Innovation in superconducting radio-frequency (SRF) technology and applications is fundamental for the success of the High-Luminosity LHC (HL-LHC) project and the next-generation particle colliders that will follow. Frank Gerigk, leader of CERN’s RF group, assesses progress on the SRF R&D roadmap and the exacting fabrication and performance requirements already coming into view.

CERN’s commitment to superconducting radio-frequency (SRF) technologies goes back a long way – spanning more than four decades of sustained investment in infrastructure, applied R&D, device- and systems-level innovation, as well as international collaboration with academic and industry partners. If that’s the headline, though, what’s next for CERN’s SRF programme?

A recap of CERN’s SRF achievements is instructive at this point before unpacking the longer-term R&D and innovation roadmap. For starters, SRF cavities – a workhorse technology for frontier accelerators in particle physics, nuclear physics and materials science – were instrumental in pushing CERN’s Large Electron-Positron (LEP) collider to new energy regimes. Through the late 1990s, a total of 288 SRF cavities – each comprising a thin film of superconducting niobium sputtered onto a copper cavity – were installed in LEP-II, providing up to 7 MV/m of accelerating gradient and allowing the machine to eventually reach a centre-of-mass energy of 209 GeV (versus 91 GeV for the original LEP machine). At the start of the millennium, LEP-II was the most powerful SRF installation worldwide.

Fast forward to 2010 and the advent of the HIE-ISOLDE project, the “high-intensity and energy” upgrade to CERN’s radioactive beam facility, which unlocked further investment in the SRF programme. Operationally, HIE-ISOLDE was all about increasing the energy of ISOLDE’s radionuclide beams from 3 MeV/u up to 10 MeV/u through the construction of a superconducting post-accelerator – necessitating, in turn, the design, processing and testing of bulk-niobium SRF cavities along with improved coating performance for thin-film niobium–copper SRF cavities.

CERN engineers duly developed a full prototype of the 100 MHz coated quarter-wave cavities for HIE-ISOLDE before spinning out the technology to industry. Subsequently, however, several of the outsourced cavities exhibited performance limitations, linked to a welding seam in a cavity region with high surface currents. To address this problem, CERN’s RF team came up with an innovative work-around that proved to be crucial in pushing the performance envelope of thin-film SRF cavities.

Put simply, the HIE-ISOLDE cavity was redesigned in such a way that it could be machined out of a single piece of copper with no welds. After coating with niobium and subsequent testing in 2017, the new-look cavity yielded unprecedented surface peak fields of over 60 MV/m and a Q value of 109 at 2.3 K. These figures of merit – well above the qualification target of approximately 30 MV/m (Q = 5 × 108) – gave a clear direction for further R&D on thin-film cavities on seamless copper substrates, with four cryomodules (each containing five SRF cavities) later installed as part of the HIE-ISOLDE upgrade. Significantly, this was also the first time that a “production” cavity using thin-film niobium on copper gave comparable results to bulk-niobium cavities, the performance of which had seen rapid advances over the previous decade as a result of the collective R&D effort geared towards the International Linear Collider (ILC).

Crab cavities in the HL-LHC

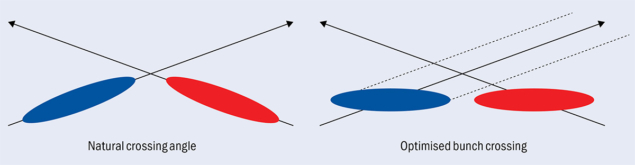

Right now, front-and-centre on the SRF technology roadmap is the HL-LHC project, an ambitious undertaking to increase the integrated luminosity by a factor of 10 beyond the LHC’s design value and, in so doing, open up new opportunities for fundamental physics from 2030 onwards. Once operational, the HL-LHC will use superconducting bulk-niobium “crab cavities” to optimise the bunch crossing at the particle interaction points – thereby increasing and “levelling” the luminosity of the proton–proton collisions. This is achieved by turning the particle bunches slightly before collision and then returning them to their original orientation after the interaction (see “Crafted collisions”).

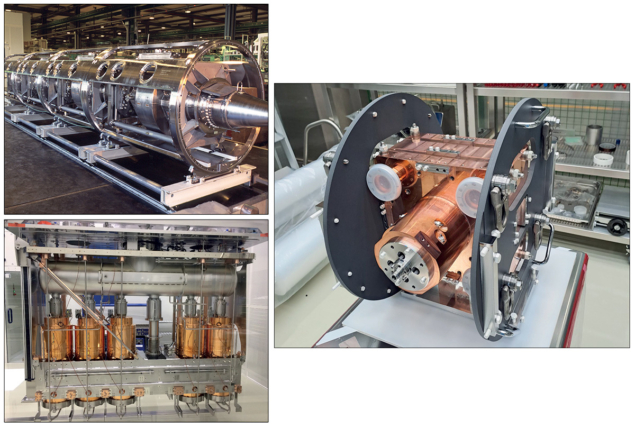

At ATLAS and CMS, there will be two 400 MHz crab cavities deployed for each beam on each side of the experiments – i.e. a total of 16 cavities (eight cryomodules) will be installed during Long Shutdown 3 (LS3), starting in 2026. As the beampipes for the colliding beams are only 194 mm apart, an ultracompact cavity design is necessary to produce the required kick voltage of 3.4 MV per cavity. An intensive R&D effort – involving a network of international partners and funding sources – resulted in two final designs, one for horizontal crabbing (RF dipole, RFD) and one for vertical crabbing (double quarter-wave, DQW). These advanced cavity shapes are roughly four times more compact versus the elliptical LHC accelerating cavities and, as such, present significant challenges in terms of their fabrication.

To test the envisaged technical concepts – and, by extension, demonstrate the crabbing of a proton beam – CERN’s RF development team carried out a beam test of two DQW cavities in the Super Proton Synchrotron (SPS) back in 2018 (CERN Courier May 2018 p18). After construction and processing at CERN, the cavities were subsequently assembled into a cryomodule at the SM18 test facility (a dedicated CERN site for evaluation of superconducting magnets and SRF cavities).

To maximise workflow efficiency, the SPS test stand has a movable platform for the cryomodule, which is connected with flexible elements to the SPS beampipe. This arrangement makes it possible to move the cavities in and out of the beam and thereby reduce the impact on regular SPS operation. The beam tests validated not only the crabbing effect on the circulating proton beam, but also the design and engineering choices for these new cryomodules.

It’s worth noting that the streamlined prototyping of the SPS DQW cryomodule was only possible thanks to CERN’s ongoing investment in SRF R&D and expertise. At a more granular level, that translates into a portfolio of core skillsets spanning niobium-sheet forming and welding; niobium surface chemistry with buffered chemical processing and electropolishing; surface cleaning with high-pressure ultrapure water; assembly of cavities in ISO4 clean rooms; preparation and conducting of cold tests at 2 K; as well as the clean assembly of cavity strings and their integration into full cryomodules with cutting-edge alignment precision.

Collaborate, innovate, accelerate

Following the verification of the underlying technical concepts, CERN established a network of international collaborations for an initial consignment of 10 cryomodules for the HL-LHC plus a spare DQW module and spare RFD module. Division of labour is key here, with German manufacturer RI Research Instruments handling the fabrication and chemical processing of the DQW cavities. After cold-testing the bare cavities at CERN, they are sent back to RI to be equipped with a helium tank and cold magnetic shields, which are provided by Daresbury Laboratory in the UK as part of a joint effort between CERN and the UK’s Science and Technology Facilities Council (STFC).

These so-called “jacketed” cavities return to CERN for another round of cold-testing before being fitted with higher-order-mode (HOM) RF couplers, manufactured in the CERN workshops. Once the performance of the now “dressed” cavities is validated, they are assembled into cryomodules at Daresbury before coming back to CERN for cold-test validation and installation.

Meanwhile, the production of RFD modules takes place in North America as part of the US HL-LHC Accelerator Upgrade Project (AUP) collaboration. In terms of specifics: Fermilab has contracted the Italian manufacturer Zanon for production of bare cavities, with the laboratory retaining responsibility for the chemical treatments, cold magnetic shields, helium vessel and HOM couplers. Fermilab scientists also conduct the cold-tests for the bare, jacketed and dressed cavities. Once the cavities reach the desired performance level, they are shipped to TRIUMF in Canada for re-testing and assembly into cryomodules.

Ensuring this complex collective endeavour remains on track is no small challenge, requiring implementation of well-defined technical interfaces and rigorous performance monitoring while also keeping tabs on day-to-day project scheduling, transportation and thorny logistics issues (including Brexit-related paperwork). More broadly, it’s worth noting that the experience gained from prototyping the crab cavities and cryomodules at CERN has enabled the RF team to establish a stringent quality-assurance system, subsequently shared with all our collaborators to ensure standardised production processes, workflows and system integration.

RF power sources for future accelerators

Alongside the broad-scope R&D efforts around SRF cavity surface losses, parallel work programmes are under way at CERN to increase the efficiency of the RF power sources. As discussed in the main text, the FCC-ee beam needs to receive 100 MW from the RF power system just to compensate for synchrotron radiation losses. The actual required RF power budget therefore increases to 148 MW (including 2 MW for the booster RF) given the anticipated FCC-ee RF power estimation efficiencies of 80%, 90% and 95% for klystrons, klystron modulators and RF distribution, respectively.

Today, however, klystron efficiency is in the region of 55% (which would mean 215 MW for the FCC-ee RF system). Pushing on to that 80% target specification falls within the remit of CERN’s RF group and its focused R&D effort to increase the RF efficiency of high-power klystrons. By applying modern electron-beam dynamics techniques and in-house developed 3D simulation codes (KLYC), the team has already demonstrated tangible results. Last year, for example, the first CERN-designed, high-efficiency klystron was built by Canon and reached exactly the predicted efficiency (53.3%) for a pulsed X-band system (CERN Courier September/October 2022 p39).

For FCC-ee, an advanced, two-stage multibeam klystron for the 400 MHz system is also under development in collaboration with industry partners. The goal is 80% efficiency with much reduced high-voltage requirements (60 kV instead of 110 kV) and a much smaller footprint (2.5 m total length instead of approximately 5.5 m).

Alongside the technology innovation on klystrons, CERN’s RF group is engaged on several other fronts – whether pushing the efficiencies of solid-state based amplifiers or making simple, cost-efficient inductive output tube (IOT)-based amplifiers. The in-house RF team also allocates considerable time and resource – spanning R&D, testing and implementation – to realise power couplers with unprecedented power delivery to the cavities; new tuning mechanisms for the SRF cavities; RF feedback systems and controllers; as well as simulation codes to model longitudinal beam dynamics.

Looking ahead, the next milestone for the HL-LHC crab cavity programme is the testing of the first RFD module in the SPS. Currently, this module is being assembled at Daresbury Laboratory and will be delivered to CERN in September 2023, after which it will be cold-tested in SM18 prior to installation in the SPS during the 2023/24 year-end technical stop.

While the crab-cavity programme will keep CERN’s RF team occupied until the conclusion of LS3 in 2028, preparations are already under way for the 2030s and beyond. Right now, there is a consensus that the next major collider after the LHC will be a lepton machine focused on precision measurements of the Higgs boson. In the case of a circular collider, this will necessitate a powerful RF system to attain collision energies surpassing those achieved by LEP. Two potential candidates are the electron-positron Future Circular Collider (FCC-ee), which would require over 1000 SRF cavities, and a muon collider with more than 3000 SRF cavities (for a 10 TeV centre-of-mass scenario). Meanwhile, a linear collider such as the proposed 500 GeV ILC would necessitate over 7000 SRF cavities.

Progressions of power

Regardless of the eventual scenario, it is evident that the RF system poses a significant technological challenge, with most options involving deployment of SRF cavities at levels an order of magnitude greater than those used in LEP. With rising electricity prices, and growing calls for operational sustainability within high-energy physics, CERN has an obligation to pursue all means of reducing the power consumption of the next big collider. In this context, the CERN RF group is prioritising two strategic R&D objectives: to reduce the surface losses of superconducting cavities while engaging in higher-efficiency RF power generation.

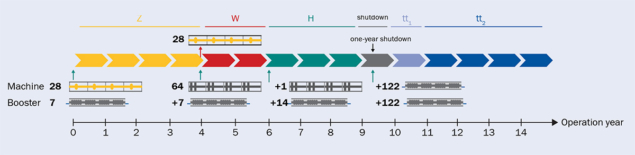

It’s instructive to consider CERN’s SRF strategy in the context of the FCC-ee – and specifically, the potential impact of reduced cavity losses on FCC-ee power consumption and how that is shaping SRF R&D priorities. The present FCC-ee scenario foresees four main stages of operation at increasing centre-of-mass energies, enabling precision measurements of the Z boson (91 GeV), W boson (161 GeV), Higgs boson (250 GeV) and the top quark (365 GeV). The high beam currents needed to support Z and W physics enforce the use of low-frequency cavities (400 MHz) to control the beam-excited HOM power. This means single-cell 400 MHz cavities were chosen for the Z, which will be exchanged for two-cell 400 MHz cavities for the W. At the same time, the booster accelerator will be equipped with 800 MHz five-cell cavities. The number of cryomodules will then increase progressively when moving to the H and ttbar scenarios.

According to projections, the total power consumption of the FCC-ee ttbar scenario is estimated at 384 MW. Within this budget, 148 MW will be needed for the RF power system and 47.5 MW for the associated cryogenics systems. The RF component is dominated by the synchrotron losses (100 MW), which need to be compensated, and the efficiency of the RF power system to generate this power and transfer it to the beam. The cryogenic budget, on the other hand, is related to the surface resistance of the SRF cavities. The maths is simple enough: decrease the SRF surface resistance by a factor of two – and the power consumption of the cryogenic system falls by a factor of two (which, in turn, would cut the size of the cryogenic plant by half).

Is such an outcome realistic, though? The current stated R&D goal for 400 MHz FCC-ee cavities is an approximately 30% reduction of surface losses (versus the LHC cavities) together with a doubling of the accelerating gradient. It’s an ambitious goal and, as such, CERN RF engineers are applying the lessons learned from the HIE-ISOLDE project, where the use of seamless cavity substrates made it possible to increase the peak fields in the cavity while lowering surface losses.

Testing, iteration, continuous improvement

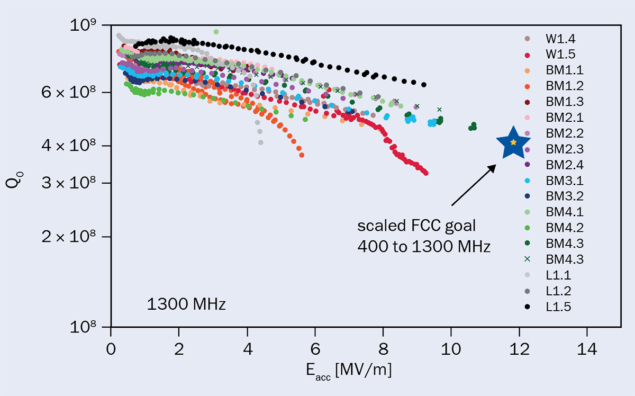

Proof-of-principle tests to date required seamless elliptical cavities, with the CERN workshop able to machine such cavities out of bulk copper pieces, while the technology department’s vacuum group pioneered a method using electroforming. (In the latter, copper is deposited onto an aluminium mandrel, with the aluminium subsequently dissolved to leave behind only the deposited copper layer.) Both approaches were used to make small (scaled) 1.3 GHz cavities, which were then chemically polished and coated using high-power impulse magnetron sputtering (HIPIMS), a specialised method for physical vapour deposition of thin films.

The figure on page 22 (“Numbers game”) shows the results of the first cold tests as well as the target value for the FCC-ee 400 MHz cavities (the latter scaled, in Q value, to be comparable to the 1.3 GHz cavity results). What’s evident from the data is that the seamless coated cavities have clear potential to reach the FCC-ee performance goal – though it’s worth emphasising that these are simplified test cavities without power couplers and without HOM couplers (plus these cavities are around three times smaller in diameter versus the 400 MHz cavities foreseen for FCC-ee).

Qualifiers notwithstanding, these results constitute the first significant step forward in thin-film SRF cavity performance since LEP – underpinned by the enhanced HIPIMS coatings, the use of seamless cavity substrates, and the precision control of cavity surface states during chemistry, coating and cold testing. In terms of next steps, CERN’s R&D effort will focus on further improvements in quality factor (inversely proportional to the surface resistance); extending the field reach (so far limited by the experimental set-up, and not by the properties of the test cavities); and the scale-up to much larger cavities.

The challenges posed by cavity size are twofold: on the one hand, to ensure equal film quality over several square metres of inner surface; on the other, to find a fabrication method that avoids a welding seam at the equator of the cavities. All elliptical cavities built today – whether coated cavities or bulk niobium – are assembled from pre-shaped half-cells. While small 1.3 GHz cavities are straightforward to machine out of a bulk piece of copper, this method quickly becomes uneconomical when considering 400 MHz FCC-type cavities.

For this reason, CERN has initiated a collaboration with KEK in Japan to explore the potential for seamless cavity fabrication via hydroforming (an advanced die-molding process that relies on highly pressurised fluids to shape metals). While the initial results are encouraging, a lot of prototyping and subsequent coating tests will be needed to develop this technology into a process that can be scaled and industrialised. If successful, the hope is that SRF cavity substrates could ultimately be produced like bodywork pieces for cars – and at a fraction of today’s fabrication costs.

Another active area of SRF R&D – and the focus of an ongoing CERN collaboration with Fermilab – involves the 800 MHz multicell bulk-niobium cavities foreseen in the FCC-ee baseline scenario. Over the past decade, Fermilab has pioneered advanced surface treatment methods (such as nitrogen doping or infusion) along with various temperature treatments to tailor the surface resistance of 1.3 GHz bulk-niobium cavities for specific applications.

There’s been significant progress in lowering the surface resistance and the technology has found initial application in the SRF cavities of the Linac Coherent Light Source (LCLS-II) at SLAC in California (with the cavities first being treated and then assembled into cryomodules at Fermilab). In line with the requirements for its Proton Improvement Plan (PIP-II), an ambitious upgrade of the Fermilab accelerator complex, the US laboratory has also started to apply its surface tailoring methods to larger cavities (650 MHz) and, as part of this effort, is keen to include FCC-ee prototypes.

The outer limits

To push beyond the performance limits of today’s coated or bulk-niobium cavities, CERN, Fermilab and other partner laboratories are evaluating new superconducting materials that operate at higher cryogenic temperatures. CERN, for its part, is making sample tests with thin Nb3Sn or Vn3Si layers on copper, while Fermilab scientists are creating a thin layer of Nb3Sn on pure niobium surfaces. The physics is compelling: if the 800 MHz cavities can operate at 4.2 K instead of 2 K with the same surface resistance, the aggregate cryogenic power consumption will be cut by two-thirds.

Along another coordinate, unprecedented accelerating gradients can theoretically be achieved by having multi-layered films on top of niobium or copper cavities, with researchers at CEA in France reporting significant progress with the deposition of single atomic layers onto substrates. In short, with the help of targeted R&D, this looks like a promising path to reducing the SRF surface resistance by 50% on average, though success will ultimately depend on the availability of skilled manpower, state-of-the-art materials processing infrastructure as well as precise diagnostics to evaluate SRF performance.

With this in mind, CERN’s RF group has proposed the construction of a dedicated SRF infrastructure next to the SM18 facility. The new building will provide almost 5000 m2 of space for advanced cavity chemistry as well as clean rooms, cryomodule assembly area and materials cleaning facilities. A full integration study and cost estimate is now complete and the project is under consideration for inclusion in CERN’s next Medium-Term Plan (2023–26).

The future’s bright, it seems, for CERN’s SRF technology programme.

Addendum: In addition to the ongoing collaborative fabrication effort regarding the crab cavities and associated cryomodules, it’s important to highlight the crucial role of the preceding R&D phase. Here, with the financial support of the US LHC Accelerator Research Programme (predecessor of the US HL-LHC Accelerator Upgrade Project), Old Dominion University, JLAB, SLAC and BNL – working together with CERN – designed, developed, prototyped and tested the two crab-cavity types and their HOM damping schemes. Furthermore, we acknowledge support for the R&D effort from UK-STFC and KEK. In the run-up to the FCC R&D effort, and under the US-CERN agreement, JLAB also designed, manufactured and tested the first five-cell 802 MHz bulk niobium cavity, which reached excellent performance with record Q0 value of 3×1010 at 27 MV/m acceleration gradient at 2 K in this frequency regime.