The LHC, the largest and most complex scientific instrument ever conceived, could not have been built without good organisation, innovative procurement and careful oversight. The same is true of the high-luminosity LHC upgrade.

The completion of the Large Hadron Collider (LHC) in autumn 2008, involving a vast international collaboration and a ten-figure – yet extremely tight – budget, presented unprecedented obstacles. When the LHC project started in earnest in late 1994, many of the most important technologies, production methods and instruments necessary to build and operate a multi-TeV proton collider simply did not exist. CERN therefore had to navigate the risks of lowest-bidder economics, and balance the need for innovation and creativity versus quality control and strict procurement procedures. The impact of long lead times for essential components and tooling, in addition to contingency for business failures, cost overruns and disputes, also had to be minimised.

Procurement for the LHC demanded a new philosophy, especially regarding the management of risk, to keep the LHC close to budget. Excluding personnel costs, the total amount charged to the CERN budget for the LHC was 4.3 billion Swiss francs, which includes: a share of R&D expenses; machine construction, tests and pre-operation; LHC computing; and a contribution to the cost of the detectors. Associated procurement activities covered everything from orders for a few tens of Swiss francs to contracts exceeding 100 million Swiss francs each, from purchases of a single unit to the series manufacturing of hundreds of thousands of components delivered over periods of several years. To give some figures, the construction of the LHC required: 1170 price enquiries and tender invitations to be issued; the negotiation, drafting and placing of 115,700 purchase orders and 1040 contracts; and the commitment of 6364 different suppliers and contractors, not including subcontractors.

Unconventional contracting

CERN’s organisational model also required LHC spending to take account of many national interests and to ensure a fair industrial return to Member States. In addition, CERN made special arrangements with a number of non-Member States for the handling of their respective additional contributions, part of which was provided in cash and part as in-kind deliverables. Procurement for the main components of the LHC fell into three distinct categories: civil engineering; superconducting magnets and their associated components; and cryogenics.

Although the main tunnel for the LHC already existed, the total value of necessary civil-engineering activities was around 500 million Swiss francs, requiring an unconventional division of tasks between CERN, consulting engineers and contractors (figure 1). The next major procurement task was to supply CERN with the LHC’s superconducting magnets, the contractual, technical and logistical challenges of which are difficult to exaggerate. The LHC contains some 1800 superconducting twin-aperture main dipole and quadrupole magnets, as well as their ancillary corrector magnets, all of which are very large and needed to be assembled with absolute precision. The total value of the magnets amounted to approximately 50% of the value of the whole LHC machine, with two thirds of this amount taken up by the dipoles alone (figure 2). CERN opted for an unusual policy to manufacture the LHC magnets, acting both as supplier and client to contractors, and the perils of this approach became apparent when one of the contractors unexpectedly became insolvent.

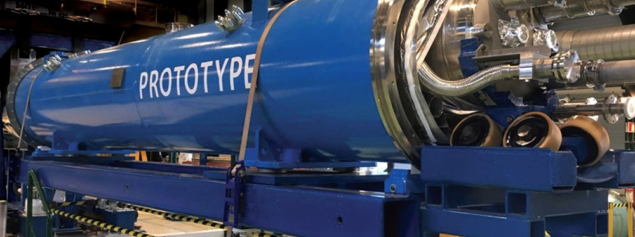

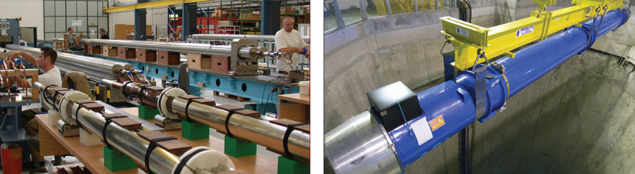

Problems also impacted the third major LHC procurement stage: the unprecedented cryogenics system required to cool the superconducting magnets to their 1.9 K operating temperature. A 27 kilometre-long helium distribution line called the QRL was designed to distribute the cryogenic cooling power to the LHC (figure 3), and, since several firms in CERN Member States were competent in such technology, CERN outsourced the task. But, by the spring of 2003, serious technical production problems, in addition to the insolvency of one of the subcontractors, forced CERN to take on a number of QRL tasks itself to keep the LHC on track.

At the end of 2018, the LHC will enter a two-year shutdown to prepare for the high-luminosity LHC (HL-LHC) upgrade, which aims to increase the total amount of data collected by the LHC by a factor of 10 and enable the machine to operate into the 2030s. Following five years of design study and R&D, the HL-LHC project was formally approved by the CERN Council in June 2016 with a budget of 950 million Swiss francs (excluding the upgrade of injectors and experiments). Tendering for civil engineering and for construction and testing of the main hardware components has started, and some of the contracts are in place. A total of around 90 invitations to tender and price enquiries have been issued, and orders and contracts for some 131 million Swiss francs have already been placed. In June, a groundbreaking ceremony at CERN marked the beginning of HL-LHC civil engineering.

From a procurement point of view, the HL-LHC is a very different beast to the LHC. First, despite the relatively large total project cost, the production volumes of components required for HL-LHC are much smaller. Hence, although the HL-LHC will rely on a number of key innovative technologies to modify the most complex and critical parts of the LHC (see box), these concern just 1.2 km of the total machine’s 27 km circumference. Second, the HL-LHC project is being executed roughly two decades later, in a totally different technological and industrial landscape.

A key factor in much of CERN’s procurement activities is that each new accelerator or upgrade brings more challenging requirements and performances, pushing industry to its limits. In the case of the LHC, the large production volumes were an incentive for potential suppliers to invest time and resources, but this is not always the case with the much smaller volumes of the HL-LHC. Sometimes the market is simply not willing to invest the time and money required as the perceived market is too small, which can lead to CERN designing its own prototypes or working alongside industry for many years to ensure that firms build the necessary competence and skills. Whereas in the days of LHC procurement, companies were more willing to take a long-term view, today many companies’ objectives are based on shorter-term results.

This makes it increasingly important for CERN to convey the many other benefits of collaborating on projects such as the HL-LHC. Not only is there kudos to be gained by being associated with projects at the limits of technology, but there are clear commercial pay-offs. A study related to LHC procurement and contracting, published in 2003, demonstrated clear benefits to CERN suppliers: some 38% had developed new products, 44% had improved technological learning, 60% acquired new customers thanks to the CERN contracts, and all firms questioned had derived great value from using CERN as a marketing reference. Another, more recent, study of the cost-benefits analysis of the LHC and its upgrade is currently being conducted by economists at the University of Milan, providing evidence of a positive and statistically significant correlation between LHC procurement and supplier R&D effort, innovation capacity, productivity and economic performance (see “LHC upgrade brings benefits beyond physics“).

The success of any major big-science project depends on the quality and competence of the suppliers and contractors. There is no “one-size-fits-all” solution in procurement for different requirements and, if a strategy does not work as planned because of unforeseeable conditions, it must be changed. The 36-strong CERN procurement team maintains a supplier database and organises and attends industry events to connect with businesses. It also uses national industrial liaison officers to help find suitable companies in those countries and reaches out to other research labs, all while involving engineers and physicists in the search for new potential suppliers. In the end, the realisation of major international projects such as the LHC and HL-LHC is all about good teamwork between the people responsible for the various activities within the host facility and their suppliers and contractors.

Parts of this article were drawn from the recently republished book The Large Hadron Collider: A Marvel of Technology, edited by L Evans.