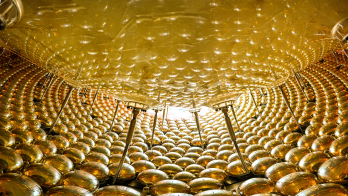

Giant superconducting magnets for experiments are one of a kind.

Image credit: M Brice, B Michel/CERN.

To identify particles emerging from high-energy interactions between a beam and a fixed target, or between two counter-rotating beams, experimental physicists need to measure the particle tracks with high precision. Since charged particles are deflected in a magnetic field, incorporating a magnet in the detector system serves to determine both the charge and momentum of a particle. Momentum resolution is proportional to the sagitta of the detected track, which is proportional to the magnetic field and the square of the length of the track, so larger magnets and larger fields tend to deliver better performance. While being as large and as strong as possible, however, the magnet should not get in the way of the active detector materials.

These general constraints in high-energy physics experiments point to a need for more compact superconducting devices. But additional constraints such as cost, complexity and experiment schedules can lead to the choice of a conventional “warm” magnet if sufficient field and volume can be provided for acceptable power consumption. A detector magnet is one of a kind, and a field accuracy of one part in 1000 is usually sufficient. In contrast, accelerator magnets are typically many of a kind, and are required to deliver the highest possible field with an accuracy of one part in 10,000 or better in a long and narrow aperture. This leads to substantially different technological choices.

Following the discovery of superconductivity, people immediately thought of using it to produce magnetic fields. But the pure materials concerned (later to be called type-I superconductors) only worked up to a critical field of about 0.1 T. The discovery in 1961 of more practical (type-II) superconductivity in certain alloys and compounds which, unlike type-I, allow penetration of magnetic flux but exhibit critical fields of 10–20 T, immediately led to renewed interest. Physics laboratories in Europe and the US started R&D programmes to understand how to make superconducting magnets and to explore possible applications.

The first four years were difficult: small magnets were built but it was not possible to get scaled-up versions to operate at currents anywhere close to the level obtained for short samples of the superconducting wire available at the time. A breakthrough was presented at the first Particle Accelerator Conference in 1965, in a seminal paper by Steckly and Zar on cryogenic stability. Cryogenic stability ensures that, if a superconductor becomes normal due to coil motion or a flux jump (when magnetic flux penetrates a thick type-II material leading to instability, resistance and increased temperature), it will recover its superconductivity provided enough heat can be conducted away to the coolant for the material to drop back below its critical temperature in the region where superconductivity was lost. Several laboratories immediately started to build large helium-bath-cooled bubble-chamber magnets.

The bubble chamber, invented by Donald Glaser in 1952, consists of a tank of liquid hydrogen surrounded by a pair of Helmholtz coils: particles leave tracks in the supercritical liquid and their curvatures reveal the particle’s momentum. The first large (72 inch) bubble-chamber magnet at the University of California Radiation Laboratory was equipped with a 1.8 T water-cooled copper coil weighing 20 tonnes and dissipating a power of 2.5 MW. Larger magnets were desirable for improved resolution, but were clearly unrealistic with room-temperature copper coils due to the costs involved. This was therefore an obvious application for superconductivity, and the concept of cryogenic stability allowed large magnets to be built using a superconductor that was otherwise inherently unstable.

Recall that this was before seminal work at the Rutherford Appleton Laboratory (RAL) had revealed the need for fine filaments and twisting to ensure stability, and before we knew that practical superconductors had to be made in that way. Indeed, it is striking to observe the audacity of high-energy physicists in the late 1960s and the early 1970s in embarking on the construction of such large and costly devices so rapidly, based on so little experience and knowledge.

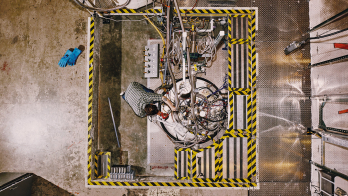

Image credits: M Brice; C Marcelloni.

Thick filaments of niobium-titanium in a copper matrix were the superconducting material of choice at the time, with coils being cooled in a bath of liquid helium. Achievements included: the 1.8 T magnet at Argonne National Laboratory for its bubble-chamber facility; a 3 T magnet for a facility at Fermilab; and the 3.5 T Big European Bubble Chamber (BEBC) magnet at CERN. The stored energy of the BEBC magnet was almost 800 MJ – a level not exceeded for a large magnet until the Large Helical Device came on stream in Japan (for fusion experiments) in the late 1990s. This use of superconducting magnets for experiments preceded by several years their practical application to accelerators.

Discoveries

Following early experiments at CERN’s Intersecting Storage Rings, which were not well equipped to observe particles having large transverse momentum, the importance of detecting all of the particles produced in beam collisions in colliders was recognised, and a need emerged for magnets covering close to a full 4π solid angle. To improve momentum resolution it was also desirable to extend the measurement of tracks beyond the magnet winding, calling for thin coils. The goal was less than one radiation length in thickness, for which a high-performance superconductor with intrinsic stability was needed. This pointed towards a design based on the type of superconducting wire that had been developed in the accelerator community and had by now become a commodity for making MRI magnets (an industry that now consumes more than 90% of the superconductors produced), with the attendant reduction in cost.

Therefore by the early 1980s the development of detector magnets had shifted to conductors made of by then standard superconducting wires consisting of twisted fine filaments in a copper matrix, single or cabled, co-extruded with ultra-pure aluminium to provide stabilization, and wound in solenoidal coils inside a hard aluminium alloy mandrel for support. Pure aluminium is an excellent conductor at low temperature, and far more transparent than the copper that had been used previously. Moreover, rather than being bath cooled, these constant field magnets were indirectly cooled to about 5 K with helium flowing in pipes in good thermal contact with the mandrel. This allowed the 1–2 T detector solenoids to become larger, without power dissipation in the winding and with a low inventory of liquid helium. In this way the coils can be made thin and relatively transparent to certain classes of particles such as muons, so that detectors can be located both inside and outside. Examples of these magnets are those used for the ALEPH and DELPHI experiments at CERN’s Large Electron–Positron (LEP) collider, the D0 experiment at Fermilab and the BELLE experiment at KEK. Other prominent experiments over the years based on superconducting magnets include VENUS at KEK, ZEUS at DESY, and BaBAR at SLAC.

To the Higgs boson and beyond

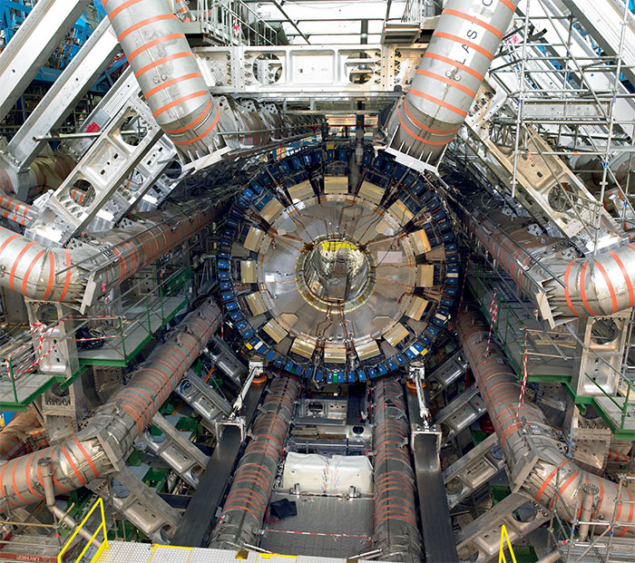

While this had become the standard approach to detector magnet design, the magnets in the ATLAS and CMS experiments at the LHC occupy new territory. ATLAS uses a large toroidal coil structure surrounding a thin 2 T solenoid, and the solenoid for CMS delivers an unprecedented 3.8 T (but is not required to be very thin). While both the CMS and ATLAS solenoids use the now traditional technology based on niobium-titanium superconductor co-extruded in aluminium, to allow the structure to withstand the substantial forces the pure aluminium stabiliser is reinforced. This is done either by welding aluminium-alloy flanges to the pure aluminium (CMS) or by strengthening the pure aluminium with a precipitate that improves its strength while not increasing inordinately the resistivity of the aluminium (ATLAS solenoid).

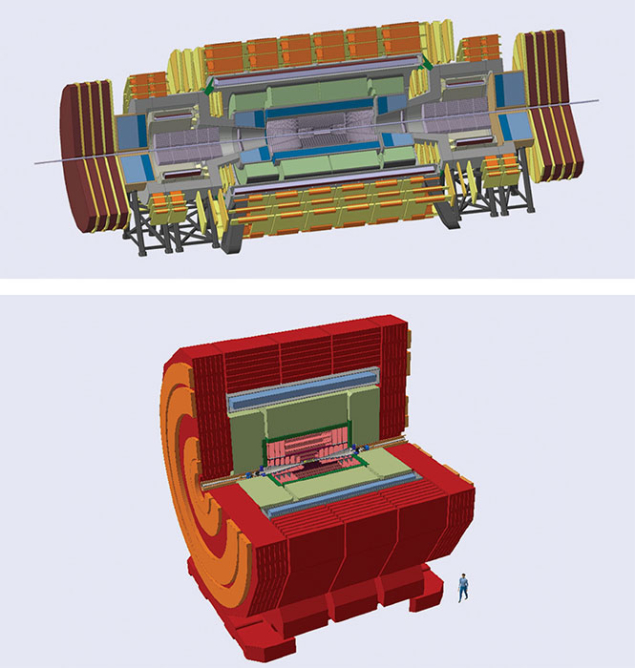

The next generation of magnets planned for the Compact Linear Collider (CLIC), the International Linear Collider (ILC) and Future Circular Colliders (FCC) will be larger, and may require more technological development to reach the desired magnetic fields. Based on a single detector at the interaction point, a new unified detector model has been developed for CLIC and the concepts explored for this detector are also of interest to the high-luminosity, as well as for a future circular electron–positron collider. Like the LHC with ATLAS and CMS, a future circular collider requires a “general-purpose” detector. Previous studies for a detector for a 100 TeV circular hadron collider were based on a twin solenoid paired with two forward dipoles, but these have now been dropped in favour of a simpler system comprising one main solenoid enclosed by an active shielding coil. This design achieves a similar performance while being much lighter and more compact, resulting in a significant scaling down in the stored energy of the magnet from 65 GJ to 11 GJ. The total diameter of the magnet is around 18 m, and the new design could benefit from the important lessons from the construction and installation of the LHC detectors.

Key to the choice of such magnets, in addition to their cost and complexity, is their ability to allow high-quality muon tracking. This is crucial for studying the properties of the Higgs boson, for example, and any additional new fundamental particles that await discovery. If the lengthy discussions surrounding the design of the ATLAS and CMS magnets many years ago are anything to go by we can look forward to intense and interesting debates about how to push these one-off magnet designs to the next level.