A new tungsten monocrystalline positron target has generated an intense positron beam at the injector linac of the KEK B-factory (KEKB). It has operated stably since its first use in September 2006 and it is helping to increase the integrated luminosity of KEKB. Crystal positron sources of this kind could be important for the next generation of B-factories and electron–positron linear colliders.

The new positron target at KEKB consists of a 5 mm square tungsten monocrystal 10.5 mm thick, which is bombarded with 4 GeV electrons. The positrons created are then collected and accelerated in succeeding sections up to the final energy of 3.5 GeV for injection into the KEKB positron ring. A conventional target of a 14 mm thick tungsten plate has previously been used, giving a conversion efficiency – the ratio of the number of positrons captured in the positron-capture section and the number of the incident electrons (Ne+⁄Ne–) – of 0.20 (mean). Replacing the tungsten plate with the tungsten crystal has increased the conversion efficiency to 0.25 (mean) (figure 1), which in turn has boosted the positron intensity to its highest since KEKB began operating in 1999.

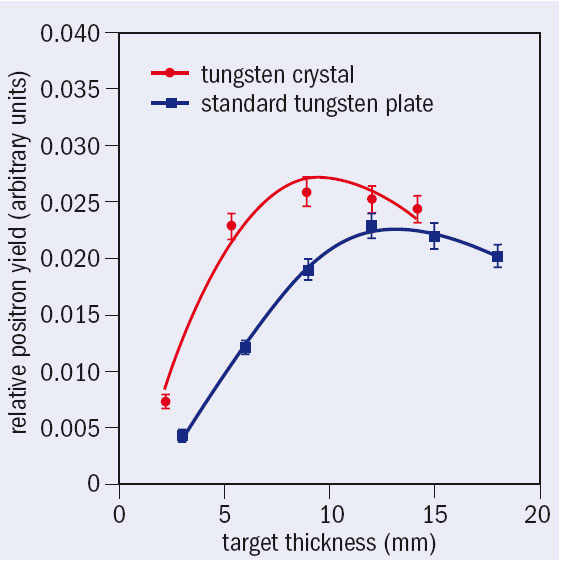

In a positron source, electrons radiate photons when they interact in a suitable target, and the photons then create electron–positron pairs. The use of a crystal target as a good alternative positron source was first proposed by Robert Chehab and colleagues at Laboratoire de l’Accélérateur Linéaire (LAL), Orsay, in 1989. The method has the advantage of producing high photon intensities by channelling radiation and coherent bremsstrahlung. Experiments at CERN (WA103) and KEK confirmed that the positron yield from a crystal target is remarkably enhanced at higher electron energies. Studies have since been done at KEK to find the optimum crystal thickness as a function of the incident electron energy (figure 2), and Tomsk Polytechnic University has developed tungsten crystals of various thicknesses.

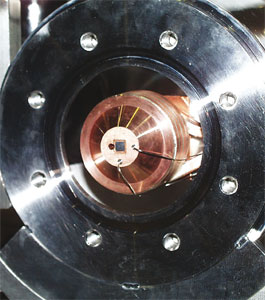

Technology for mounting the tungsten crystal in the positron production station at KEK has also been studied carefully because the <111> crystal axis must be oriented with respect to the direction of the incident electrons to within 1 mrad. To achieve this precise orientation without alignment devices, the target assembly (figure 3) was carefully fabricated, using X-ray Bragg-reflection measurements to ensure that the crystal axis orientation was correct. The team then installed the crystal target at the operational positron source of the KEKB injector linac, and it has since been operating stably. Continued operation at KEKB will provide useful information about radiation damage and the stability of the crystal target.

• This work has been done through the collaborative efforts of Tokyo Metropolitan University, Kyushu Synchrotron Light Research Center, Tomsk Polytechnic University, LAL and KEK.