The countdown to the LHC start-up has begun, but even before the first protons have collided, pixel detectors designed for the CMS experiment are being used in other areas.

When the CMS experiment begins recording data at the LHC the first components to detect particles produced in the head-on proton–proton collisions will be those in the layers of silicon pixels that form the inner part of the CMS tracker (figure 1). The pixel detectors in the barrel part of the cylindrical tracker are the responsibility of a Swiss collaboration based at the Paul Scherrer Institute (PSI). These specially developed detectors have to fulfil extreme requirements. In addition, their high performance in tests has resulted in similarly designed but simpler detectors for investigations into protein crystallography at the Swiss Light Source and radiography at the Swiss Spallation Neutron Source. These detectors are already in operation and a start-up company has been formed to supply them to other synchrotron light sources.

Researchers at PSI began developing a hybrid pixel detector system 12 years ago that would be suitable for the very high rates of particle tracks expected at the LHC. Roland Horisberger, project manager of the pixel project, recalls that at the time such a pixel system appeared very futuristic and posed many questions. Nevertheless, researchers from PSI, the universities of Basel and Zurich, and the ETH Zurich gathered together and formed a pixel competence centre to develop a pixel vertex detector for CMS.

Pixels at work

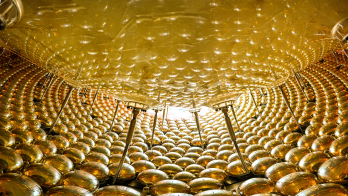

This new detector is in essence a very large digital camera for recording the tracks of ionizing particles. It comprises 65 million silicon pixels, each 100 μm × 150 μm, which are micro-bump-bonded to special complementary metal-oxide semiconductor (CMOS) read-out chips. This enables researchers to record precisely the position and time of a penetrating particle track. The read-out chip detects the hit pixels and records their analogue pulse height. It is then possible, using charge division, to achieve an excellent position resolution of 10–15 μm, while limiting the data transfer to the hit pixels only. For this purpose each pixel is equipped with a fast charge-sensitive amplifier with an analogue sample-and-hold circuit and a discriminating comparator circuit to perform the hit “decision”.

The pixel barrels contain as many as 768 silicon sensor modules, each of which has a sensitive area of about 10 cm2 and consists of a matrix of 160 pixels × 416 pixels. The charge produced by the 66,560 pixels is conducted through an equal number of micro-bump-bonded contacts to 16 read-out chips, each containing 4160 cells, where the charge signals are amplified and processed.

These “hybrid” pixel detectors depend on a special high-density connection technique, which was developed in co-operation with the Laboratory for Micro- and Nanotechnology at PSI. The contact between pixel and microchip – the bump – is a 17 μm solder ball of indium, a metal with a low melting point. The technique, known as bump-bonding, was taken from industry and miniaturized further to achieve the desired small bump ball size (figure 2). The work requires that the bump-bonding is achieved with a precision of 1–2 μm.

At CMS the pixel modules are placed close to the beam pipe at radii of 4, 7 and 11 cm. They provide the three innermost charged-particle tracking points of the experiment and should enable the reconstruction of the secondary displaced vertices arising from b-quark decays, a crucial signature for the discovery of new physics processes. At the design luminosity of the LHC the enormous particle flux of nearly 1010 particles per second will create 120 GB of data every second. The intensive bombardment creates an extreme radiation load on the detectors and the associated on-board electronics. Yet tests at the PSI proton accelerator have shown that this does not significantly affect the functioning of the detectors.

From the LHC to protein crystals

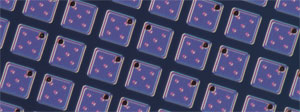

The detector technology developed for CERN measures particle tracks for high-energy particle physics, but at the Swiss Light Source the same technology operates as a very sensitive digital X-ray camera known as the PILATUS 6M detector (for “Pixel Apparatus for the SLS”; figure 3). It consists of 60 modules with 6 million pixels, making up an active area of 43 cm × 45 cm. Adapted to the needs of experiments at synchrotrons, the detector operates in single-photon counting mode – each incoming photon is counted and the number for each pixel is stored digitally.

The process has no electrical background interference, so it achieves an extremely high dynamic range. Very weak and very intense signals can therefore be measured at the same time in a single image, and exposure times can be selected freely between 1 ms and several hours. The CMOS chips and the sensors are radiation tolerant, and the PILATUS 6M detectors have a dynamic range of 20 bits, a highest sensitivity in the energy range of 3–30 keV and a read-out time of a few milliseconds.

When this equipment was being developed the focus was on its application for protein crystallography. Understanding the molecular structure of a crystal requires knowing the intensities of all the reflections as accurately as possible. Researchers can use this information to calculate the actual arrangement of the atoms and molecules in the protein, but the quality of data used to decode the molecular structure is crucial.

In these experiments the researchers fire a tightly bundled X-ray beam onto a protein crystal. This results in images that are patterns formed by thousands of scattered Bragg reflections. The advantage of pixel detectors is that they can deal with the incoming data in the most efficient way. The rate of more than 1 million X-ray photons per second hitting just a few pixels means that the reflections at the centre of the image are extremely intense; at large scattering angles towards the edge there are far fewer reflections from a few dozen photons. Molecular biologists are excited about the excellent data quality they have obtained so far with the PILATUS 6M detector.

The PILATUS 100K detector is a smaller system that was developed in parallel. This system consists of a matrix of approximately 500 pixels × 200 pixels and enables information to be recorded even faster and with greater precision than with comparable commercial detectors. The system is currently used for material science research at synchrotrons and improves insight in several research areas such as the surface properties of materials. To meet growing demands, a spin-off company was recently founded and the CEO, Christian Broennimann, leads a team of four. The market for these detectors lies mainly in the field of synchrotron radiation.

Meanwhile, the precision work on the individual modules for the CMS experiment continues. The barrel pixel modules are currently being fabricated at PSI at a rate of four to six a day, with a total of 720 modules to be delivered ready for service in late autumn 2007. The PSI pixels will then be on the look-out for passing particles and playing their part in the search for new physics at the LHC.