Ultrafast PET detector based on particle-physics know-how proves its ability to sort diamond from rock.

Natural diamonds are old, almost as old as the planet itself. They mostly originated in the Earth’s mantle around 1 to 3.5 billion years ago and typically were brought to the surface during deep and violent volcanic eruptions some tens of millions of years ago. Diamonds have been sought after for millennia and still hold status. They are also one of our best windows into our planet’s dynamics and can, in what is essentially a galactic narrative, convey a rich story of planetary science. Each diamond is unique in its chemical and crystallographic detail, with micro-inclusions and impurities within them having been protected over vast timescales.

Diamonds are usually found in or near the volcanic pipe that brought them to the surface. It was at one of these, in 1871 near Kimberley, South Africa, where the diamond rush first began – and where the mineral that hosts most diamonds got its name: kimberlite. Many diamond sources have since been discovered and there are now more than 6000 known kimberlite pipes (figure 1 overleaf). However, with current mining extraction technology, which generally involves breaking up raw kimberlite to see what’s inside, diamonds are often damaged and are steadily becoming mined out. Today, a diamond mine typically lasts for a few decades, and it costs around $10–26 to process each tonne of rock. With the number of new, economically viable diamond sources declining – combined with high rates of diamonds being extracted, ageing mines and increasing costs – most forecasts predict a decline in rough diamond production compared to demand, starting as soon as 2020.

A new diamond-discovery technology called MinPET (mineral positron emission tomography) could help to ensure that precious sources of natural diamonds last for much longer. Inspired by the same principles adapted in modern, high-rate, high-granularity detectors commonly found in high-energy physics experiments, MinPET uses a high-energy photon beam and PET imaging to scan mined kimberlite for large diamonds, before the rocks are smashed to pieces.

From eagle eyes to camera vision

Over millennia, humans have invented numerous ways to look for diamonds. Early techniques to recover loose diamonds used the principle that diamonds are hydrophobic, so resist water but stick readily to grease or fat. Some stories even tell of eagles recovering diamonds from deep, inaccessible valleys, when fatty meat thrown onto a valley floor might stick to a gem: a bird would fly down, devour the meat, and return to its nest, where the diamond could be recovered from its droppings. Today, technology hasn’t evolved much. Grease tables are still used to sort diamond from rock, and the current most popular technique for recovering diamonds (a process called dense media separation) relies on the principle that kimberlite particles float in a special slurry while diamonds sink. The excessive processing required with these older technologies wastes water, takes up huge amounts of land, releases dust into the surrounding atmosphere, and also leads to severe diamond breakage.

Just 1% of the world’s diamond sources have economically viable grades of diamond and are worth mining. At most sites the gemstones are hidden within the kimberlite, so diamond-recovery techniques must first crush each rock into gravel. The more barren rock there is compared to diamonds, the more sorting has to be done. This varies from mine to mine, but typically is under one carat per tonne – more dilute than gold ores. Global production was around 127 million carats in 2015, meaning that mines are wasting millions of dollars crushing and processing about 100 million tonnes of kimberlite per year that contains no diamonds. We therefore have an extreme case of a very high value particle within a large amount of worthless material – making it an excellent candidate for sensor-based sorting.

Image credit: Eric Welch/GIA.

Early forms of sensor-based sorting, which have only been in use since 2010, use a technique called X-ray stimulated optical fluorescence, which essentially targets the micro impurities and imperfections in each diamond (figure 2). Using this method, the mined rocks are dropped during the extraction process at the plant, and the curtain of falling rock is illuminated by X-rays, allowing a proportion of liberated or exposed diamonds to fluoresce and then be automatically extracted. The transparency of diamond makes this approach quite effective. When Petra Diamonds Ltd introduced this technique with several X-ray sorting machines costing around $6 million, the apparatus paid for itself in just a few months when the firm recovered four large diamonds worth around $43 million. These diamonds, presumed to be fragments of a larger single one, were 508, 168, 58 and 53 carats, in comparison to the average one-carat engagement ring.

Very pure diamonds that do not fluoresce, and gems completely surrounded by rock, can remain hidden to these sensors. As such, a newer sensor-based sorting technique that uses an enhanced form of dual-energy X-ray transmission (XRT), similar to the technology for screening baggage in airports, has been invented to get around this problem. It can recover liberated diamonds down to 5 mm diameter, where 1 mm is usually the smallest size recovered commercially, and, unlike the fluorescing technique, can detect some locked diamonds. These two techniques have brought the benefits of sensor-based sorting into sharp focus for more efficient, greener mines and for reducing breakage.

Image credit: S Connell.

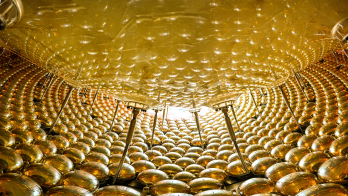

Recent innovations in particle-accelerator and particle-detector technology, in conjunction with high-throughput electronics, image-processing algorithms and high-performance computing, have greatly enhanced the economic viability of a new diamond-sensing technology using PET imaging. PET, which has strongly benefitted from many innovations in detector development at CERN, such as BGO scintillating crystals for the LEP experiments, has traditionally been used to observe processes inside the body. A patient must first absorb a small amount of a positron-emitting isotope; the ensuing annihilations produce patterns of gamma rays that can be reconstructed to build a 3D picture of metabolic activity. Since a rock cannot be injected with such a tracer, MinPET requires us to irradiate rocks with a high-energy photon beam and generate the positron emitter via transmutation.

The birth of MinPET

The idea to apply PET imaging to mining began in 1988, in Johannesburg, South Africa, where our small research group of physicists used PET emitters and positron spectroscopy to study the crystal lattice of diamonds. We learnt of the need for intelligent sensor-based sorting from colleagues in the diamond mining industry and naturally began discussing how to create an integrated positron-emitting source.

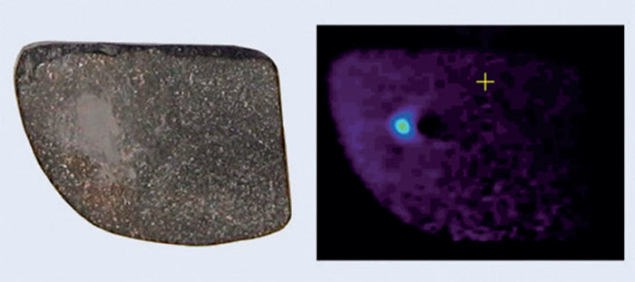

Advances in PET imaging over the next two decades led to increased interest from industry, and in 2007 MinPET achieved its first major success in an experiment at Karolinska hospital in Stockholm, Sweden. With a kimberlite rock playing the role of a patient, irradiation was performed at the hospital’s photon-based cancer therapy facility and the kimberlite was then imaged at the small-animal PET facility in the same hospital. The images clearly revealed the diamond within, with PET imaging of diamond in kimberlite reaching an activity contrast of more than 50 (figure 3). This result led to a working technology demonstrator involving a conveyor belt that presented phantoms (rocks doped with a sodium PET-emitter were used to represent the kimberlite, some of which contained a sodium hotspot to represent a hidden diamond) to a PET camera. These promising results attracted funding, staff and students, enabling the team to develop a MinPET research laboratory at iThemba LABS in Johannesburg. The work also provided an important early contribution to South Africa’s involvement in the ATLAS experiment at CERN’s Large Hadron Collider.

Image credit: S Connell.

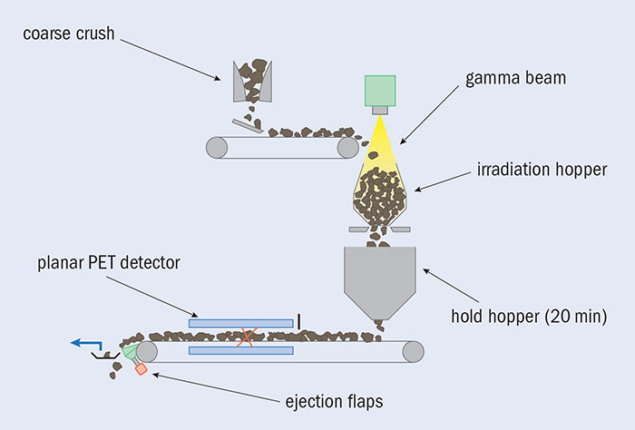

By 2015 the technology was ready to move out of the lab and into a diamond mine. The MinPET process (figure 4) involves using a high-energy photon beam of some tens of MeV to irradiate a kimberlite rock stream, turning some of the light stable isotopes within the kimberlite into transient positron emitters, or PET isotopes, which can be imaged in a similar way to PET imaging for medical diagnostics. The rock stream is buffered for a period of 20 minutes before imaging the rock, because by then carbon is the dominant PET isotope. Since non-diamond sources of carbon have a much lower carbon concentration than diamond, or are diluted and finely dispersed within the kimberlite, diamonds show up on the image as a carbon-concentration hotspot.

The speed of imaging is crucial to the viability of MinPET. The detector system must process up to 1000 tonnes of rock per hour to meet the rate of commercial rock processing, with PET images acquired in just two seconds and image processing taking just five seconds. This is far in excess of medical-imaging needs and required the development of a very high-rate PET camera, which was optimised, designed and manufactured in a joint collaboration between the present authors and a nuclear electronic technology start-up called NeT Instruments. MinPET must also take into account rate capacity, granularity, power consumption, thermal footprints and improvements in photon detectors. The technology demonstrator is therefore still used to continually improve MinPET’s performance, from the camera to raw data event building and fast-imaging algorithms.

Image credit: S Connell.

An important consideration when dealing with PET technology is that radiation remains within safe limits. If diamonds are exposed to extremely high doses of radiation, their colour can change – something that can be done deliberately to alter the gems, but which reduces customer confidence in a gem’s history. Despite being irradiated, the dose exposure to the diamonds during the MinPET activation process is well below the level it would receive from nature’s own background. It has turned out, quite amazingly, that MinPET offers a uniquely radiologically clean scenario. The carbon PET activity and a small amount of sodium activity are the only significant activations, and these have relatively short half-lives of 20 minutes and 15 hours, respectively. The irradiated kimberlite stream soon becomes indistinguishable from non-irradiated kimberlite, and therefore has a low activity and allows normal mine operation.

Currently, XRT imaging techniques require each particle of kimberlite rock being processed to be isolated and smaller than 75 mm; within this stream only liberated diamonds that are at least 5 mm wide can be detected and XRT can only provide 2D images. MinPET is far more efficient because it is currently able to image locked diamonds with a width of 4 mm within a 100 mm particle of rock, with full 3D imaging. The size of diamonds MinPET detects means it is currently ideally suited for mines that make their revenue predominantly from large diamonds (in some mines breakage is thought to cause up to a 50% drop in revenue). There is no upper limit for finding a liberated diamond particle using MinPET, and it is expected that larger diamonds could be detected in up to 160 mm-diameter kimberlite particles.

To crumble or shine

MinPET has now evolved from a small-scale university experiment to a novel commercial technology, and negotiations with a major financial partner are currently at an advanced stage. Discussions are also under way with several accelerator manufacturers to produce a 40 MeV beam of electrons with a power of 40–200 kW, which is needed to produce the original photon beam that kick-starts the MinPET detection system.

Image credit: S Connell.

Although the MinPET detection system costs slightly more than other sorting techniques, overall expenditure is less because processing costs are reduced. Envisaged MinPET improvements over the next year are expected to take the lower limit of discovery down to as little as 1.5 mm for locked diamonds. The ability to reveal entire diamonds in 3D, and locating them before the rocks are crushed, means that MinPET also eliminates much of the breakage and damage that occurs to large diamonds. The technique also requires less plant, energy and water – all without causing any impact on normal mine activity.

The world’s diamond mines are increasingly required to be greener and more efficient. But the industry is also under pressure to become safer, and the ethics of mining operations are a growing concern among consumers. In a world increasingly favouring transparency and disclosure, the future of diamond mining has to be in using intelligent, sensor-based sorting that can separate diamonds from rock. MinPET is the obvious solution – eventually allowing marginal mines to become profitable and the lifetime of existing mines to be extended. And although today’s synthetic diamonds offer serious competition, natural stones are unique, billions of years old, and came to the surface in a violent fiery eruption as part of a galactic narrative. They will always hold their romantic appeal, and so will always be sought after.