Established 30 years ago with a linear electron–positron collider in mind, the TESLA Technology Collaboration has played a major role in the development of superconducting radio-frequency cavities and related technologies for a wide variety of applications.

Energetic beams of charged particles are essential for high-energy physics research, as well as for studies of nuclear structure and dynamics, and deciphering complex molecular structures. In principle, generating such beams is simple: provide an electric field for acceleration and a magnetic field for bending particle trajectories. In practice, however, the task becomes increasingly challenging as the desired particle energy goes up. Very high electric fields are required to attain the highest energy beams within practical real-estate constraints.

The most efficient way to generate the very high electric fields in a vacuum environment required to transport a beam is to build up a resonant excitation of radio waves inside a metallic cavity. There is something of an art to shaping such cavities to “get the best bang for the buck” for a particular application. The radio-frequency (RF) fields are inherently time-varying, and bunches of charged particles need to arrive with the right timing if they are to see only forward-accelerating electric fields. Desirable very high resonant electric fields (e.g. 5–40 MV/m) require the existence of very high currents in the cavity walls. These currents are simply not sustainable for long durations using even the best normal-conducting materials, as they would melt from resistive heating.

Superconducting materials, on the other hand, can support sustainable high-accelerating gradients with an affordable electricity bill. Early pioneering work demonstrating the first beam-acceleration using superconducting radio-frequency (SRF) cavities took place in the late 1960s and early 1970s at Stanford, Caltech, the University of Wuppertal and Karlsruhe. The potential for real utility was clear, but techniques and material refinements were needed. Several individual laboratories began to take up the challenge for their own research needs. Solutions were developed for electron acceleration at CESR, HERA, TRISTAN, LEP II and CEBAF, while heavy-ion SRF acceleration solutions were developed at Stony Brook, ATLAS, ALPI and others. The community of SRF accelerator physicists was small but the lessons learned were consistently shared and documented. By the early 1990s, SRF technology had matured such that complex large-scale systems were credible and the variety of designs and applications began to blossom.

The TESLA springboard

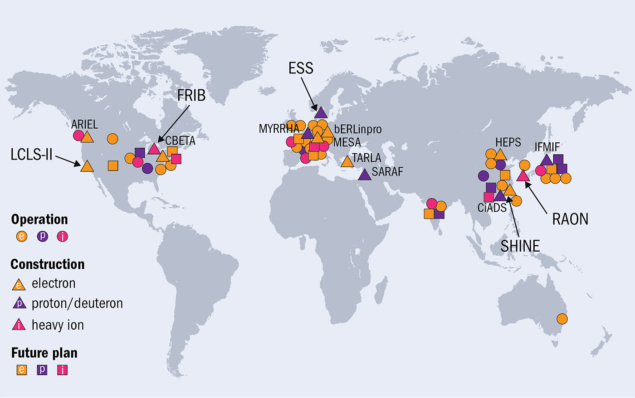

In 2020, the TESLA Technology Collaboration (TTC) celebrates 30 years of collaborative efforts on SRF technologies. The TTC grew out of the first international TESLA (TeV Energy Superconducting Linear Accelerator) workshop, which was held at Cornell University in July 1990. Its aim was to define the parameters for a superconducting linear collider for high-energy physics operating in the TeV region and to explore how to increase the gradients and lower the costs of the accelerating structures. It was clear from the beginning that progress would require a large international collaboration, and the Cornell meeting set in motion a series of successes that are ongoing to this day – including FLASH and the European XFEL at DESY. The collaboration also led to proposals for several large SRF-based research facilities including SNS, LCLS-II, ESS, PIP-II and SHINE, as well as a growing number of smaller facilities around the world.

Accelerating gradients above 40 MV/m are now attainable with niobium

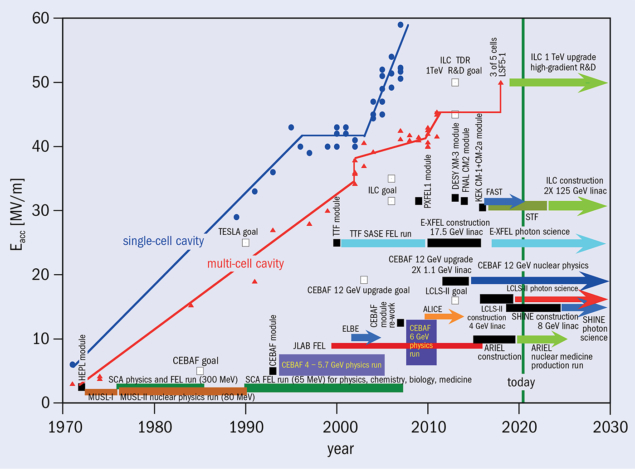

At the time of the first TESLA collaboration meeting, the state-of-the-art in accelerating gradients for electrons was around 5 MV/m in the operating SRF systems of TRISTAN at KEK, HERA at DESY, LEP-II at CERN and CEBAF at Jefferson Lab (JLab), which were then under construction. Many participants in this meeting agreed to push for a five-fold increase in the design accelerating gradient to 25 MV/m to meet the dream goal for TESLA at a centre-of-mass energy of 1 TeV. The initial focus of the collaboration was centred on the design, construction and commissioning of a technological demonstrator, the TESLA Test Facility (TTF) at DESY. In 2004, SRF was selected as the basis for an International Linear Collider (ILC) design and, shortly afterwards, the TESLA collaboration was re-formed as the TESLA Technology Collaboration with a scope beyond the original motivation of high-energy physics. The TTC, with its incredible worldwide collaboration spirit, has had a major role in the growth of the SRF community, facilitating numerous important contributions over the past 30 years.

30 years of gradient march

Conceptually, the objective of simply providing “nice clean” niobium surfaces on RF structures seems pretty straightforward. Important subtleties begin to emerge, however, as one considers that the high RF-surface currents required to support magnetic fields up to ~100 mT flow only in the top 100 nm of the niobium surface, which must offer routine surface resistances at the nano-ohm level over areas of around 1 m2. Achieving blemish-free, contamination-free surfaces that present excellent crystal lattice structure even in this thin surface layer is far from easy.

The march of progress in cavity gradient for linacs and the many representative applications over the past 50 years (see figure “Gradient growth”) are due to breakthroughs in three main areas: material purity, fabrication and processing techniques. The TTC had a major impact on each of these areas.

With some notable exceptions, bulk niobium cavities fabricated from sheet stock material have been the standard, even though the required metallurgical processes present challenges. Cycles of electron-beam vacuum refining, rolling, and intermediate anneals are provided by only a few international vendors. Pushing up the purity of deliverable material required a concerted push, resulting in the avoidance of foreign material inclusions, which can be deadly to performance when uncovered in the final step of surface processing. The figure-of-merit for purity is the ratio of room-temperature to cryogenic normal-conducting resistivity – the residual resistance ratio, RRR. The common cavity-grade niobium material specification has thus come to be known as high-RRR grade.

Another later pursuit of pure niobium is the so-called “large grain” or “direct-from-ingot” material. Rather than insist on controlled ~30 µm grain-size distribution (grains being microcrystals in the structure), this material uses sheet slices cut directly from large ingots having much larger, but arbitrarily sized, grains. Although not yet widely used, this material has produced the highest gradient TESLA-style cavities to date – 45 MV/m with a quality factor Q0 > 1010. Here again, though the topic was initiated at JLab, this fruitful work was accomplished via worldwide international collaborations.

As niobium is a refractory metal that promptly cloaks itself with about 4 nm of dielectric oxide, welding niobium components has to be performed by vacuum electron beam welding. Collaborative efforts in Europe, North America and Asia refined the parameters required to yield consistent niobium welds. The community gradually realised that extreme cleanliness is required in the surface-weld preparation, since even microscopic foreign material will be vaporised during the weld process, leaving behind small voids that become performance-limiting defects.

Having the best niobium is not sufficient, however. Superconductors have inherent critical magnetic field limitations, or equivalently local surface-current density limitations. Because the current flow is so shallow, local magnetic field enhancements induced by microscopic topography translate into gradient-limiting quench effects. Etching of fabricated surfaces has routinely required a combination of hydrofluoric and nitric acids, buffered with phosphoric acid. This exothermic etching process inherently yields step-edge faceting at grain boundaries, which in turn creates local, even nanoscopic, field enhancements, anomalous losses and quenches as the mean surface field is increased. A progression of international efforts at KEK, DESY, CEA-Saclay and JLab eliminated this problem through the development of electro-polishing techniques. Following a deeper understanding of the underlying electrochemistry, accelerating gradients above 40 MV/m are now attainable with niobium.

Another vexing problem that TTC member institutions helped to solve was the presence of “Q-drop” in the region of high surface magnetic field, for which present explanations point to subtle migration of near-surface oxygen deeper into the lattice, where it inhibits the subsequent formation of lossy nanohydrides on cool-down. Avoidance of nanohydrides, whose superconductivity by proximity effect breaks down in the Q-drop regime, is required to sustain accelerating gradients above 25 MV/m for some structures.

Cleaning up

TTC members have also shared analyses and best practices in cleaning and cleanroom techniques, which have evolved dramatically during the past 30 years. This has helped to beat down the most common challenge for developers and users of SRF accelerating cavities: particulate-induced field emission, whereby very high peak surface electric fields can turn even micron-scale foreign material into parasitic electron field emission sources, with resulting cryogenic and radiation burdens. Extended interior final rinsing with high-pressure ultra-pure water prior to cavity assembly has become standard practice, while preparation and assembly of all beamline vacuum hardware under ISO 4 cleanroom conditions is necessary to maintain these clean surfaces for accelerator operations.

The most recent transformation has come with the recognition that interstitial doping of the niobium surface with nitrogen can reduce SRF surface resistance much more than was dreamed possible, reducing the cryogenic heat load to be cooled. While still the subject of material research, this new capability was rapidly adopted into the specification for LCLS-II cavities and is also being considered for an ILC. The effort started in the US and quickly propagated internationally via the TTC, for example in cavity tests at the European Spallation Source (see “Vertical test” image). Earlier this year, Q-values of 3–4 × 1010 at 2 K at 30 MV/m were reported in TESLA-style cavities – representing tremendous progress, but with much optimisation still to be carried out.

One of the main goals of the TTC has been to bridge the gap between state-of-the-art R&D on laboratory prototypes and actual accelerator components in operating facilities, with the clear long-term objective to enable superconducting technology for a TeV-scale linear collider. This objective demanded a staged approach and intense work on the development of all the many peripherals and subcomponents. The collaboration embraced a joint effort between the initial partners to develop the TTF at DESY, which aimed to demonstrate reliable operation of an electron superconducting linac at gradients above 15 MV/m in “vector sum” control – whereby many cavities are fed by a single high-power RF source to improve cost effectiveness. In 1993 the collaboration finalised a 1.3 GHz cavity design that is still the baseline of large projects like the European XFEL, LCLS-II and SHINE, and nearly all L-band-based facilities.

Towards a linear collider

An intense collaborative effort started for the development of all peripheral components, for example power couplers, high-order mode dampers, digital low-level RF systems and cryomodules with unprecedented heat load performances. Several of these components were designed by TTC partners in an open collaborative and competitive effort, and a number of them can be found in existing projects around the world. The tight requirements imposed by the scale of a linear collider required an integrated design of the accelerating modules, containing the cavities and their peripheral components, which led to the concept of the “TESLA style” cryomodules, variants of which provide the building blocks of the linacs in TTF, European XFEL, LCLS-II and SHINE.

The success of the TTF, which delivered its first beam in 1997, led it to become the driver for a next-generation light source at DESY, the VUV-FEL, which produced first light in 2005 and which later became the FLASH facility. The European XFEL built on this strong heritage, its large scale demanding a new level of design consolidation and industrialisation. It is remarkable to note that the total number of such TESLA-style cavities installed or to be installed in presently approved accelerators is more than 1800. Were a 250 GeV ILC to go ahead in Japan, approximately 8000 such units would be required. (Note that an alternative proposal for a high-energy linear collider, the Compact Linear Collider, relies on a novel dual-beam acceleration scheme that does not require SRF cavities.)

Since the partners collaborating on the early TESLA goal of a linear collider were also involved in other national and international projects for a variety of applications and domains, the first decade of the 21st century saw the TTC broaden its reach. For example, we started including reports from other projects, most notably the US Spallation Neutron Source, and gradually opened to the community working on low-beta ion and proton superconducting cavities, such as the half-wave resonator string collaboratively developed at Argonne National Lab and now destined for use in PIP-II at Fermilab (see “Low-beta cavities” image). TTC meetings include topical sessions with industries to discuss how to shorten the path from development to production. Recently, the TTC has also begun to facilitate collaborative exchanges on alternative SRF materials to bulk niobium, such as Nb3Sn and even hybrid multilayer films, for potential accelerator applications.

Sustaining success

The mission of the TTC is to advance SRF technology R&D and related accelerator studies across the broad diversity of scientific applications. It is to provide a bridge for open communication and sharing of ideas, development and testing across associated projects. The TTC supports and encourages the free and open exchange of scientific and technical knowledge, engineering designs and equipment. Furthermore, it is based on cooperative work on SRF accelerator technology by research groups at TTC member institution laboratories and test facilities. The current TTC membership consists of 60 laboratories and institutes in 12 countries across Europe, North America and Asia. Since progress in cavity performance and related SRF technologies is so rapid, the major TTC meetings have been frequent.

Particle accelerators using SRF technologies have been applied widely, from small facilities for medical applications up to large-scale projects for particle physics, nuclear physics, neutron sources and free-electron lasers (see “Global view” figure). Five large-scale (> 100 cavities) SRF projects are currently under construction in three regions: ESS in Europe, FRIB and LCLS-II in the US, and SHINE (China) and RAON (Korea) in Asia. Close international collaboration will continue to support progress in these and future projects, including SRF thin-film technology relevant for a possible future circular electron–positron collider. Perhaps the next wave of SRF technology will be the maturation of economical small-scale applications with high multiplicity and international standards. As an ultimate huge future SRF project, realising an ILC will indeed require sustained broad international collaboration.

The open and free-exchange model that for 30 years has enabled the TTC to make broad progress in SRF technology is a major contribution to science diplomacy efforts on a worldwide scale. We celebrate the many creative and collaborative efforts that have served the international community well via the TESLA Technology Collaboration.