The first part of the end-cap toroid system for the mighty ATLAS experiment, which is under preparation for CERN’s Large Hadron Collider (LHC), will soon be on the road to CERN. The experiment’s two end-cap toroids, each weighing 340 tonnes, will be installed at the outer ends of the ATLAS detector and used to determine precisely the momenta of highly energetic muons emerging from the LHC’s proton-proton collisions.

The main components of the end-cap toroids are being built by Dutch companies under the guidance of NIKHEF in the Netherlands and the Rutherford Appleton Laboratory in the UK, which has design responsibility for the complete end-cap toroid system. Their construction forms an in-kind contribution to ATLAS from NIKHEF, amounting to roughly Ý5 million of the Ý8 million manufacturing cost. Smaller contributions to the toroids will come from several other countries in the ATLAS collaboration.

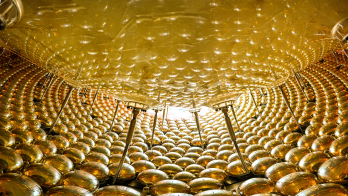

Each of the toroids consists of eight superconducting coils inside an insulating vacuum vessel that is 10.7 m in diameter and 5 m wide. The resulting magnetic field has circular field lines perpendicular to the beams and will deflect the muons in a plane defined by their track and the beam line, allowing much more precise momentum determination than with the inner detector alone.

The first part to be shipped to CERN will be a vacuum vessel, which is scheduled to leave the Netherlands in June. Owing to its size and weight (about 80 tonnes), the move will not be trivial. Split into two halves, the vessel will be shipped from the Netherlands to Strasbourg via the Rhine, and on to Geneva by road.

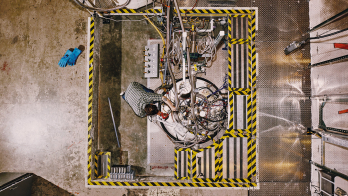

Manufactured by Schelde-Exotech in Vlissingen, the vessel was machined to a precision better than 1 mm at Machine Fabriek Amersfoort in Ijsselstein (near Utrecht) before being taken back to Vlissingen, where the two halves are now being combined. Once the vessel has been assembled, its mechanical construction and vacuum tightness will be tested, after which it will be split again for transport to CERN.

In the meantime another firm, HMA Power Systems in Ridderkerk, has started production of the superconducting coils and their support structures. The eight coils in each vessel will be tightly fixed between eight aluminium keystone boxes, which will keep the coils in place when the field is switched on, exerting radial forces of up to 550 tonnes per coil. Thermal insulation will be provided by the vacuum, a radiation heat shield made by Hatehof in Israel and multilayer superinsulation blankets made by Austrian Aerospace.

To complete the cosmopolitan whole, the 26 km of conductor for the toroids is being supplied as in-kind contributions from Italy (Europa Metalli), Switzerland (ETH/Nexans) and Germany (Vacuum Schmelze). All components of the end-cap toroids are scheduled to be at CERN by the end of 2002 for integration, surface testing and installation underground in the ATLAS experimental hall.