CERN’s vacuum group has completed an intense period of activity during Long Shutdown 2 to prepare the accelerator complex for more luminous operation through LHC Run 3 and beyond, describes Paolo Chiggiato.

The second long-shutdown of the CERN accelerator complex (LS2) is complete. After three years of intense works at all levels across the accelerators and experiments, beams are expected in the LHC in April. For the accelerators, the main LS2 priorities were the consolidation of essential safety elements (dipole diodes) for the LHC magnets, several interventions for the High-Luminosity LHC (HL-LHC) and associated upgrades of the injection chain via the LHC Injectors Upgrade project. Contributing to the achievement of these and many other planned parallel activities, the CERN vacuum team has completed an intense period of work in the tunnels, workshops and laboratories.

Particle beams require extremely low pressure in the pipes in which they travel to ensure that their lifetime is not limited by interactions with residual gas molecules and to minimise backgrounds in the physics detectors. During LS2, all of the LHC’s arcs were vented to the air after warm-up to room temperature and all welds were leak-checked after the diode consolidation (with only one leak found among the 1796 tests performed). The vacuum team also replaced or consolidated around 150 turbomolecular pumps acting on the cryogenic insulation vacuum. In total, 2.4 km of non-evaporable-getter (NEG)-coated beampipes were also opened to the air at room temperature – an exhaustive programme of work spanning mechanical repair and upgrade (across 120 weeks), bake-out (90 weeks) and NEG activation (45 weeks). The vacuum level in these beampipes is now in the required range, with most of the pressure readings below 10–10 mbar.

The vacuum control system was also significantly improved by reducing single points of failure, removing confusing architectures and, for the first time, using mobile vacuum equipment controlled and monitored wirelessly. In view of the higher LHC luminosity and the consequent higher radioactivity dose during Run 3 and beyond, the vacuum group has developed and installed new radiation-tolerant electronics controlling 100 vacuum gauges and valves in the LHC dispersion suppressors. This was the first step of a larger campaign to be implemented in the next long-shutdown, including the production of 1000 similar electronics cards for vacuum monitoring. In parallel, the control software was renewed. This included the introduction of resilient, scalable and self-healing web-based frameworks used by the biggest names in industry.

In the LHC experimental areas, the disassembling of the vacuum chambers at the beginning of LS2 required 93 interventions and 550 person-hours of work in the caverns, with the most impressive change in vacuum hardware implemented in CMS and LHCb (see “Interaction points” images). In CMS, a new 7.3 m-long beryllium beam-pipe with an internal diameter of 43.4 mm was installed and 12 new aluminium chambers were manufactured, surface-finished and NEG-coated at CERN. The mechanical installation, including alignments, pump-down and leak detection, took two months, while the bake-out and venting with ultra-pure neon required a further month. In LHCb, the vacuum team contributed to the new Vertex Locator (VELO). Its “RF box” – a delicate piece of equipment filled with silicon detectors, electronics and cooling circuits designed to protect the VELO without affecting the beams – is situated just a few mm from the beam with an aluminium window thinned down to 150 μm by chemical etching and then NEG-coated. As the VELO encloses the RF box and both volumes are under separated vacua, the pump-down is a critical operation because pressure differences across the thin window must be lower than 10 mbar to ensure mechanical integrity. The last planned activity for the vacuum team in LS2, the bake-out of the ATLAS beam pipes, took place in February.

Vacuum challenges

From the list of successful achievements, it could be assumed that vacuum activities in LS2 have gone smoothly, with the team applying well known procedures and practicing knowledge accumulated over decades. However, as might be expected when working with several teams in parallel and at the limits of technology, with around 100 km of piping under vacuum for the LHC alone, this is far from the case. Since the beginning of LS2, CERN vacuum experts have experienced several technical issues and obstacles, a few of which deserve a mention (see “Overcoming the LS2 vacuum obstacles” panel). All these headaches have challenged our regular way of working and allowed us to reflect on procedures, communication and reporting, and technical choices.

But the real moment of truth is still yet to come, when the intensity of the LHC beams reaches the new nominal value boosted by the upgraded injectors. Under the spotlight will be surface electron emission, which drives the formation of electron clouds and their consequences, including beam instabilities and heat load on the cryogenic system. The latter showed anomalously high values during Run 2, with strong inhomogeneity along the ring indicating an uneven surface conditioning. The question is what will happen to the heat load during Run 3? Thanks to the effort and achievements of a dedicated taskforce, the scrubbing and following physics runs will provide a detailed answer in a few months. Last year, the task force installed additional instrumentation in the cryogenic lines in selected positions and, after many months of detective work, identified the most probable culprit of the puzzling heat-load values: the formation of a non-native copper oxide layer during electron bombardment of hydroxylated copper surfaces at cryogenic temperatures. UV exposure in selected gas, local bakeout and plasma etching are among the mitigation techniques we are going to investigate.

The HL-LHC horizon

LS2 might only just have finished but we are already thinking about LS3 (2026–2028), whose leitmotif will be the finalisation of the HL-LHC project. Thanks to more focused beams at the collision points and an increased proton bunch population, the higher beam luminosity at CMS and ATLAS (peaking at a levelled value of 5 × 1034 cm–2s–1) will enable an integrated luminosity of 3000 fb–1 in 12 years. For the HL-LHC vacuum systems, this requires a completely new design of the beam screens in the focusing area of the experiments, the implementation of carbon thin-film coatings in the unbaked beampipes to cope with the lower secondary electron yield threshold, and radiation-compatible equipment near the experiments and radiation-tolerant electronics down to the dispersion suppressor zones.

Overcoming the LS2 vacuum obstacles

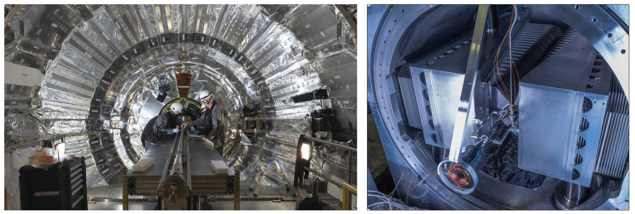

Forgotten sponge

During the first beam-commissioning of the PS, anomalous high proton losses were detected, generating pressure spikes and a high radioactive dose near one of the magnets. An endoscopic inspection (see image above, left) revealed the presence of an orange sponge that had been used to protect the vacuum chamber extremities before welding (and which had been left behind due to a miscommunication between the teams involved), blocking the lower half of the beam pipe. After days of investigation with the beams and interventions by technicians, the chamber was cut open and the offending object removed.

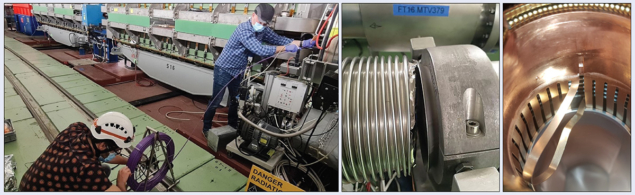

Leaky junctions

Having passed all tests before they were installed, new corrugated thin-walled vacuum chambers installed in the Proton Synchrotron Booster to reduce eddy-current effects suffered vacuum leaks after a few days of magnet pulsing. The leaks appeared in lip-welded junctions in several chambers, indicating a systematic production issue. Additional spare chambers were produced and, as the leaks remain tolerable, a replacement is planned during the next year-end technical stop. Until then, this issue will be the Sword of Damocles on the heads of the vacuum teams in charge of the LHC’s injectors.

Powering mismatch

During the first magnet tests of the TT2 transfer line, a vacuum sector was suddenly air-vented. The support of the vacuum chambers was found to be broken; two bellows were destroyed (see image, middle), and the vacuum chamber twisted. The origin of the problem was a different powering scheme of the magnet embedding the chamber: faster magnetic pulses generated higher eddy-current and Lorentz forces that were incompatible with the beampipe design and supports. It was solved by inserting a thin insulation layer between vacuum flanges to interrupt the eddy current, a practice common in other parts of the injectors.

QRL quirks

The LHC’s helium transfer lines (QRL) require regular checks, especially after warm-up and cool-down. During LS2, the vacuum team installed two additional turbomolecular pumps to compensate for the rate increase of a known leak in sector B12, allowing operation until at least the next long-shutdown. Another troubling leak which opened only for helium pressures above 7 bar was detected in a beam-screen cooling circuit. Fixing it would have required the replacement of the nearby magnet but the leak turned out to be tolerable at cryogenic temperatures, although its on/off behaviour remains to be fully elucidated.

Damaged disks

Installed following the incident in sector 3–4 shortly after LHC startup, the beam vacuum in the LHC arcs is protected against overpressure by 832 “burst disks”. A 30 μm-thick stainless- steel disk membrane nominally breaks when the pressure in the vacuum system is 0.5 bar higher than the tunnel air pressure. Despite the careful venting procedure, 19 disks were either broken or damaged before the re-pumping of the arcs. Subsequent lab tests showed no damage in spare disks cycled 30 times at 1.1 bar. The vacuum teams replaced the damaged disks and are trying to understand the cause.

Buckled fingers

Before cool-down, a 34 mm-diameter ball fitted with a 40 MHz transmitter is pushed through the LHC beam pipes to check for obstacles. The typical defect is a buckling of the RF fingers in the plug-in modules (PIMs) that maintain electrical continuity as the machine thermally contracts. Unfortunately, in two cases the ball arrived damaged, and it took days to collect and identify all the broken pieces. A buckled finger was successfully found in sector 8-1, but another in sector 2-3 (see image, right) was revealed only when the pilot beam circulated. This forced a re-warming of the arc, venting of the beampipe and the replacement of the damaged PIM, followed by additional re-cooling and aperture and electrical tests.

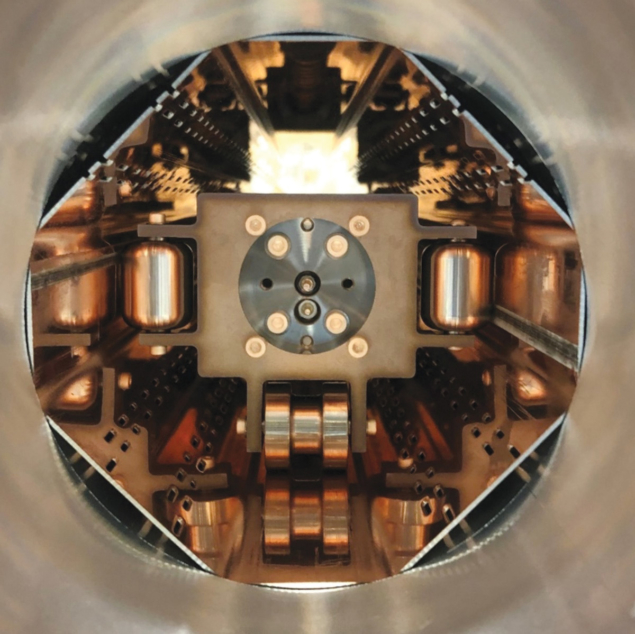

The first piece of vacuum equipment concerned is the “VAX”: a compact set of components, pumps, valves and gauges installed in an area of limited access and relatively high radioactivity between the last focusing magnet of the accelerator and the high-luminosity experiments. The VAX module is designed to be fully compatible with robot intervention, enabling leak detection, gasket change and complete removal of parts to be carried out remotely and safely.

Despite the massive shielding between the experiment caverns and the accelerator tunnels, secondary particles from high-energy proton collisions can reach accelerator components outside the detector area. At nominal HL-LHC luminosity, up to 3.8 kW of power will be deposited in the tunnel on each side of CMS and ATLAS, of which 1.2 kW is intercepted by the 60 m-long sequence of final focusing magnets. Such a power is incompatible with magnet cooling at 1.9 K and, in the long run, could cause the insulation of the superconducting cables to deteriorate. To avoid this issue, the vacuum team designed a new beam screen equipped with tungsten-alloy shielding so that at least half of the power is captured before being transmitted to the magnet cold mass.

All eyes are on the successful restart of the CERN accelerator complex and the beginning of LHC Run 3

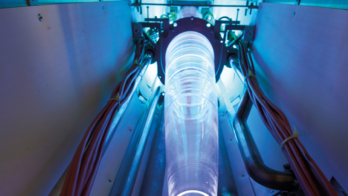

The new HL-LHC beam screens took several years of design and manufacturing optimisation, multi-physics simulations and tests with prototypes. The most intense study concerned the mechanical integrity of this complicated object when the hosting magnet undergoes a quench, causing the current to drop from nearly 20 kA to 0 kA in a few tenths of a second. The manufacturing learning phase is now complete and the beam-screen facility will be ready this year, including the new laser-welding robot and cryogenic test benches. Carbon coating is the additional novelty of the HL-LHC beam screens, with the purpose of suppressing electron clouds (see “Beam screen” image). At the beginning of LS2 the first beam screens were successfully coated in situ, involving a small robot carrying carbon and titanium targets, and magnets for plasma confinement during deposition.

The vacuum team is also involved in the production of crab cavities, another breakthrough brought by the HL-LHC project. The surfaces of these complex-shaped niobium objects are treated by a dedicated machine that can provide rotation while chemically polishing with a mixture of nitric, hydrofluoric and phosphoric acids. The vacuum system of the cryomodules in which the cavities are cooled at 2 K was also designed at CERN.

Outlook

Vacuum technology for particle accelerators has been pioneered by CERN since its early days, with the Intersecting Storage Rings bringing the most important breakthroughs. Over the decades, the CERN vacuum group has merged surface-physics specialists, thin-film coating experts and galvanic-treatment professionals, together with teams of designers and colleagues dedicated to the operation of large vacuum equipment. In doing so, CERN has become one of the world’s leading R&D centres for extreme vacuum technology, contributing to major existing and future accelerator projects at CERN and beyond. With the HL-LHC in direct view, the vacuum team looks forward to attacking new challenges. For now, though, all eyes are on the successful restart of the CERN accelerator complex and the beginning of LHC Run 3.

Further reading

O Aberle et al. 2020 CERN-2020-010.

J Coupard et al. (eds.) 2014 CERN-ACC-2014-0337.

F Meuter et al. 2020 J. Phys. Conf. Ser. 1559 012072.

V Petit et al. 2021 Nat. Commun. Phys. 4 192.