The reliability of the LHC cryogenics system has been central to the collider’s successful operation and provision of high integrated luminosity.

The LHC is one of the coldest places on Earth, with superconducting magnets – the key defining feature – that operate at 1.9 K. While there might be colder places in other laboratories, none compares to the LHC’s scale and complexity. The cryogenic system that provides the cooling for the superconducting magnets, with their total cold mass of 36,000 tonnes, is the largest and most advanced of its kind. It has been running continuously at some level since January 2007, providing stalwart service and achieving an availability equivalent to more than 99% per cryogenic plant.

The task of keeping the 27-km-long collider at 1.9 K is performed by helium that is cooled to its superfluid state in a huge refrigeration system. While the niobium-titanium alloy in the magnet coils would be superconducting if normal liquid helium were used as the coolant, the performance of the magnets is greatly enhanced by lowering their operating temperature and by taking advantage of the unique properties of superfluid helium. At atmospheric pressure, helium gas liquefies at around 4.2 K but on further cooling it undergoes a second phase change at about 2.17 K and becomes a superfluid. Among many remarkable properties, superfluid helium has a high thermal conductivity, which makes it the coolant of choice for the refrigeration and stabilization of large superconducting systems.

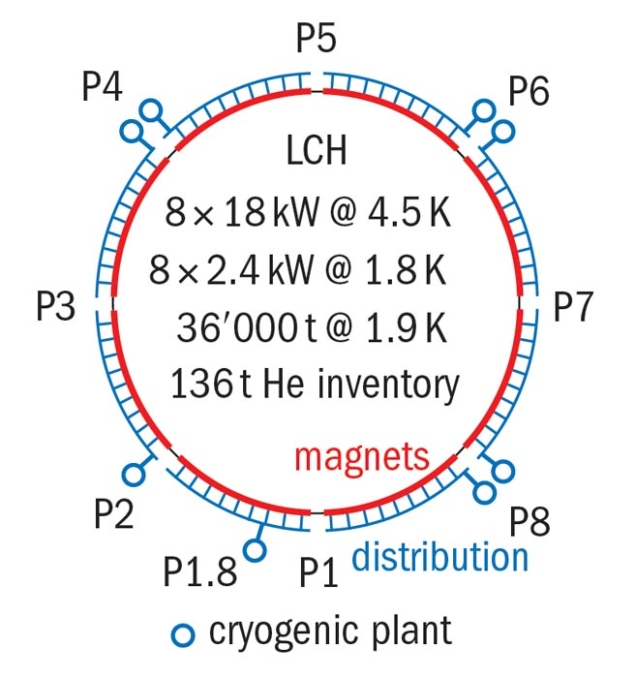

The LHC consists of eight 3.3-km-long sectors with sites for access shafts to services on the surface at the ends of each sector. Five of these sites are used to locate the eight separate cryogenic plants, each dedicated to serving one sector (figure 1). An individual cryoplant consists of a pair of refrigeration units: one, the 4.5 K refrigerator, provides a cooling-capacity equivalent to 18 kW at 4.5 K; while the other, the 1.8 K refrigeration unit, provides a further cooling capacity of 2.4 kW at 1.8 K. Therefore, each of the eight cryoplants must distribute and recover kilowatts of refrigeration across a distance of 3.3 km, to be achieved with a temperature change of less than 0.1 K.

Four of the 4.5 K refrigerators were recovered from the second phase of the Large Electron–Positron collider

Four of the 4.5 K refrigerators were recovered from the second phase of the Large Electron–Positron collider (LEP2), where they were used to cool its superconducting radiofrequency cavities. These “recycled” units have been upgraded to operate on the LHC sectors that have a lower demand for refrigeration. The four high-load sectors are instead cooled by new 4.5 K refrigerators. The refrigeration capacity needed to cool the 4500 tonnes of material in each sector of the LHC is enormous and can be produced only by using liquid nitrogen. Consequently, each 4.5 K refrigerator is equipped with a 600-kW liquid-nitrogen pre-cooler. This is used to cool a flow of helium down to 80 K while the corresponding sector is cooled before being filled with helium – a procedure that takes just under a month. Using only helium in the tunnel considerably reduces the risk of oxygen deficiency in the case of an accidental release.

The 4.5 K refrigeration system works by first compressing the helium gas and then allowing it to expand. During expansion it cools by losing energy through mechanical turbo-expanders that run at up to 140,000 rpm on helium-gas bearings. Each of the refrigerators consists of a helium-compressor station equipped with systems to remove oil and water, as well as a vacuum-insulated cold box (60 tonnes) where the helium is cooled, purified and liquefied. The compressor station supplies compressed helium gas at 20 bar and room temperature. The cold box houses the heat exchangers and turbo-expanders that provide the cooling capacities necessary to liquefy the helium at 4.5 K. The liquid helium then passes to the 1.8 K refrigeration unit, where the cold-compressor train decreases its saturation pressure and consequently its saturation temperature down to 1.8 K. Each cryoplant is equipped with a fully automatic process-control system that manages about 1000 inlets and outlets per plant. The system takes a total electrical input power of 32 MW and reaches an equivalent cooling capacity of 144 kW at 4.5 K – enough to provide almost 40,000 litres of liquid helium per hour.

In the LHC tunnel, a cryogenic distribution line runs alongside the machine. It consists of eight continuous cryostats, each about 3.2 km long and housing four (or five) headers to supply and recover helium, with temperatures ranging from 4 K to 75 K. A total of 310 service modules, of 44 different types feed the machine. These contain sub-cooling heat exchangers, all of the cryogenic control valves for the local cooling loops and 1–2 cold pressure-relief valves that protect the magnet cold masses, as well as monitoring and control instrumentation. Overall, the LHC cryogenic system contains about 60,000 inlets and outlets, which are managed by 120 industrial-process logic controllers that implement more than 4000 PID control loops.

Operational aspects

The structure of the group involved with the operation of the LHC’s cryogenics has evolved naturally since the installation phase, so maintaining experience and expertise. Each cryogenically independent sector of the LHC and its pair of refrigerators is managed by its own dedicated team for process control and operational procedures. In addition, there are three support teams for mechanics, electricity-instrumentation controls and metrology instrumentation. A further team handles scheduling, maintenance and logistics, including cryogen distribution. Continuous monitoring and technical support is provided by personnel who are on shift “24/7” in the CERN Control Centre and on standby duties. This constant supervision is necessary because any loss of availability for the cryogenic system impacts directly on the availability of the accelerator. Furthermore, the response to cryogenic failures must be rapid to mitigate the consequences of loss of cooling.

In developing a strategy for operating the LHC it was necessary to define the overall availability criteria. Rather than using every temperature sensor or liquid-helium level as a separate interlock to the magnet powering and therefore the beam permit, it made more sense to organize the information according to the modularity of the magnet-powering system. As a result, each magnet-powering subsector is attributed a pair of cryogenic signals: “cryo-maintain” (CM) and “cryo-start” (CS). The CM signal corresponds to any condition that requires a slow discharge of the magnets concerned, while the CS signal has more stringent conditions to enable powering to take place with sufficient margins for a smooth transition to the CM threshold. A global CM signal is defined as the combination of all of the required conditions for the eight sectors. This determines the overall availability of the LHC cryogenics.

During the first LHC beams in 2009, the system immediately delivered availability of 90% despite there being no means of dealing quickly with identified faults. These were corrected whenever possible during the routine technical stops of the accelerator and the end-of-year stops. The main issues resolved during this phase were the elimination of two air leaks in sub-atmospheric circuits, the consolidation of all of the 1200 cooling valves for current leads and the 1200 electronic cards for temperature sensors that were particularly affected by energetic neutron impacts, so-called single-event upsets (SEUs).

Since early operation for physics began in November 2009, the availability has been above 90% for more than 260 days per year. A substantial improvement occurred in 2012–2013 because of progress in the operation of the cryogenic system. The operation team undertook appropriate training that included the evaluation and optimization of operation settings. There were major improvements in handling utilities-induced failures. In particular, in the case of electrical-network glitches, fine-tuning the tolerance thresholds for the helium compressors and cooling-water stations represented half of the gain. A reduction in the time taken to recover nominal cryogenic conditions after failures also led to improved availability. The progress made during the past three years led to a reduction in the number of short stops, i.e. less than eight hours, from 140 to 81 per year. By 2012, the efforts of the operation and support teams had resulted in a global availability of 94.8%, corresponding to an equivalent availability of more than 99.3% for each of the eight cryogenically independent sectors.

In addition, the requirement to undertake an energy-saving programme contributed significantly to the improved availability and efficiency of the cryogenic system – and resulted in a direct saving of SwFr3 million a year. Efforts to improve efficiency have also focused on the consumption of helium. The overall LHC inventory comes to 136 tonnes of helium, with an additional 15 tonnes held as strategic storage to cope with urgent situations during operation. For 2010 and 2011, the overall losses remained high because of increased losses from the newly commissioned storage tanks during the first end-of-year technical stop. However, the operational losses were substantially reduced in 2011. Then, in 2012, the combination of a massive campaign to localize all detectable leaks – combined with the reduced operational losses – led to a dramatic improvement in the overall figure, nearly halving the losses.

Towards the next run

Thanks to the early consolidation work already performed while ramping up the LHC luminosity, no significant changes are being implemented to the cryogenic system during the first long shutdown (LS1) of the LHC. However, because it has been operating continuously since 2007, a full preventive-maintenance plan is taking place. A major overhaul of helium compressors and motors is being undertaken at the manufacturers’ premises. The acquisition of important spares for critical rotating machinery is already completed. Specific electronic units will be upgraded or relocated to cope with future radiation levels. In addition, identified leaks in the system must be repaired. The consolidation of the magnet interconnections – including the interface with the current leads – together with relocation of electronics to limit SEUs, will require a complete re-commissioning effort before cool-down for the next run.

The scheduled consolidation work – together with lessons learnt from the operational experience so far – will be key factors for the cryogenic system to maintain its high level of performance under future conditions at the LHC. The successful systematic approach to operations will continue when the LHC restarts at close to nominal beam energy and intensity. With greater heat loads corresponding to increased beam parameters and magnet currents, expectations are high that the cryogenic system will meet the challenge.