CERN is home to a unique innovation ecosystem pioneering advances in vacuum science, technology and engineering. Paolo Chiggiato and Paul Cruikshank provide an insider take.

Vacuum represents a core enabling technology in particle accelerators. Without the required degree of vacuum, the rate of interaction between circulating particles and residual gas molecules would generate several adverse conditions. Particle beams would increase in size and so decrease in luminosity at the interaction points. Beam instability and the rate of particle loss would grow, endangering instrumentation and increasing the background noise in physics experiments. Induced radioactivity and bremsstrahlung radiation would increase risks for personnel and cause damage to the accelerator hardware. What’s more, vacuum is crucial for avoiding electrical breakdown in high-voltage equipment, as well as for thermal insulation of cryogenic fluids, reducing heat “inleaks” to acceptable levels.

Operationally, the level of vacuum required for particle accelerators spans a large range of residual gas densities – from high vacuum (HV, 10–3 to 10–9 mbar) through ultrahigh vacuum (UHV, 10–9 to 10–12 mbar) to extreme high vacuum (XHV, usually defined as 10–12 mbar and lower). Applications in thermal insulation, for example, require a gas-molecule density 10 million times lower than sea-level atmospheric pressure – i.e. less than 10–4 mbar. On the other hand, a modern synchrotron facility requires UHV residual gas densities of ≤ 10–9 mbar, while some antimatter experiments impose a rarefaction requirement in the region of 10–15 mbar. In the most challenging experiments, vacuum is an enclosed space where only several gas molecules per cm3 persist in their random motion, bouncing from one wall of the vacuum vessel to another and able to travel thousands of millions of km before striking another peer (roughly equivalent to the distance from the Sun to Jupiter).

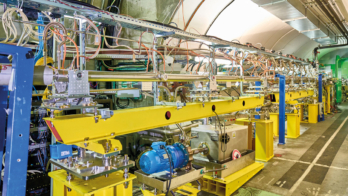

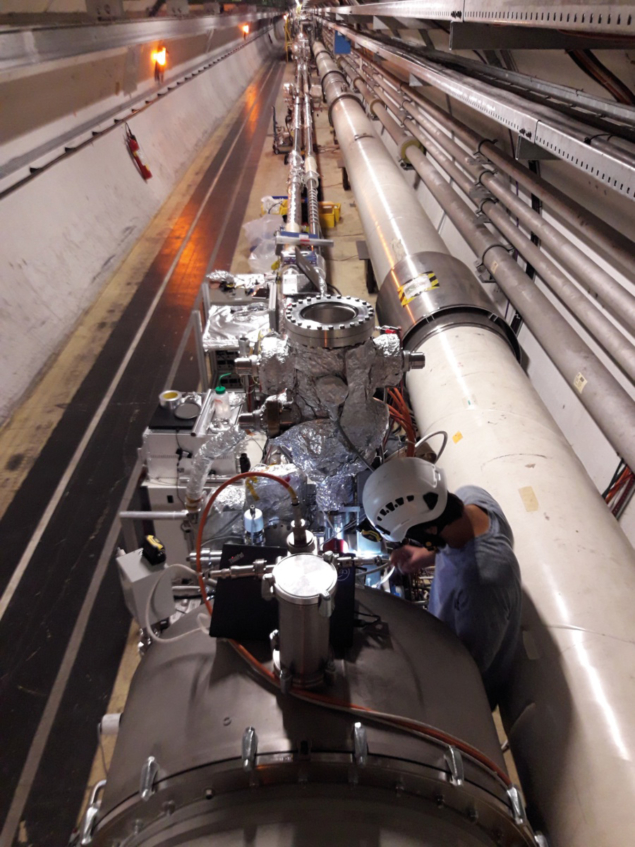

Writ large, it is no surprise that, with more than 125 km of beampipes and liquid-helium transfer lines, CERN is home to one of the world’s largest vacuum systems – and certainly the longest and most sophisticated in terms of particle accelerators. From HV to the UHV/XHV regimes, the complexity of vacuum systems for the particle accelerators at CERN, and other big-science laboratories like it, stems largely from the interaction between particle beams and the surfaces that surround them.

Beam interactions

This “beam–surface dialogue” induces gas desorption from the vacuum system walls, an interaction that can be the dominant source of gas. Indeed, if atmospheric gas is evacuated rapidly from the vacuum system, with no in-leakage of air, it is possible to attain UHV conditions in just a few hours for chamber volumes of the order of a cubic metre. Although the vacuum-system walls release gases spontaneously – mainly water vapour and hydrogen – the choice of suitable materials and thermal treatments reduces the outgassing rates to an acceptable level before accelerator operation. As such, beam-induced gas desorption remains the biggest headache – and this effect, of course, arises only when the particle beams are in circulation.

Beam losses on the chamber walls can be a direct source of gas in the accelerator vacuum system. For the most part, however, beam-induced gas desorption occurs indirectly via the emission of synchrotron light and the beam-induced acceleration of electrons and ions created, for example, by residual gas ionisation. The synchrotron-light-induced desorption is mediated by surface–electron quantum transitions leading to the extraction of photoelectrons, which can desorb residual gas molecules in two ways – initially when leaving the chamber wall, also when striking the wall subsequently. This effect is by far the main source of gas in circular high-energy electron accelerators and plays a significant role in the Large Hadron Collider (LHC), where the critical energy of the emitted photons is around 40 eV (i.e. large enough to extract photoelectrons and induce desorption).

It’s worth noting, though, that there’s no “instant fix” for excessive gas desorption. Even with appropriate chemical surface treatments, accelerator vacuum systems (particularly those for electrons) cannot cope with full beam performance on day one of commissioning. Instead, it is necessary to ramp up the performance of the vacuum system while the beam current is increased in a stepwise fashion. In this way, the dose of particles hitting the surfaces of the vacuum vessel increases (though without excessive beam losses), while desorption yields are reduced via surface cleaning and chemical modification. In the jargon, this optimisation of surface conditioning is known as a “scrubbing run”.

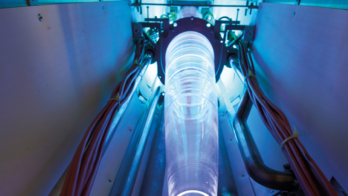

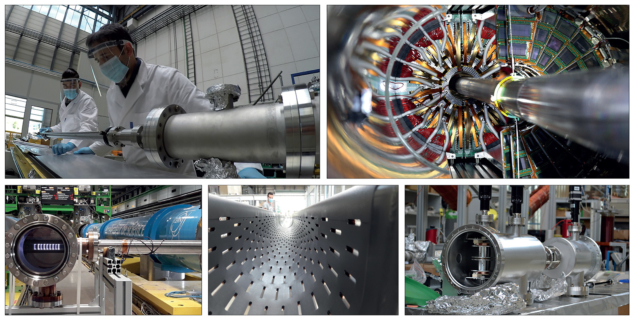

The time taken for surface conditioning can be cut dramatically with the help of nonevaporable getter (NEG) coatings, a concept developed at CERN in the late 1990s. Put simply: the beampipe walls are coated with a micrometre-thick film of Ti–Zr–V alloy that, once heated for a few hours in the accelerator at about 200 °C, provides a clean metal surface that also acts as a pump (i.e. gas molecules are adsorbed by chemical reaction at the surface). During heating, the main reservoir of gas is eliminated as the oxide passivation layer dissolves into the film; after which the cycle repeats whenever adsorption of gas molecules saturates the surface or air venting is necessary.

This NEG capability is deployed at scale by CERN. The 6 km-long beam lines of the LHC’s room-temperature straight sections, for example, are coated entirely with NEG materials, while uptake in several synchrotron research facilities is now envisaged after a pioneering implementation in MAX IV, the Swedish synchrotron. In summary: NEG coatings combine distributed, high-speed pumping with negligible space requirements – a win–win for small-diameter beampipes in the current generation of electron accelerators.

Another significant component of the beam–surface dialogue within particle accelerators is the heating of materials exposed to the circulating beams. One of two possible tracks for the transfer of thermal power is the interaction between the electromagnetic field generated by the beams with the surrounding materials, a process that induces electrical currents on the beam-facing surfaces.

Support for projects like the HL-LHC requires full cognisance of some pretty harsh operating environments

These currents may in turn give rise to Joule heating, typically mitigated by using a good electrical conductor (like copper) as the material of choice for the beampipes or as a layer deposited on stainless steel, usually via electrolytic techniques. Geometrical discontinuities of the vacuum chambers may also result in resonant interaction with the beam, creating enhanced local power dissipation in trapped modes – a problem that can be solved through optimised design of the vacuum chambers and their transitions.

Taken together, these mitigation measures have another highly beneficial side-effect. Beam-induced surface currents generate electromagnetic fields which, in turn, interact back with the beam, potentially disrupting its characteristics or its long-term stability in the accelerator. As such, the overall drive to reduce the impedance of the vacuum system (and of all in-vacuum components) results in longer beam lifetimes and preserved beam emittance, ultimately leading to higher collision rates in physics experiments.

The heat is still on

Ongoing innovation will be essential, however. In the next generation of high-energy proton accelerators operating with superfluid helium – the proposed Future Circular Collider (FCC-hh) is a case in point – the impedance of the beampipes could prove detrimental for the global heat-load balance of the cryogenic system. To counter this heat source, CERN has initiated an ambitious feasibility study in which the inner walls of vacuum chambers are coated with high-temperature superconductors (HTS). Owing to the much-reduced electrical losses of superconductors versus normal metals, successful use of HTS promises to yield a considerable impedance reduction. It’s early days, but initial results with HTS rare-earth barium copper oxide (ReBCO) test coatings are extremely encouraging.

At the same time, synchrotron radiation and electrons hitting the walls of the vacuum system also convey part of the beam power to the surrounding vessels. The multiplication of impinging electrons by the surface and their acceleration by the beam – a process known as electron multipacting – is of concern for cryogenic systems. In the LHC, for example, the heat load is intercepted by an intermediate wall that’s maintained at a temperature of 10–20 K rather than 1.9 K (which is the temperature of the cold bore – i.e. the chamber in tight contact with the magnet). Underpinning this arrangement is the insertion into the cold bore of an additional pipe – the so-called beam screen – which is made of copper-colaminated stainless-steel and cooled by a dedicated helium circuit. The beam screen and cold bore in turn communicate through pumping slots so that gas molecules are cryoadsorbed on the coldest surface.

CERN’s vacuum roadmap: collaboration is key

The evolution of vacuum technology and engineering at CERN is strictly aligned versus accelerator operation and priorities; the organisation’s fundamental science programme; and, at a high level, the 2020 update of the European Strategy for Particle Physics. As the restart of the LHC physics programme approaches (slated for early 2022), the reliability of the CERN vacuum system is our primary focus – especially after a shutdown that will have run to more than two years.

For sure, 2021 will be an intense period for the CERN vacuum team. An immediate concern is the restart of beam circulation in vacuum systems that were open to the air for planned interventions and modification – sometimes for several days or weeks. The heat load generated by the beams in the LHC’s arcs will be under the spotlight as well as the performance of the upgraded LHC’s injector chain. There is no doubt that our nights will be filled with worries – worries that will hopefully dissipate as new science breakthroughs are announced for the LHC’s beams and detectors.

Maintaining momentum

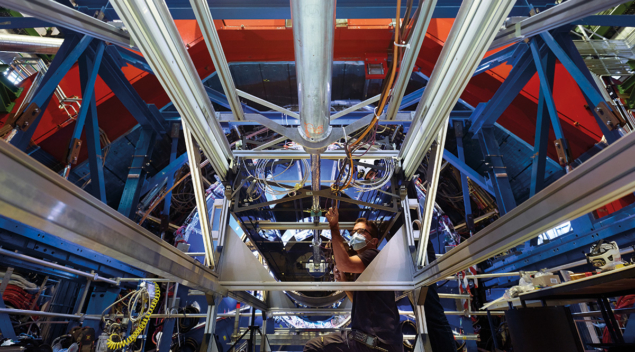

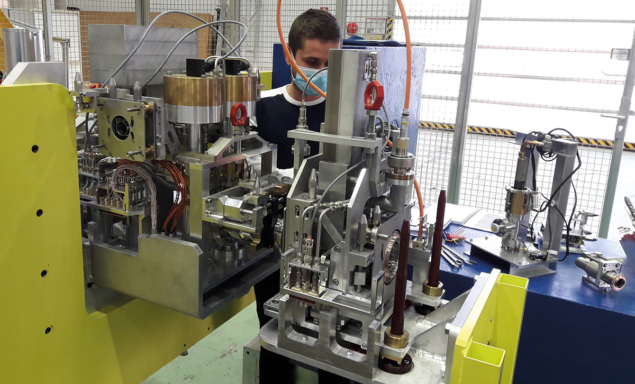

In parallel, we will maintain the pace of the HL-LHC programme, implementing vacuum innovations elaborated in the past five years. Chief among them are the new beam screens for the triplet magnets of the two high-luminosity experiments – CMS and ATLAS. This advanced concept integrates a carbon coating (as electron multipacting suppressor) and tungsten blocks (to absorb collision debris before it interacts with the magnets). Design optimisation required several iterations and the running of multiphysics programs. The vacuum team subsequently evaluated the mechanical stability of the HL-LHC beam screen during the electromagnetic and thermal transient generated by magnet quench (i.e. a sudden loss of superconducting properties). Experimental investigations of the vacuum performance – via measurement of adsorption isotherms – allowed us to choose 60 K as the operational temperature for the new beam screen.

Another notable HL-LHC achievement is the vacuum module installed between the last focusing magnet of the accelerator and the high-luminosity experiments. Referred to as VAX, this arrangement comprises a compact set of vacuum components, pumps, valves and gauges installed in an area of limited access and relatively high radioactivity. As such, the VAX design is fully compatible with robot intervention, enabling leak detection, gasket change and complete removal of parts to be carried out remotely and safely. The direction of travel is clear: robotic technologies will have a pivotal role to play in the vacuum systems of next-generation, high-intensity particle accelerators.

Joined-up thinking

Operationally, it is already time to prepare CERN and a new generation of vacuum experts for the post-LHC era. Our reference point is the aforementioned European Strategy for Particle Physics, with its initial prioritisation of an electron–positron Higgs factory to be followed, in the long run, by a 100 km-circumference proton–proton collider at “the highest achievable energy”.

These accelerators will push vacuum science and technology to the limit, amplifying the challenges that we have today with the LHC. Yet there’s plenty of encouraging progress to report. An optimised design for the vacuum chambers is already in the works, thanks to advanced simulations of synchrotron radiation and gas molecule distribution performed using CERN-maintained software. Furthermore, the Karlsruhe Research Accelerator (KARA) in Germany reports excellent results in its evaluations of the proton–proton prototype vacuum chamber. The biggest challenge remains cost: engineering solutions adopted at the km scale cannot be implemented for systems 10 to 100 times longer – the vacuum system would be prohibitively expensive.

Herein lies an opportunity – and more specifically a call to arms for vacuum specialists to work collaboratively across their respective disciplines to imagine, and subsequently deliver, the technology innovations that will address the economic challenges of big science in the 21st century. The potential synergies are already evident as the next generation of particle accelerators takes shape alongside new concepts for advanced gravitational-wave telescopes. Diverse physics initiatives with a common interest in driving down the cost of their enabling vacuum systems.

A granular understanding of the fundamental physics certainly helps here. While synchrotron radiation power depends only on the beam parameters, the contribution of electrons to the heat load depends on the surface parameters, above all the secondary electron yield – i.e. the ratio of emitted electrons versus incident electrons. This important characteristic of the surface walls decreases as the dose of impinging electrons accumulates – an additional outcome of beam conditioning. That said, such a decrease takes time and dedicated beam runs, while the mechanism of beam conditioning seems more complex than at first anticipated (as observed during Run 2 of the LHC from 2014–2018). In terms of specifics, the heat load transferred in the beam-screen cooling circuit was found to be higher than expected in four of the LHC’s eight arcs. CERN’s surface experts investigated several surface characteristics to understand this phenomenon and, finally, spotted anomalous behaviour in copper oxide that could lead to a less effective decrease of the secondary electron yield.

The sheer scale of CERN’s vacuum infrastructure represents an engineering challenge in its own right

To circumvent the need for additional beam conditioning, CERN’s vacuum group has developed amorphous carbon coatings with very low secondary-electron yields to effectively prevent electron multipacting. Such thin films are the baseline for the beampipes of the final focusing magnets for the High-Luminosity LHC (HL-LHC) upgrade, presently under way. The carbon coatings have also been implemented in selected areas of the Super Proton Synchrotron (which injects protons into the LHC) to reduce the direct effect of electron clouds on beam performance.

Another countermeasure to electron multipacting involves increasing the roughness of the walls of the vacuum vessel, such that secondary electrons are intercepted by the surfaces before they can be accelerated by the beam. In this instance, the CERN vacuum group is implementing laser treatments developed by two UK research centres – STFC Daresbury Laboratory and the University of Dundee. The laser, which is introduced into the beampipes using a dedicated robot from GE Inspection Robotics, engraves small grooves azimuthally, with a spacing of a few tens of micrometres. Furthermore, the redeposition of ablated material superposes nanometric particles that enhance the electron-capture effect.

Measurement and control

Zoom out from the esoteric complexity of beam–surface interactions and the sheer scale of CERN’s vacuum infrastructure represents an engineering challenge in its own right – not least in terms of vacuum metrology, diagnostics and control. In all, more than 12,000 vacuum instruments – gauges, pumps, valves and associated controllers with almost a million configuration settings – are managed via a flexible database running in the Cloud. Work is well advanced to mine the vast amounts of data generated by this network of vacuum systems – ultimately creating a “data-streaming pipeline” that will integrate the latest analytics software with a new generation of open-source diagnostic and reporting tools.

Meanwhile, at the operational sharp-end, the measurement of extremely low pressures remains a core competency of the CERN vacuum team. This capability preserves, indeed builds on, the legacy of the Intersecting Storage Rings (ISR), the world’s first hadron collider and a pioneering environment for vacuum technology during the late 1960s and 1970s. The vacuum gauges operating at CERN today in the 10–7–10–12 mbar range are copies of the original models adopted for the ISR, while those in use in CERN’s R&D laboratories and in antimatter experiments (for measurement down to 10–14 mbar) are the result of further developments in the late 1970s.

Studies of vacuum gauges to provide continuous measurement at even lower pressures are also under way at CERN, often in collaboration with Europe’s metrological community. In the framework of the EURAMET-EMPIR programme, for example, CERN vacuum experts have participated in the development and characterisation of a vacuum gauge with an ultrastable sensitivity for the transfer of vacuum standards amongst European research institutes (see “Vacuum metrology: made to measure”).

More broadly, support for projects like the HL-LHC requires full cognisance of some pretty harsh operating environments. Fundamentally, increasing beam currents means that vacuum systems and their electronic control circuits are more and more susceptible to radiation damage. A key determinant of the global cost/performance of a large-scale vacuum system is the deployment of electronics in the accelerator tunnels – with weaknesses in the devices gradually revealed through increasing radiation exposure. With this in mind, and by using radiation sources available on site as well as at other European research institutes, the CERN vacuum team has been busy evaluating the “radiation hardness” of hundreds of critical components and electronic devices.

Looking to the future, it’s evident that major accelerator initiatives such as the HL-LHC and the proposed FCC will maintain CERN’s role as one of the world’s leading R&D centres for vacuum science and technology – a specialist capability that will ultimately support fundamental scientific advances at CERN and beyond.