Novel and established detectors that push technologies to new heights will allow the CMS collaboration to fully exploit the HL-LHC physics potential. Anne Dabrowski, Frank Hartmann and Paolo Rumerio give a snapshot of the Phase II upgrade progress.

The High-Luminosity LHC (HL-LHC), due to start operations in 2029, will deliver about 10 times more data than has been accumulated during the previous LHC runs. The CMS collaboration is getting ready to profit from sub-percent precision on many Standard Model (SM) processes and to probe physics beyond the SM, both directly and through studies of higher-order effective operators. Studying rare processes, such as double-Higgs production, rare tau-lepton decays and Higgs couplings to second-generation fermions, will also be a central part of the programme. New ideas will certainly lead to improvements beyond the statistical scaling of uncertainties, bringing us closer to observing these rare processes. While high-precision tests of the SM will surely be the ultimate legacy of the LHC experiments, CMS will also keep searching for clear signs of new physics by investigating the many signatures accessible at the HL-LHC.

To exploit the HL-LHC physics potential, the CMS collaboration is building an optimised detector that pushes technologies to new heights. This major “Phase II” upgrade will enable the subdetectors to sustain the increased luminosity, which results in greater radiation damage and higher particle rates – the innermost pixel layer, for example, will see three billion hits per second per square centimetre. The CMS tracker and the calorimeter endcap will be replaced, a new minimum-ionising-particle precision timing detector (MTD) and a new luminosity detector will be installed, almost all of the existing electronics will be replaced, and additional muon forward stations will be mounted.

High granularity

The key to achieving the necessary HL-LHC performance is to enhance the granularity of the detector significantly. This reduces the maximum occupancy per readout cell while considerably increasing the readout bandwidth and processing power of the trigger system, thereby fully exploiting the higher collision rates. As a novelty, all CMS detector designs are tuned to allow full particle-flow reconstruction at the hardware-based level-1 trigger (operating at 40 MHz), while precision timing information, which contributes to the high-level-trigger decision, is exploited by highly optimised software mostly running on graphics processing units.

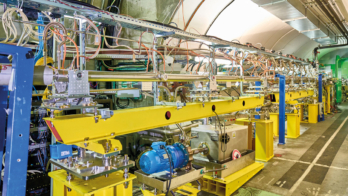

CMS is currently transitioning from the prototyping to the production phase on several major items. The novel gas electron multiplier (GEM) detector concept, used to detect muons produced in the very forward region, was deployed for the first time on a large scale during long shutdown 2 (LS2): 144 chambers in the first station are fully integrated into the ongoing data taking and the second station will be fully installed in a year-end technical stop before LS3 (see “GEM of a detector” image). Finishing endcap-muon upgrades in advance of LS3 allows the collaboration to minimise the repositioning of the CMS disks during LS3 and to reduce its overall duration. In this spirit, CMS has already finished the replacement of all front-end electronics of the cathode strip chambers. The replacement of the drift-tube electronics in the barrel muon detectors will take place in LS3, and an installed small-scale drift-tube demonstrator is already proving its performance.

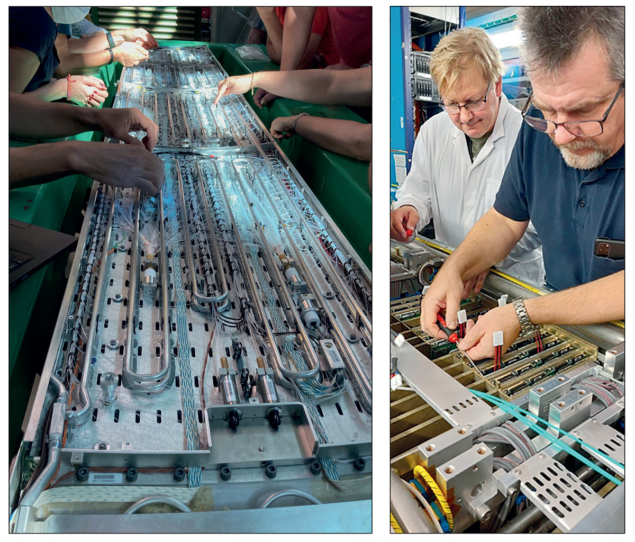

The exceptional performance of the current all-silicon tracker provides a solid platform for even further improvements. A main novelty for Phase II is the level-1 track trigger, which reconstructs tracks with transverse momentum above 2 GeV, made available at a rate of 40 MHz. Profiting from the experience with pixels from Phase I, the whole Phase II tracker will use dual-phase CO2 cooling, ultra-lightweight mechanics, DCDC converters for the powering of the outer tracker, and serial powering for the pixel system, thereby reducing the amount of material by a factor of two compared to today. To reduce the occupancies expected at the highest foreseeable number of collisions per bunch crossing (pile-up), the outer-tracker channel count will increase from 9 million strips to 42 million strips plus 170 million macro-pixels, providing unambiguous z-position measurements. With six barrel layers and five double-disks per endcap, the outer tracker is optimised not only for standalone tracking but also for vertexing, a prerequisite for the track trigger (see “Outer tracker” image).

The outer tracker is already in production, having overcome most engineering and prototyping challenges. ASICs (application-specific integrated circuits) and sensors are being delivered and the order for the hybrids (which host integrated circuits and connections in the front-end modules) has been submitted. The inner tracker (pixel system) will feature two billion micro-pixels, compared to the 125 million at present. Four barrel layers plus 12 disks per endcap enable excellent track seeding and b-quark jet identification over the pseudorapidity range |η| < 4 (much broader than today’s |η| < 2.5). The inner tracker system aspects are understood, sensors will be ordered soon, and teams are waiting for the final readout ASIC to begin module production.

A new era of calorimetry

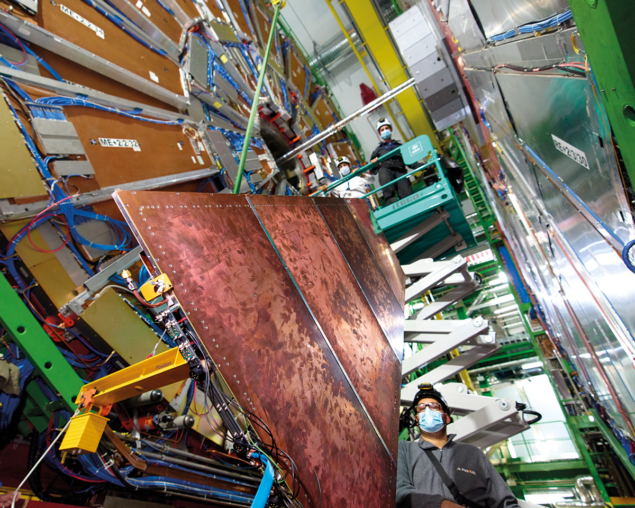

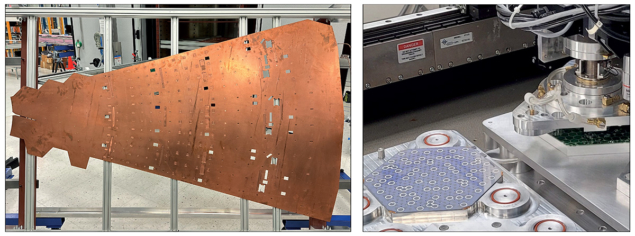

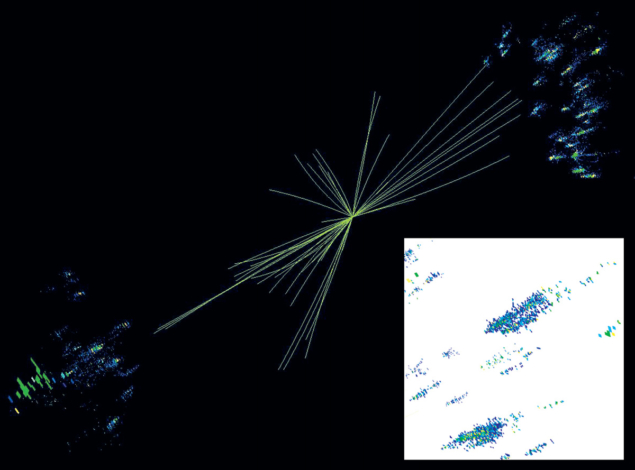

The high-granularity calorimeter (HGCAL) in the forward region starts a new era of calorimetry. It is a radiation-tolerant 5D imaging calorimeter with spatial, energy and precision-timing information (see “HGCAL on display” and “High-granularity calorimetry” images). The deployment of machine-learning algorithms will further enhance its potential to establish the HGCAL as a blueprint for future calorimeters. The HGCAL has 6.4 million channels, two orders of magnitude more than the current endcap calorimeters, including both silicon cells (with an area of 0.5 or 1 cm2) and scintillator tiles (4 to 32 cm2) read out by silicon photomultipliers (SiPMs). The electromagnetic section consists of 26 active layers of silicon sensors interleaved with copper, copper-tungsten and lead absorbers. It is followed by the hadronic section, which is made of 21 active layers of silicon and scintillator tiles, separated by steel absorbers. All in all, 600 m2 are equipped with silicon sensors (three times the area of the tracker) and 400 m2 with SiPMs-on-tiles.

The hexagonal-shaped sensors and the modules mimicking bee-hive structures are a design feature of the HGCAL. The hexagonal structure makes optimal use of the circular silicon wafer, therefore being cost-effective. With the sensor design and evaluation completed, mass production has started. The development of silicon sensors that are sufficiently radiation-tolerant for HL-LHC conditions, for both the HGCAL and the tracker, has taken considerable effort. It is also worth noting the use, for the first time in particle physics, of passive sensors processed on 8-inch wafers – another essential feature for covering larger areas at an affordable cost.

The electromagnetic calorimeter (ECAL) barrel and its 61,200 lead-tungstate crystals, which were instrumental in the discovery of the Higgs boson via its decay to two photons, will be retained and equipped with new front-end electronics capable of sustaining the higher rates and trigger latency (see “ECAL upgrades” image). Faster signal processing will result in a much-improved time resolution of 30 ps for high-energy photons (and electrons), enabling precise primary-vertex determination.

The novel track trigger and the much-improved cell granularity allow the full implementation of the particle-flow reconstruction (based on field-programmable gate arrays, FPGAs) already in the level-1 trigger. The single-crystal granularity that will be provided by the ECAL barrel, even at the trigger level, together with the 3D imaging features of the HGCAL, provide crucial information to precisely follow the path of all particles through the entire detector. This opens the possibility of establishing a full menu of cross-particle triggers and of using FGPA-based machine learning at the level-1 trigger. Trigger algorithms have been prototyped in FPGAs and demonstrated in a multi-board “slice test”. In order to efficiently process the 63 Tb/s input bandwidth, the system is equipped with 250 FPGAs, with an output rate of 750 kHz and a latency of 12.5 μs.

Bright times ahead

For the luminosity measurement, CMS is following a strategy analogous to the one for the trigger, exploiting data from various subdetectors with the ambitious goal of 1% offline (2% online) uncertainty. Achieving this precision requires an understanding of the detector systematic effects, such as linearity and stability, at the per-mille level. A dedicated silicon-pad-based luminometer with an asynchronous readout will help in quantifying systematic uncertainties and beam-related backgrounds, and will play an essential role in the CMS (and LHC accelerator) commissioning.

CMS will enter further uncharted territory in the precision-timing domain with the MTD. For the barrel system, the challenge is to adapt the cost-effective LYSO crystal + SiPM technology, similar to that used in PET scanners, to sustain the HL-LHC rates and radiation. An interesting detail is the use of micro-Peltier elements (thermo-electric coolers) to further decrease the local temperature on the SiPMs, thus counteracting the effects of radiation damage. The endcaps use a new twist on well-established silicon tracking technology: low-gain avalanche detectors, with an additional thin implant within the sensor to generate internal gain. The MTD covers the full solid angle up to |η| = 3 to mitigate pile-up, boost the sensitivity to searches for long-lived particles, and enhance the physics capabilities during heavy-ion runs by providing particle identification capability via time-of-flight measurements.

The high-granularity calorimeter in the forward region starts a new era of calorimetry

All these individual systems are combined into the CMS Phase II detector. Technical coordination is choreographing the integration and has established a detailed schedule for LS3, taking all the detector and external requirements and constraints into account. To maximise the time for detector installation and commissioning during LS3, a huge effort is ongoing in preparing the site in advance. New buildings are already under construction to house the new service infrastructure, such as chillers for the detector CO2 cooling, uninterrupted power systems and detector- and dry-gas systems. During LS3, the biggest challenge will be to decommission all the legacy systems, including services, that will be replaced by new detectors, and then fit all the new pieces together.

The CMS Phase-II upgrade is a multi-faceted project involving more than 2000 scientists, students and engineers from institutes and industrial companies in more than 50 countries. Initially discussed prior to the first LHC operation and defined by the CMS technical proposal in 2015, the CMS Phase II upgrade together with upgrades to the other LHC detectors will ensure that maximal physics is extracted under the challenging conditions of the HL-LHC.

Further reading

CMS Collab. 2015 CERN-LHCC-2015-10.

CMS Collab. 2017 CERN-LHCC-2017-009.

CMS Collab. 2017 CERN-LHCC-2017-011.

CMS Collab. 2017 CERN-LHCC-2017-012.

CMS Collab. 2017 CERN-LHCC-2017-023.

CMS Collab. 2019 CERN-LHCC-2019-003.

CMS Collab. 2020 CERN-LHCC-2020-004.

CMS Collab. 2021 CERN-LHCC-2021-007.

CMS Collab. 2021 CERN-LHCC-2021-008.