Some 120 physicists gathered in Orsay on 13–14 December 2018 for a workshop on additive manufacturing – popularly called 3D printing – with metals. The goal was to review the work being done in Europe (particularly at CERN, CEA and CNRS) on the application of the technique to high-energy physics and astrophysics.

3D printing makes possible novel and optimised designs that would be difficult to create with conventional methods. Embedded radio-frequency (RF) cavities such as those featured in spiral-shaped cooling channels are one example. Another comes from detector design: mesh structures, as required for many gas-filled ionisation tracking detectors, are often difficult to manufacture with traditional methods as the removal of material in one part of the mesh may destroy another part of it; but they are easy to build with additive manufacturing.

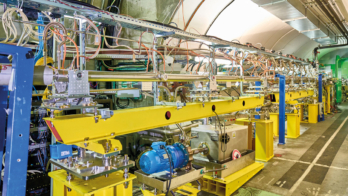

Despite the remaining challenges, which relate to ultra-high-vacuum properties, mechanical strength, electrical conductivity, new alloys and post-processing, the technique is beginning to be used for working accelerator components. Participants of the Orsay event heard about the beam test at an accelerator (LAL’s photoinjector PHIL), of a beam position monitor and about the performances of RF antennas designed at Université de Rennes for future space missions. Plans for employing additive manufacturing at future accelerators and HEP experiments were also discussed.

Although metal additive manufacturing is currently limited to a few applications, the workshop, which was the first of its kind, showed that there is strong potential for it to play a larger role in the coming years.