A silicon strip detector is providing more power for particle detection in Brookhaven National Laboratory’s STAR experiment.

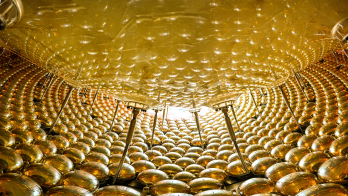

An important milestone has been reached in the STAR experiment at Brookhaven’s Relativistic Heavy Ion Collider (RHIC) with the integration of the silicon strip detector (SSD). The installation completes the STAR ensemble, which is dedicated to tracking the thousands of charged particles that emerge at large angles to the colliding beams. The SSD has been fully commissioned and is now collecting data.

The completion of the STAR SSD is the result of a multi-year French research and development effort that began shortly after STAR started taking data in 2000, and which was led by the Laboratoire de Physique Subatomique et des Technologies Associées (Subatech) in Nantes, and the Institut de Recherche Subatomique (IreS) in Strasbourg. The detector incorporates state-of-the-art bonding technology as well as front-end electronics and control chips designed and developed by the Laboratoire d’Electronique et de Physique des Systèmes Instrumentaux (LEPSI) in Strasbourg.

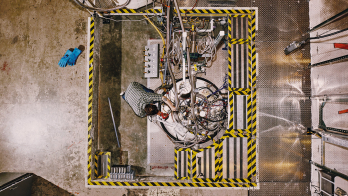

The SSD makes extensive use of double-sided silicon microstrip sensors and has a total sensitive area of about 1 square metre. The detector consists of 320 detector modules arranged on 20 ladders (see figures 1 and 2). These form a barrel at a radius of 23 cm from the beam, inserted between the silicon vertex tracker (SVT) and the time projection chamber (TPC).

The detector enhances the tracking capabilities of the STAR experiment in this region by providing information on the positions of hits and on the ionization energy loss of charged particles. Specifically, the SSD improves the extrapolation of tracks in the TPC to the hits found in the SVT. This increases the average number of space points measured near the collision vertex, significantly improving the detection efficiency for long-lived meta-stable particles such as those found in hyperon decays. Moreover, the SSD will further enhance the SVT tracking capabilities for particles with very low momentum, which do not reach the TPC.

The SSD was based on an early proposal for the Inner Tracking System of the ALICE experiment at CERN’s Large Hadron Collider; however, the design of the detector has evolved and matured considerably after several years of research, development and prototyping. To fulfil the constraints of the STAR environment, innovative solutions were required for electronics, connections and mechanics.

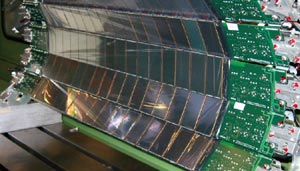

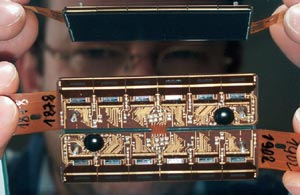

The detector module comprises one double-sided silicon microstrip sensor and floating electronics on two hybrid circuits of very low mass (see figure 3). The silicon sensor contains 1536 analogue channels (768 x 2) and has a resolution of 17 μm in azimuth (Rφ) and 700 μm in the beam direction (z). Each of the hybrid circuits is dedicated to one side of the sensor and hosts six A128C front-end chips and a Costar chip for control purposes. The hybrids are connected to the outer boards via a low-mass Kapton-aluminium bus, manufactured at CERN.

The A128C front-end chip, developed in a collaboration between LEPSI and IReS, shows an extended input range corresponding to ±13 MIPs (minimum ionizing particles) and an extra-low power consumption of less than 350 μW per channel. A dedicated multipurpose application-specific integrated circuit is in charge of the hybrid controls and temperature measurements.

Kapton-copper microcables and state-of-the-art tape automated bonding (TAB) technology connect the silicon readout strips to the input channels of the front-end electronics chip, and the chips to their hybrids. TAB enables a flexible connection, which acts as an adapter between the different pitches of the detectors and the chips. The technology is also testable and it provided a good yield during production. It was essential to make the detector modules small enough to be integrated into STAR.

Another unique feature of the SSD is its air-cooling system

Another unique feature of the SSD is its air-cooling system. The carbon-fibre-based structure on the ladder that supports the detector modules, analogue-to-digital converters, and control boards is wrapped with a Mylar foil and defines a path to guide the flow of air induced by transvector airflow amplifiers. This design avoids the use of liquid coolant, cooling pipes and heat bridges, and provides a material budget with a total radiation length very close to 1%.

A high level of serialization has been reached by incorporating the analogue-to-digital converters and control boards close to the detector modules. This enables the data from the half million channels of the SSD to be transported to the STAR data acquisition system using only four giga-link optical fibres. In the future, additional parallelization of the readout will enable the readout speed of the SSD to be increased to match the trigger and data-taking rates foreseen for STAR in the high-luminosity era of RHIC II.

The SSD project has been funded by the IN2P3/CNRS, the Ecole des Mines de Nantes, the metropolitan district of Nantes, the Loire-Atlantique department, and the regions of Alsace and Pays de la Loire. Financial support has also been provided by the US Department of Energy through the STAR collaboration.

Further reading

L Arnold et al. 2003 Nucl. Instr. Meth. A499 652.

See also the SSD Web site: http://star.in2p3.fr.