New superconductivity training network to develop key skills.

Image credit:R Hradile/RvS Media.

Heike Kamerlingh Onnes won his Nobel prize back in 1913 two years after the discovery of superconductivity; Georg Bednorz and Alexander Müller won theirs in 1987, just a year after discovering high-temperature superconductors. Putting these major discoveries into use, however, has been a lengthy affair, and it is only in the past 30 years or so that demand has emerged. Today, superconductors represent an annual market of around $1.5 billion, with a high growth rate, yet a plethora of opportunities remains untapped.

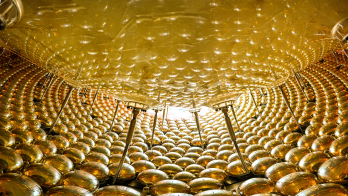

Developing new superconducting materials is essential for a possible successor to the LHC currently being explored by the Future Circular Collider (FCC) study, which is driving a considerable effort to improve the performance and feasibility of large-scale magnet production. Beyond fundamental research, superconducting materials are the natural choice for any application where strong magnetic fields are needed. They are used in applications as diverse as magnetic resonance imaging (MRI), the magnetic separation of minerals in the mining industry and efficient power transmission across long distances (currently being explored by the LIPA project in the US and AmpaCity in Germany).

The promise for future technologies is even greater, and overcoming our limited understanding of the fundamental principles of superconductivity and enabling large-quantity production of high-quality conductors at affordable prices will open new business opportunities. To help bring this future closer, CERN has initiated the European Advanced Superconductivity Innovation and Training project (EASITrain) to prepare the next generation of researchers, develop innovative materials and improve large-scale cryogenics (easitrain.web.cern.ch). From January next year, 15 early stage researchers will work on the project for three years, with the CERN-coordinated FCC study providing the necessary research infrastructure.

Global network

EASITrain establishes a global network of research institutes and industrial partners, transferring the latest knowledge while also equipping participants with business skills. The network will join forces with other EU projects such as ARIES, EUROTAPES (superconductors), INNWIND (a 10–20 MW wind turbine), EcoSWING (superconducting wind generator), S-PULSE (superconducting electronics) and FuSuMaTech (a working group approved in June devoted to the high-impact potential of R&D for the HL-LHC and FCC), and aims to profit from the well-established Test Infrastructure and Accelerator Research Area Preparatory Phase (TIARA) platform. EASITrain also links with the Marie Curie training networks STREAM and RADSAGA, both hosted by CERN.

Operating within the EU’s H2020 framework, one of EASITrain’s targets is energy sustainability. Performance and efficiency increases in the production and operation of superconductors could lead to 10–20 MW wind turbines, for example, while new efficient cryogenics could reduce the carbon footprint of industries, gas production and transport. EASITrain will also explore the use of novel superconductors, including high-temperature superconductors, in advanced materials for power-grid and medical applications, and bring together technical experts, industrial representatives and specialists in business and marketing to identify new superconductor applications. Following an extensive study, three specific application areas have been identified: uninterruptible power supplies; sorting machines for the fruit industry; and large loudspeaker systems. These will be further explored during a three-day “superconductivity hackathon” satellite event at EUCAS17, organised jointly with CERN’s KT group, IdeaSquare, WU Vienna and the Fraunhofer Institute.

Together with the impact that superconductors have had on fundamental research, these examples show the unexpected transformative potential of these still mysterious materials and emphasise the importance of preparing the next generation for the challenges ahead.

Hackathon application destinations

Uninterruptible power supply (UPS). UPS systems are energy-storage technologies that can take on and deliver power when necessary. Cloud-based applications are leading to soaring data volumes and an increasing need for secure storage, driving growth among large data centres and a shift towards more efficient UPS solutions that are expected to carve a slice of an almost $1 billion and growing market. Current versions are based on batteries with a maximum efficiency of 90%, but superconductor-based implementations based on flywheels will ensure a continuous and longer-lived power supply, minimising data loss and maximising server stability.

Sorting machines for the fruit industry. Tonnes of fruit have to be disposed of worldwide because current technologies based on spectroscopy are not able to determine the maturity level of fruit sufficiently accurately, with techniques also offering limited information about small-sized fruit. Superconductors would enable NMR-based scanning systems that allow producers to accurately and non-destructively determine valuable properties such as ripeness, absence of seeds and, crucially, the maturity of fruit. In 2016, sorting-machine manufacturers made profits of $360 million selling products analysing apples, pears and citrus fruit, and the market has experienced a growth of about 20% per year.

Large loudspeaker systems. The sound quality of powerful loudspeakers, particularly PA systems for music festivals and stadiums, could enter new dimensions by using superconductors. Higher electrical resistance leads to poorer sound quality, since speakers need to modify the strength of a magnetic field rapidly to adapt to different frequency ranges. Superconductivity also allows smaller magnets to be used, making them more compact and transportable. A major concern among European manufacturers has been the search for the next big step in loudspeaker evolution, to defend against competition from Asia, and the size and quality of large speakers is now a major driver of the $500 million industry.