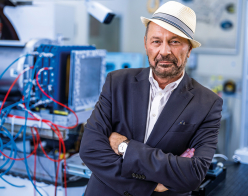

In May CERN Courier covered the Signatures of the Invisible art exhibition, which opened in London earlier this year and showcased the results of a collaboration between physicists from CERN and artists from around Europe. In this article, CERN technician Ian Sexton describes his encounter with an artist.

When CERN started working in collaboration with the London Institute on the Signatures of the Invisible project, I was nominated to work with UK artist Ken McMullen, who needed me to fabricate a scaled metallic model of his paper creation “Crumpled Theory”.

At CERN I make items according to detailed specifications from physicists and engineers. Although the project with Ken was very different, I was surprised to find quite a few parallels between it and my normal work. In both cases time was a constraint, and the goal was the transformation of a requirement or idea into hard reality. However, whereas the pieces I make for CERN have to meet criteria dictated by their functionality, the success of this work was measured by aesthetics and non-functionality.

Light was going to play an important part in the finished work. Ken was going to present the result in the gallery using different lighting effects, which would ultimately determine how it would be perceived. Taking this into consideration, I decided to use lasers during the manufacturing process wherever possible. Lasers are the ultimate sources of light, and their concentrated beams generate intense heat.

I had some initial discussions with Ken to see whether building this scaled piece of art would actually be feasible. Following this early exploration, I proposed how we could make the piece and, after some fine-tuning, we finalized the fabrication method.

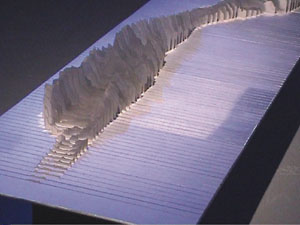

The idea was to represent Ken’s “Crumpled Theory” using five baseplates, each mechanically machined with 20 grooves, along with 100 profiled segments, each of which would be fixed into a groove in the appropriate lateral (x) position.

The first stage was to scan the crumpled piece of paper. This was done in CERN’s metrology department using a helium-neon laser. The surface scans were represented by x and z co-ordinates. A total of 100 scans were made for every 3 mm of the paper, covering its whole length. These co-ordinates were then manipulated and scaled up by a factor of four in both the x and z directions, using a specially written computer program.

After we had written the required numerical control programs, the 100 stainless steel segments were laser cut. A high-power Nd:YAG laser burned through the stainless steel using oxygen as an assist gas to increase cutting efficiency. The resulting 100 profiled segments would be laser welded to the five baseplates produced in CERN’s mechanical workshops by conventional machining methods.

Once the baseplates had been made, the assembly process could get under way. We made calculations to ensure that each segment was correctly positioned before it was attached. All 100 segments were subjected to the trauma of laser-welding, a violent procedure in which the materials are heated up in a fraction of a second, fuse together and then cool quickly, which causes some localized internal stresses. A series of spot welds gave the effect of the segments being stitched to the baseplate.

The finished piece was simply presented on the workshop floor, with sunlight streaming through the blinds. Ken was at CERN just at the right time to get a glimpse of it before it was shipped to England, and he was delighted. His enthusiasm was a most unusual experience for me. Normally on completion of a job at CERN a perfunctory “thank you” is the only response.

I found the whole project, as well as Ken’s reaction on its completion, very rewarding and motivating. Ken’s interest in and passion for the project meant that I thoroughly enjoyed the experience of working with him, and our thought-provoking conversations.