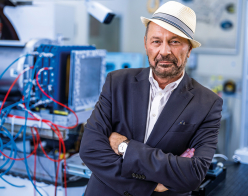

Collaboration with industry is hard-wired into the operational DNA of the German accelerator centre DESY. Djamschid Safi, head of the laboratory’s business development office, explains how big science is helping Europe’s technology and manufacturing companies to fast-track the development of innovative products, services and applications.

Collaboration, applied research services and innovation networks: these are the reference points of an evolving business development strategy that’s building bridges between DESY’s large-scale research infrastructure and end-users across European industry. The goal: to open up the laboratory’s mission in basic science to support technology innovation and, by extension, deliver at-scale economic and societal impact.

As a German national laboratory rooted in physics, and one of the world’s leading accelerator research centres, DESY’s scientific endeavours are organised along four main coordinates: particle physics, photon science, astroparticle physics and the accelerator physics division. Those parallel lines of enquiry, pursued jointly with an established network of regional and international partners, make DESY a magnet for more than 3000 guest scientists from over 40 countries every year.

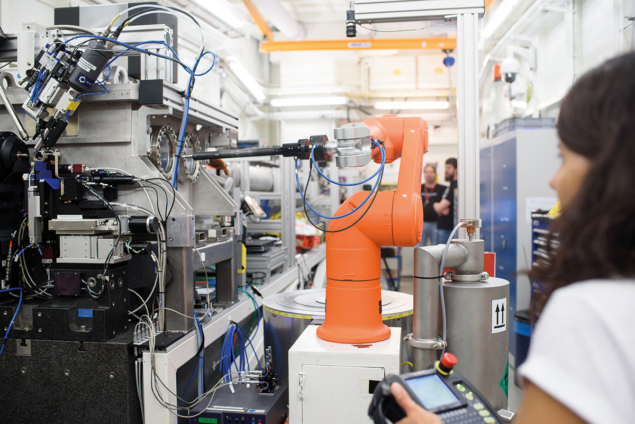

In the same way, the laboratory is a coveted research partner for industry and business, its leading-edge experimental facilities offering a unique addition to the R&D pipeline of Europe’s small and medium-sized enterprises as well as established technology companies.

Technology transfer pathways

Industry collaboration with DESY is nothing if not diverse, spanning applied R&D and innovation initiatives across topics such as compact next-generation accelerator technologies, advanced laser systems for quality control in semiconductor-chip production, and the 3D printing of custom resins to create parts for use in ultrahigh-vacuum environments. While such cooperative efforts often involve established companies from many different industries, partners from academic science play an equally significant role – and typically with start-up or technology transfer ambitions as part of the mix.

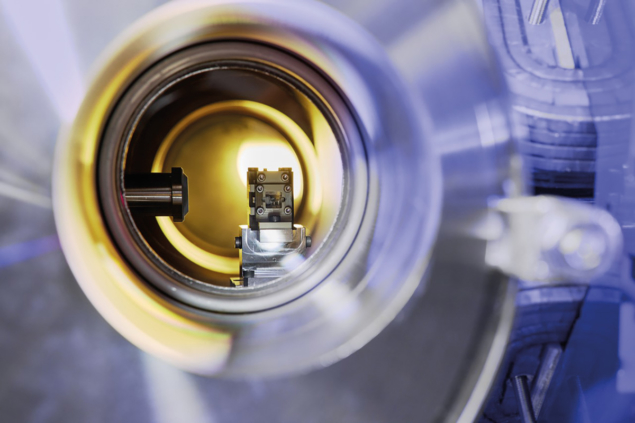

This is the case for an envisaged spin-off project in which scientists from the University of Hamburg and DESY are working together on a portable liquid biopsy device for medical diagnostics applications (for example, in cancer screening and treatment evaluation). Reciprocity is the key to success here: the university researchers bring their background in nanoanalytics to the project, while DESY physicists contribute deep domain knowledge and expertise on the development of advanced detector technologies for particle physics experiments. As a result, a prototype test station for high-sensitivity in-situ analysis is now in the works, with the interaction of the nanochannels and the detector in the test device representing a significant R&D challenge in terms of precision mechanics (while the DESY team also provides expertise in pattern recognition to accelerate the readout of test results).

Elsewhere, DESY’s MicroTCA Technology Lab (TechLab) represents a prominent case study of direct industry collaboration, fostering the uptake of the MicroTCA.4 open electronics standard for applications in research and industry. Originally developed for the telecommunications market, the standard was subsequently adapted by DESY and its network of industrial partners – among them NAT (Germany), Struck (Germany) and CAENels (Italy) – for deployment within particle accelerator control systems (enabling precision measurements of many analogue signals with simultaneous high-performance digital processing in a single controller).

As such, MicroTCA.4 provides a core enabling technology in the control systems of the European X-ray Free Electron Laser (European XFEL), which runs over a 3.4 km span from DESY’s Hamburg location to the main European XFEL campus in the town of Schenefeld. Another bespoke application of the standard is to be found in the ground-based control centre of the Laser Interferometer Space Antenna (LISA), a space-based gravitational wave detector jointly developed by NASA and the European Space Agency.

Underpinning this technology transfer success is a parallel emphasis on knowledge transfer and education. This is the reason why TechLab, which sits as part of the business development office at DESY, offers a programme of annual workshops and seminars for current and prospective users of MicroTCA.4. The long-term vision, moreover, is to develop a commercially self-sustaining TechLab spin-off based on the development and dissemination of MicroTCA into new applications and markets.

Industry services to fast-track innovation

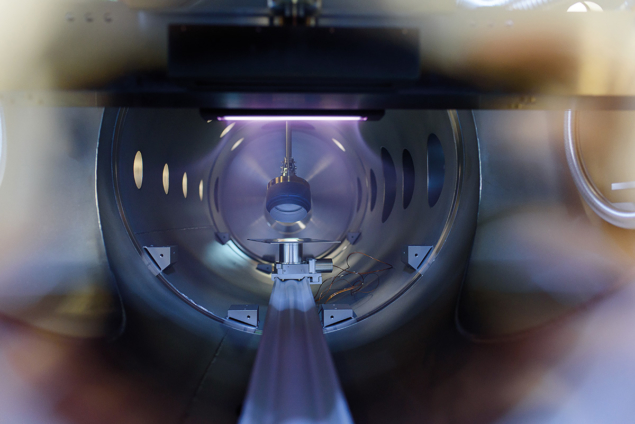

One of the principal drivers of industrial engagement with DESY is the laboratory’s PETRA III synchrotron light source (comprising a 2.3 km-circumference storage ring and 25 experimental beamlines). This high-brilliance X-ray facility is exploited by academic and industrial scientists to shed light on the structure and behaviour of matter at the atomic and molecular level across a range of disciplines – from clean-energy technologies to drug development and healthcare, from structural biology and nanotech to food and agricultural sciences.

DESY photon scientists and engineers ensure that industrial users are in a position to maximise the return on their PETRA III beam time

Operationally, DESY photon scientists and engineers ensure that industrial users are in a position to maximise the return on their PETRA III beam time, offering a portfolio of services that includes feasibility studies, sample preparation, execution of measurements, as well as downstream analysis of experimental data. Industry customers can request proprietary access to PETRA III via the business development office (under a non-disclosure agreement if necessary), while clients do not even need to come to DESY themselves, with options for a mail-in sample service or even remote access studies in certain circumstances. Publication is not required under this access model, though discounted fees are available to industry users willing to publish a “success story” or scientific paper in partnership with DESY.

Alongside the proprietary route, companies are able to access PETRA III beam time through academic partners. This pathway is free of charge and based on research proposals with strong scientific or socioeconomic impact (established via a competitive review process), with a requirement that results are subsequently published in the formal scientific literature. Notwithstanding the possibilities offered by DESY itself, the laboratory’s on-campus partners – namely the Helmholtz Centre Hereon and the European Molecular Biology Laboratory (EMBL) – use PETRA III to deliver a suite of dedicated services that help industry customers address diverse problems in the applied R&D pipeline.

The German biotech company BioNTech is a case in point. Best known for its successful mRNA vaccine against SARS-Cov-2 infections, BioNTech conducted a programme of X-ray scattering experiments at EMBL’s PETRA III beamline P12. The results of these investigations are now helping the company’s scientists to better package mRNA within nanoparticles for experimental vaccines and drugs. Along an altogether different R&D track, PETRA III has helped industry users gain novel insights into the inner life of conventional AAA batteries – studies that could ultimately lead to products with significantly extended lifetimes. Using non-invasive X-ray diffraction computer tomography, applied under time-resolved conditions, the studies revealed aspects of the battery ageing process by examining phase transformations in the electrodes and electrolyte during charging and discharge.

Building an innovation ecosystem

While access to DESY’s front-line experimental facilities represents a game-changer for many industry customers, the realisation of new commercial products and technologies does not happen in a vacuum. Innovators, for their part, need specialist resources and expert networks to bring their ideas to life – whether that’s in the form of direct investment, strategic consultancy, business and entrepreneurship education, or access to state-of-the-art laboratories and workshops for prototyping, testing, metrology and early-stage product qualification.

DESY is single-minded in its support for this wider “innovation ecosystem”, with a range of complementary initiatives to encourage knowledge exchange and collaboration among early-career scientists, entrepreneurs and senior managers and engineers in established technology companies. The DESY Start-up Office, for example, offers new technology businesses access to a range of services, including management consultancy, business plan development and networking opportunities with potential suppliers and customers. There’s also the Start-up Labs Bahrenfeld, an innovation centre and technology incubator on the DESY Hamburg campus that provides laboratory and office space to young technology companies. The incubator’s current portfolio of 16 start-ups reflects DESY’s pre-eminence in lasers, detectors and enabling photonic technologies, with seven of the companies also targeting applications in the life sciences.

A more focused initiative is the CAROTS 2.0 Startup School, which provides scientists with the core competencies for running their own scientific service companies (intermediary providers of analytical research services to help industry make greater use of large-scale science facilities like DESY). Longer term, the DESY Innovation Factory is set to open in 2025, creating an ambitious vehicle for the commercial development of novel ideas in advanced materials and the life sciences, while fostering cooperation between the research community and technology companies in various growth phases. There will be two locations, one on the DESY campus and one in the nearby innovation and technology park Vorhornweg.

Basic science, applied opportunities

If the network effects of DESY’s innovation ecosystem are a key enabler of technology transfer and industry engagement, so too is the relentless evolution of the laboratory’s accelerator R&D programme. Consider the rapid advances in compact plasma-based accelerators, offering field strengths in the GV/m regime and the prospect of a paradigm shift to a new generation of user-friendly particle accelerators – even potentially “bringing the accelerator to the problem” for specific applications. With a dedicated team working on the miniaturisation of particle accelerators, DESY is intent on maturing plasma technologies for its core areas of expertise in particle physics and photon science while simultaneously targeting medical and industrial use-cases from the outset.

Meanwhile, plans are taking shape for PETRA IV and conversion of the PETRA storage ring into an ultralow-emittance synchrotron source. By generating beams of hard X-rays with unprecedented coherence properties that can be focused down to the nm regime, PETRA IV will provide scientists and engineers with the ultimate 3D process microscope for all manner of industry-relevant problems – whether that’s addressing individual organelles in living cells, following metabolic pathways with elemental and molecular specificity, or observing correlations in functional materials over mm length scales and under working conditions.

Fundamental science never stops at DESY. Neither, it seems, do the downstream opportunities for industrial collaboration and technology innovation.