds to 140–200 simultaneous interactions per LHC bunch crossing (“pileup”), which is three to four times the Run-3 expectation and up to eight times above the original LHC design value. The ATLAS experiment, like others at the LHC, is undergoing major upgrades for the new LHC era.

Coping with very high interaction rates while maintaining low transverse-momentum (pT) thresholds for triggering on electrons and muons from the targeted physics processes will be extremely challenging at the HL-LHC. Another issue for the ATLAS experiment is that the performance of its muon tracking chambers, particularly in the end-cap regions of the detector, degrades with increasing particle rates. If the original chambers were used for the HL-LHC, it would lead to a loss in the efficiency and resolution of muon reconstruction.

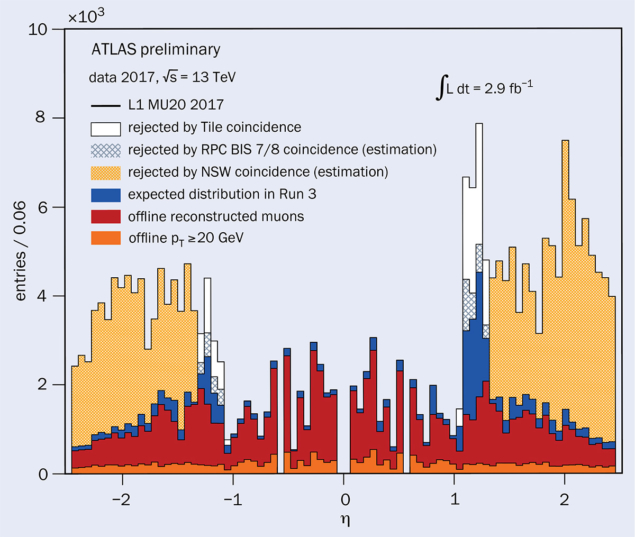

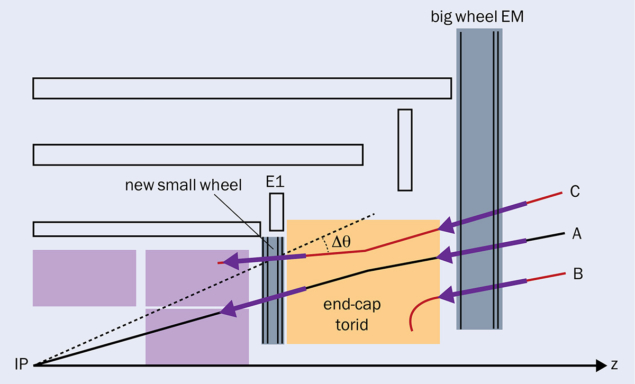

Muons are vital for efficiently triggering on, and thus precisely studying, processes in the electroweak sector such as Higgs, W and Z physics. It is therefore essential that the ATLAS detector cover as much volume as possible across the pseudorapidity distribution η = –ln tanθ/2, where θ is the angle with respect to the proton beam axis. In the central region of the detector, corresponding to a pseudorapidity |η| < 1, there is a good purity of muons originating from the proton collision point (see “Good muons” figure). In the end caps, |η| > 1.3, significant contributions, the so-called “fake” muon signals (see “Real or fake?” figure), arise from other sources. These include cavern backgrounds and muons produced in the halo of the LHC proton beams, both of which increase with larger instantaneous luminosities. Without modifications to the detector, the fake-muon trigger rates in the end caps would become unsustainable at the HL-LHC, requiring the muon pT thresholds in the Level-1 trigger to be raised substantially.

To resolve these issues, the ATLAS collaboration decided, as part of its major Phase-I upgrade, to replace the existing ATLAS muon small wheels with the “New Small Wheels” (NSW), capable of reconstructing muon track segments locally with 1 mrad resolution for both the Level-1 trigger and for offline reconstruction. The NSW will allow low-pT thresholds to be maintained for the end-cap muon triggers even at the ultimate HL-LHC luminosity.

The low-pT region for leptons is of critical importance to the ATLAS physics programme. As an example, Higgs-boson production via vector-boson fusion (VBF) is a powerful channel for precision Higgs studies, and low-pT end-cap lepton triggers are crucial for selecting H → ττ events used to study Higgs-boson Yukawa couplings. Within the current tracking detector acceptance of |η| < 2.5, the fraction VBF of H → ττ events with the leading muons having pT above 25 GeV (typical Run-2 threshold) is 60%, while this fraction drops to 28% for a pT threshold of 40 GeV (expected typical HL-LHC threshold if no changes to the detectors are made). Maintaining, or even reducing, the muon pT threshold is critical for extending the ATLAS physics programme in higher luminosity LHC operation.

Frontier technologies

The ATLAS NSW is a set of precision tracking and trigger detectors able to work at high rates with excellent spatial and time resolution using two innovative technologies: MicroMegas (MM) and small-strip thin-gap chambers (sTGC). These detectors will provide the muon Level-1 trigger system with online track segments with good angular resolution to confirm that they originate from the interaction point, reducing triggers from fake muons. They will also have timing resolutions below the 25 ns interbunch time, enabling bunch-crossing identification. With the NSW, ATLAS will keep the full acceptance of its muon tracking system at the HL-LHC while maintaining a low Level-1 pT threshold of around 20 GeV.

The ATLAS collaboration chose MM and sTGC technologies for the NSW after a detailed scrutiny of several available options. The idea was to build a robust and redundant system, using research-frontier and cost-effective technologies. Each NSW wheel has 16 sectors, with each sector containing four MM chambers and six sTGC chambers. Each sector, with a total surface area ranging from about 4 to 6 m2 , has eight sensitive planes of MM and eight of sTGC along the muon track direction. The 16 overall measurement planes allow for redundancy in the track reconstruction.

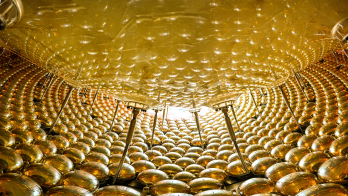

MM detectors were proposed in the 1990s in the framework of the Micro-Pattern Gaseous Detectors (MPGD) R&D programme including the RD51 project at CERN (see “Robust and redundant” figure, top). They profit from the development of photolithographic techniques for the design of high-granularity readout patterns and, in parallel, from the development of specialised front-end electronics with an increased number of channels. A dedicated R&D programme introduced, developed and realised the concept of resistive MM detectors. The main challenge for ATLAS was to scale the detectors from a few tens of cm in size to chambers of 2–3 m2 with a geometry under control at the level of tens of μm. This required additional R&D together with a very detailed mechanical design of the detectors. The resulting detectors represent the largest and most complex MPGD system ever built.

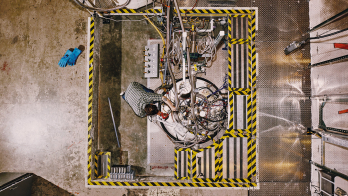

Thin-gap chambers have been used for triggering and to provide the azimuthal coordinate of muons in the ATLAS muon spectrometer end caps since the beginning of LHC operations, and were used previously in the OPAL experiment at LEP. The sTGC is an extension of established TGC technology to allow for precise online tracking that can be used both in the trigger and in offline muon tracking, with a strip pitch of 3.2 mm (see “Robust and redundant” figure, bottom).

A common readout front-end chip, named VMM, was developed for the readout of the MM strips and of the active elements of the sTGC (strips, pads and wires). This chip is a novel “amplifier-shaper-discriminator” front-end ASIC able to perform amplification and shaping, peak finding and digitisation of the detector signals. The overall system has about 2 million MM and 350,000 sTGC readout channels. The ATLAS trigger, using information from both detectors, will identify track segments pointing to the interaction region and share this information with the muon trigger.

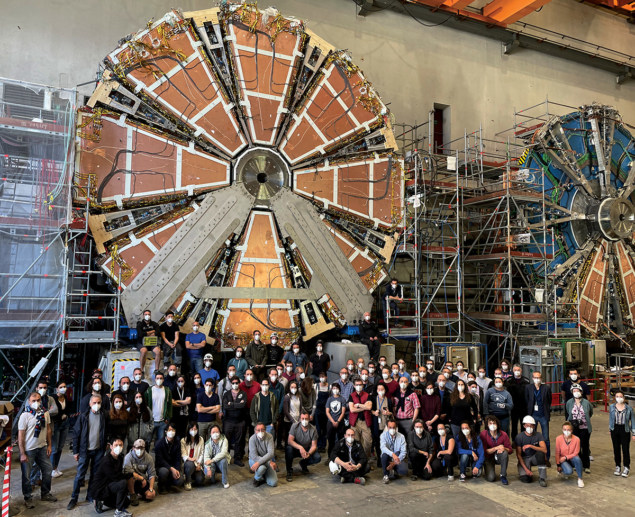

International enterprise

The construction of the 128 MM and 192 sTGC chambers has been a truly international enterprise shared among several laboratories. The construction of the MM was shared among five construction consortia in France, Germany, Greece, Italy and Russia, with infrastructure and technical expertise inherited from the construction of the ATLAS Muon Spectrometer Monitored Drift Tube chambers. The construction of the sTGC was shared among five consortia located in Canada, Chile, China, Israel and Russia, including both institutes from the original TGC construction and new ones.

A key challenge in realising both technologies was the use of large-area circuit boards produced by industry. For the case of the MM, high-voltage instabilities observed since the construction of the first large-size prototypes were mostly due to the quality of the printed circuit boards. Two aspects in particular were investigated: the cleanliness of the surfaces, and the actual measured values of the board resistivity that were in many cases not large enough to prevent electrical discharges in the detector. For both problems, detailed mitigation protocols were developed and shared among the consortia: a cleaning protocol including polishing and washing of all the surfaces and a “passivation” procedure designed to mask detector regions with lower resistance where most of the discharges were observed to take place.

For the sTGC, the principal difficulty in the circuit-board production was maintaining mechanical tolerances and electrical integrity over the large areas. Considerable R&D and quality control were required before and during the board production, and when combined with X-ray measurements at CERN the sTGC layers are aligned to better than 100 μm.

Along with the chamber construction, several tests were carried out at the construction sites to evaluate the chamber quality. Some of the first full-size prototypes together with the first production chambers were exposed to test beams. All the sTGC chambers and a large fraction of the MM chambers were also tested at CERN’s GIF++ irradiation facility to evaluate their behaviour under a particle rate comparable to the one expected at the HL-LHC.

The integration of both MM and sTGC chambers to form the wheel sectors took place at CERN from 2018 to 2021. Four MM chambers form a double-wedge, assembled accounting for the severe alignment requirements, which is then equipped with all the necessary services and the final front-end electronics (see “Taking stock” image). The systems were fully tested in a dedicated cosmic-ray test stand to verify the functionality of the detector and to evaluate the detector efficiency. For the sTGCs, three chambers were glued to fibreglass frames using precision inserts on a granite table to form a wedge. After long-term high-voltage tests, the sTGC wedges were equipped with front-end electronics, cooling, and readout cables and fibres. All the sTGC chambers were tested with cosmic rays at the construction sites, and a few were also tested at CERN.

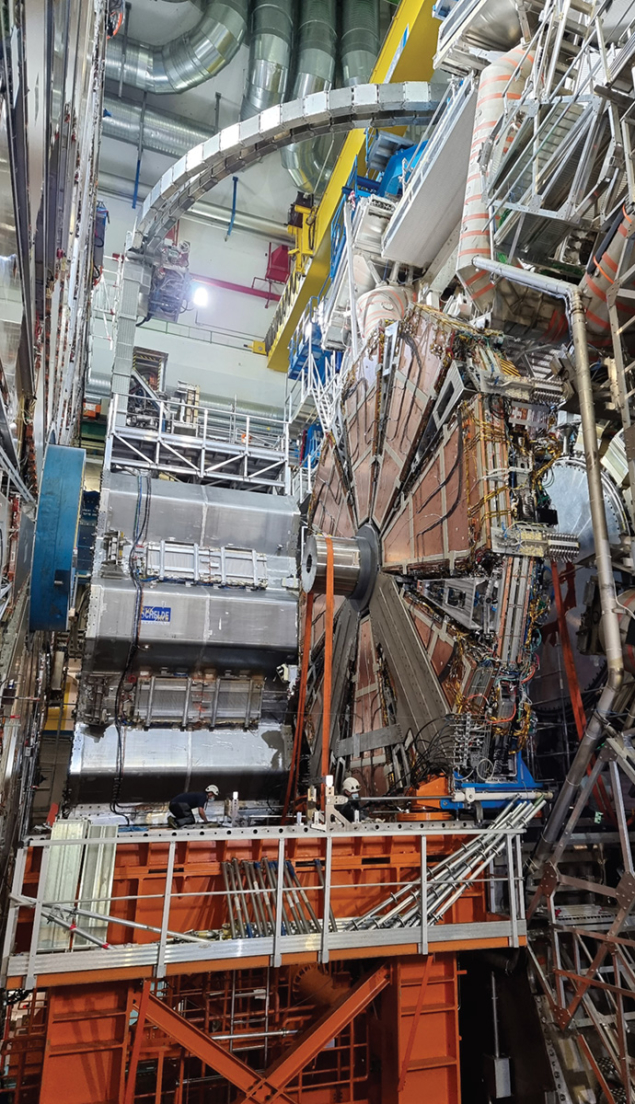

To form each sector, two sTGC wedges and one MM double-wedge were sandwiched together. The sectors were then precisely mounted on “spokes” installed on the large shielding disks that form the NSW wheels, along with a precision optical alignment system that allows the chamber positions to be tracked by ATLAS in real time (see “Revolutions” image). After completing final electrical, cooling and gas connections during 2020 and 2021, all sectors were commissioned and tested on the wheel. One unexpected problem encountered on the first sectors on wheel A was the presence of a noise level in the front-end electronics that was significantly higher than observed during integration. A large and ultimately successful effort was put in place to mitigate this new challenge, for example by improving the grounding and shielding, and adding filtering to the power supplies.

This final success follows more than a decade of research, design and construction by the ATLAS collaboration. The NSW initiative dates to early LHC operation, around 2010, and the technical design report was approved in 2013, with construction preparation starting soon afterwards. The impact of the COVID-19 pandemic on the NSW construction schedule was significant, mostly at the construction sites, where delays of up to a few months were accrued, but the project is now on schedule for completion during the current LHC shutdown.

The endgame

Prior to lowering the NSW into the ATLAS experimental cavern, other infrastructure was installed to prepare for detector operation. The service caverns were equipped with electronics racks, high-voltage and low-voltage power supplies, gas distribution systems, cooling infrastructure for electronics, as well as control and safety systems. Where possible, existing infrastructure from the previous ATLAS small wheels was repurposed for the NSW.

ATLAS is now close to the completion of its Phase-I upgrade goal of having both NSW-A and NSW-C installed for the start of Run 3

On 6 July, the first wheel, NSW-A, was shipped from Building 191 on the CERN site to LHC Point 1 and then, less than a week later, lowered into its position in ATLAS (see “In place” image). With the first NSW in its final position, the extensive campaign of connecting low voltage, high voltage, gas, readout fibres and electronics cooling was the next step. These connections were completed for NSW-A in July and August 2021, and an extensive commissioning programme is ongoing. In addition to powering both the chambers and the readout electronics, the integration of the NSW into the ATLAS controls and data-acquisition system is occurring at Point 1. NSW-A is planned to be fully integrated into ATLAS for the LHC pilot-beam run in October 2021, and then NSW-C will be lowered and installed.

Despite a tight schedule, ATLAS is now close to the completion of its Phase-I upgrade goal of having both NSW-A and NSW-C installed for the start of Run 3. The period up to February 2022 will be needed to complete commissioning and testing. Starting from March 2022, a very important “commissioning with beam” phase will be carried out to ensure stable collisions in Run 3. Even with the challenges of developing new technologies while working across a dozen countries during the COVID-19 pandemic, the ATLAS New Small Wheel upgrade will be ready for the exciting, new higher luminosities that will open up a novel era of LHC physics.