The Industry Liaison Unit at the Institut Laue-Langevin is prioritising engagement with Europe’s technology companies and positioning the neutron science laboratory as a natural extension of the R&D and innovation pipeline. Caroline Boudou and Mark Johnson chart progress to date and the transferable lessons for other large-scale facilities.

The Institut Laue-Langevin (ILL) is an international research centre at the leading edge of neutron science and technology. As a service institute, the ILL makes its expertise available to about 1400 researchers every year across a suite of 40 state-of-the-art instruments. Taken together, those instruments provide the engine-room for a portfolio of unique analytical techniques that enables process, materials and device characterisation far beyond what’s possible in a traditional academic or industry laboratory – as well as spanning a diversity of disciplines from the physical sciences and engineering to pharmaceutical R&D, food science and cultural heritage.

Yet while neutrons are unique and ubiquitous, they are neither widely available nor routinely accessible for applications in front-line research. Intense, tunable neutron beams can only be produced at nuclear reactors (like the ILL) or with high-power proton accelerators (so-called spallation sources). By default, there are no laboratory-based neutron sources for initial training of early-career scientists and preliminary experiments – in contrast to the established development pathway afforded scientists transitioning from laboratory X-ray techniques to the large-scale synchrotron X-ray facilities.

By extension, scientists seeking to access neutrons as a research tool can only do by securing beam time at large-scale facilities. That’s not always straightforward. Large-scale neutron facilities have their own dedicated proposal and contract mechanisms for accessing beam time, adding to perceptions of “impenetrability” for new and occasional users – especially those working in industry. All of which begs a leading question: how can ILL – indeed Europe’s large-scale research facilities generally – build on their successes to date in engaging the industrial R&D community and, in so doing, broaden their collective user base while simultaneously amplifying their societal and economic impact?

Scaling industry engagement

The Industry Liaison Unit (ILU) at ILL, nominally with two full-time staff, leads the laboratory’s industry outreach activities – typically through dedicated local, national and international industry events, all of which are supported by an active online and social media presence. By preparing contracts and agreements as required, the ILU also acts as the interface between the industry partners and ILL instrument scientists who will perform the experiments.

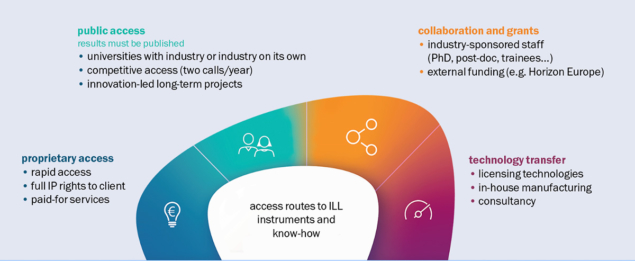

Working with industry can proceed along several routes, each with its own merits. For context, 80% of beam time at ILL is awarded through a competitive peer-review process, with two calls for proposals each year. For this so-called public access model, including precompetitive research at low technology readiness level (TRL), the ILL data policy requires open data and publishable results, with industry partners in many cases collaborating with academic research groups (and, in turn, tapping the latter’s high level of expertise in neutron science). Such “indirect” use of the ILL facilities is the most common access model for industry – though conversely the most difficult for the ILU to capture since the industry partners are not always “visible” members of the research collaboration.

At the other end of the spectrum, and often for projects with a high TRL, industry is able to request proprietary beam time for business-critical research using a paid-for access model. In return, any resulting experimental data remains private, the work can be covered by a non-disclosure agreement, any resulting intellectual property (IP) stays with the client, and experiments are scheduled on an appropriate timescale (usually as soon as possible). Often this sort of work may take the form of a consultancy, in which case the results (rather than just experimental data) are delivered by ILL scientists with the support of the ILU.

In between these limiting cases, precompetitive research collaborations are an ideal way to build long-term industry engagement with ILL. Backed by European and/or national research funding, these initiatives typically run for several years and are often governed by memoranda of understanding. As such, the collaborative model allows an industry partner to gain experience and confidence at ILL while confirming the feasibility (or not) of its R&D goals – all of which can potentially lead on to requests for proprietary beam time. Partners often include established European technology companies – the likes of Rolls-Royce, EDF and STMicroelectronics, for example – or research and technical organisations (RTOs) – among them the French Alternative Energies and Atomic Energy Commission (CEA) and Germany’s Fraunhofer institutes.

Operationally, the main experimental techniques used by industry at ILL are neutron imaging (specifically, radiography and tomography – the former used to reveal the internal structure of manufactured components, while the latter generates 3D images of a sample by measuring neutron absorbance); small-angle neutron scattering or SANS (elastic neutron scattering to investigate the structure of samples at the mesoscopic scale between 1–100 nm); powder diffraction (a form of elastic scattering that reveals atomic and magnetic structures); and strain scanning (which provides insights into strain and stress fields deep within an engineering component). Worth adding as well that neutron imaging takes full advantage of the very intense, continuous neutron beams at ILL and offers potential for significant growth in industry engagement, assuming that capacity can be created to match demand.

Where we are now

It’s fair to say that ILL’s engagement with industry, while on an upward trajectory, remains a work in progress. The latest estimate of “indirect” use of beam time at ILL is that 15% of experiments (about 100 per year) are industry-relevant and likely to involve an industry partner. By monitoring who actually comes to ILL to carry out experiments, the ILU has identified 106 companies using the facility over the last decade. What’s more, proprietary beam time in 2021 involved 26 measurement periods by 14 unique industry customers with an aggregate income to ILL of €0.51 million.

In large part, though, it is pan-European and national research collaborations (precompetitive, low TRL) that continue to stimulate industry interaction with ILL. A case in point is the Integrated Infrastructure Initiative for Neutron Scattering and Muon Spectroscopy (NMI3), in which dedicated workshops were held with diverse industry partners, with the follow-on project, Science and Innovation with Neutrons in Europe 2020 (SINE2020), including an industry consultancy work package with a budget of €1.5 million. The primary focus of the work package was to provide free feasibility studies for companies seeking to evaluate neutron techniques versus their R&D requirements. In all, SINE2020 carried out 37 studies, 14 of which were conducted by ILL.

Two current European projects, BrightnESS-2 and EASI-STRESS, have a common focus on neutron measurements of residual stress – a critical factor, for example, in the mechanical stability of 3D-printed (additive-manufactured) components. The EASI-STRESS project aims to strengthen industrial access and uptake of non-destructive synchrotron X-ray and neutron-diffraction-based characterisation tools. The goal: to enable a better understanding of the formation and progression of residual stresses by direct incorporation of measured data into modelling tools. In parallel, part of the BrightnESS-2 remit is to support ongoing work at ILL about the standardisation of measurements across neutron facilities and instruments, delivering a quality approach that has been formalised as a Neutron Quality Label trademark.

In this respect, it helps that ILL is colocated on the European Photon and Neutron Campus in Grenoble – a geographical convenience that allows close coordination with the adjacent European Synchrotron Radiation Facility (ESRF) when engaging with existing and prospective industry users. The two laboratories are core partners in the EASI-STRESS initiative as well as BIG-MAP, another pan-European project that brings together academic and industry partners on low-TRL battery research as part of the EU’s Battery2030+ roadmap.

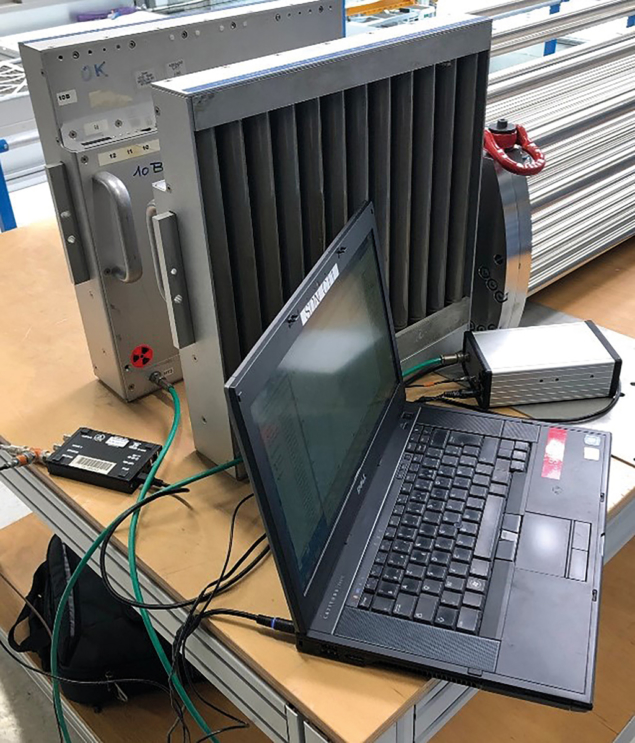

ILL and ESRF are also collaborating within the national IRT Nanoelec project, which enables ILL to showcase its unique analytical capabilities to address key R&D questions in the microelectronics industry. In this context, ILL has created a dedicated irradiation station that allows users to evaluate the sensitivity – and reliability – of electronic components subjected to low-energy (thermal) neutrons.

Industry success stories

Successful case studies for industry engagement can be found along several operational coordinates at ILL. In terms of the proprietary access model – with paid-for beam time plus full IP rights and confidentiality allocated to the customer – projects will typically focus on targeted lines of enquiry relating to a company’s manufacturing, R&D or failure-analysis requirements.

As part of its quality control, for example, French aerospace company Dassault Aviation makes regular use of the ILL’s neutron imaging capability, with the focus on radiographic analysis of high-reliability pyrotechnic equipment for rocket launchers such as Ariane. Materials and process innovation also underpin a series of ILL measurements carried out by OHB and MT Aerospace (a group of companies specialising in space transportation, satellites and aircraft equipment), mainly to investigate residual stress on friction stir welds (when two facing metal workpieces are joined together by the heat generated from friction). The non-destructive determination of strain and stress maps provides primary data to optimise the company’s numerical models while also benchmarking versus destructive lab-based analysis techniques.

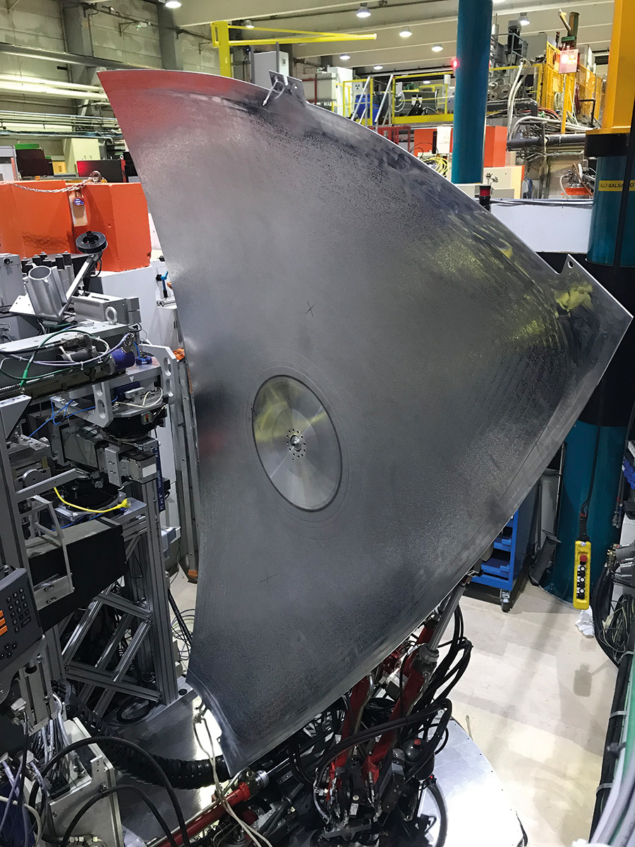

Notwithstanding the proprietary pathway, collaborative projects represent the most popular route for direct interaction between ILL and industrial researchers and RTOs. For example, a joint R&D initiative on metal additive manufacturing (MAM) kicked off in 2018 with the Fraunhofer-Institut für Werkstoff-und Strahltechnik (IWS) in Dresden. Using in-situ laser printing at SALSA, the stress-scanning instrument at ILL, the partners are delivering new knowledge of lasing parameters to ensure robust industrial production of MAM pieces. The initial 24-month project, involving teams from ILL and the Fraunhofer IWS, will be followed by further measurements in 2023 (part of a European Space Agency project that will also include additional X-ray imaging measurements at the ESRF).

InnovaXN: reinforcing industry connections

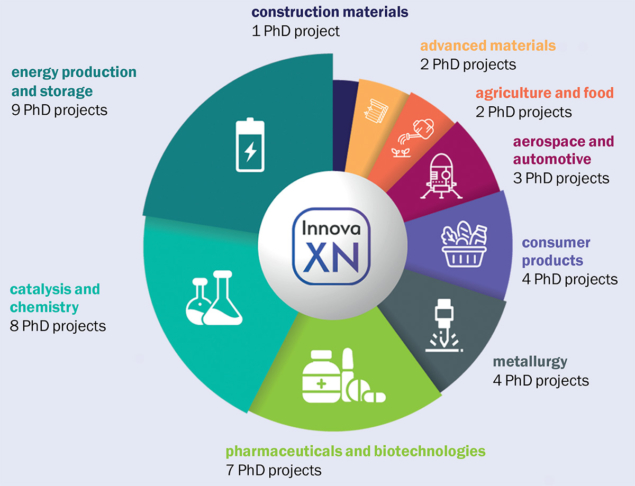

The InnovaXN PhD programme represents a ground-breaking approach to working with industry – a joint initiative between the ESRF and ILL in which 40 research projects are split between the two large-scale facilities (although most projects require the use of both synchrotron and neutron analytical probes). Launched in 2019, the programme is co-funded by the ESRF (25%) and ILL (25%), with the remainder covered by a Marie Skłodowska-Curie Actions grant agreement within the European Union’s Horizon 2020 programme.

All InnovaXN projects have an academic and an industry partner (as well as the ESRF and/or ILL), with each PhD student spending at least three months at the industry partner during the course of their research. In this way, the programme attracts industry R&D teams and activities to ESRF and ILL to explore the use of their unique, cutting-edge synchrotron and neutron capabilities for precompetitive research.

Equally important is the fact that InnovaXN students are exposed to the industry research environment, offering an additional career path post-PhD (either with the industry PhD partner or with another company). This represents the best form of industry awareness for ESRF and ILL, effectively seeding trained scientists in an industry setting. On the other hand, if students end up pursuing an academic career pathway, they will know how to collaborate with industry and how to exploit large-scale facilities when necessary. A win-win.

So far, there have been two intakes of InnovaXN students (in 2020 and 2021). In-progress projects involve 35 unique industry partners (some partners are involved in more than one project), with a quarter of these being SMEs or technology R&D centres. The top three industry sectors covered are energy production and storage; catalysis and chemistry; and pharmaceuticals and biotechnologies – a ranking that reflects the broad reach of neutron and synchrotron techniques for industrial applications.

Another example of collaboration involves Airbus Avionics, which is running a project to mitigate the risks associated with high- and low-energy (thermal) neutrons for avionics programmes. The ILL’s instruments were first used by Airbus to predict thermal neutron risks for state-of-the art semiconductor technologies – with direct measurements being the only way to estimate the real thermal neutron flux inside an aircraft. In 2021, the ILL therefore provided thermal neutron detectors for on-board use in commercial flights, whilst also sharing its technical expertise in this area. The design, development and implementation of advanced neutron detectors is at the heart of the ILL’s activity, as all of its scientific instruments require detectors with unique technical specifications.

Meanwhile, there are many examples of precompetitive research performed at ILL in partnership with industry, often linked to the “indirect” use of the facility highlighted previously. A timely example is the work involving pharmaceutical company AstraZeneca, in which SANS was used to study lipid nanoparticles containing messenger RNA2 – the delivery mechanism for COVID-19 vaccines produced by Pfizer-BioNTech and Moderna. BioNTech also performed a SANS experiment at ILL in 2020.

Lessons learned, new perspectives

With these and other notable success stories to build on, it’s evident that industry use of large-scale research facilities like ILL will remain on an upward trajectory for the foreseeable future. Yet while the laboratory’s near-term thrust is on outreach to industry – raising awareness of the unique R&D opportunities herein – there’s also a requirement for a dedicated selection path for applied R&D projects, with appropriate criteria to give industry streamlined access. Equally important is the ability for companies to study industry-relevant processes, samples and devices on ILL beam lines (“bringing industry to the neutrons”), while delivering experimental data or analysed research outcomes to the industrial customer per their requirements. Improved tracking (and subsequent promotion) of outcomes is another priority, with impact evaluated not just on a financial basis, but acknowledging other metrics such as savings versus energy and raw materials.

Hitting the target on medical radioisotopes

Radioisotope production is a core function of nuclear research reactors. At the ILL, which delivers one of the highest neutron fluxes available within the neutron science community, the focus is on producing low-yield, neutron-rich radioisotopes – and especially nonconventional medical radioisotopes with applications in highly targeted radionuclide cancer therapy. Examples include 177-lutetium, which has been used in the treatment of over 1000 patients to date, and 161-terbium, currently in the preclinical trial phase.

In 2021, ILL income from radioisotope production was close to €1 million, and plans are taking shape to increase production over the medium term. The ILL’s work in this area feeds into PRISMAP, an EU-funded initiative to develop an extensive infrastructure for nonconventional medical radioisotope production.

At the same time, so-called mediator companies are a growing – and increasingly vital – part of the mix. Operating at the interface between large-scale facilities and industry, these intermediary providers offer a broad portfolio of consultancy services – everything except the beam time – to enable industry customers to fast-track their R&D projects by easing access to the unique measurement capabilities offered by the big-science community. Examples include ANAXAM, a spin-off from the Paul Scherrer Institute in Switzerland, and Grenoble-based IROC Technologies – both of which are already connecting industry end-users with large-scale neutron facilities like ILL. Other companies – including Novitom in Grenoble and Finden in the UK – are facilitating industry research at synchrotron facilities like the ESRF, though could ultimately evolve to cover neutron techniques see “Prioritising the industry customer”.

Industry use of large-scale research facilities like ILL will remain on an upward trajectory for the foreseeable future

In the long term, ILL and other laboratories like it must focus on lowering the barriers to engage small and medium-sized enterprises, as well as established technology companies, such that they come to see Europe’s large-scale research facilities as a natural extension of their R&D and innovation pipeline. While indirect industry use of ILL will continue to grow, what constitutes success a decade from now would be an increase in the direct use of the facility by industry for precompetitive and proprietary research. Opportunity knocks.

- The authors would like to acknowledge the role of various colleagues in industry-related work at ILL: Duncan Atkins (ILU); Manon Letiche (IRT Nanoelec); Sandra Cabeza, Thilo Pirling, Ralf Schweins, Lionel Porcar, Alessandro Tengattini, Lukas Helfen (all instrument scientists at ILL); Ed Mitchell, Ennio Capria (both ESRF).

Further reading

F Sebastiani et al. 2021 ACS Nano 15 4 6709.

C Weulersse et al. 2018 IEEE Trans. Nuclear Science 65 1851.