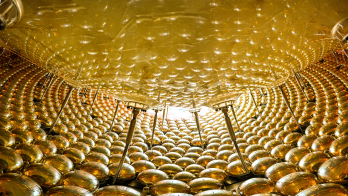

Assembly of the Compact Muon Solenoid (CMS) detector, being built for physics at CERN’s Large Hadron Collider, reached an important turning point in October. The return yoke for the detector’s 4 T superconducting solenoid is now completely assembled, with a central section supporting the 7.6 m diameter, 13 m long outer shell of the solenoid’s vacuum tank. Attention is now shifting towards installation of the solenoid and sub-detectors.

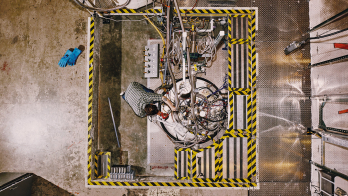

As components arrive at CERN from around the world, an assembly team coordinated by Zurich’s ETH and CERN ensures that each new piece of the puzzle is carefully slotted into place. A magnet test is foreseen for early 2005, by which time several CMS subdetector systems, including the hadronic calorimeter and muon system, will be largely complete, cabled and tested.

So far, this giant 3D puzzle has produced few difficulties, thanks largely to the establishment of an engineering and integration centre, jointly supported by ETH and CERN, 6 years ago. Staffed by designers and engineers from both partners, and supplemented by visiting engineers from other CMS institutes, the centre scrupulously controls the space allocated to each subsystem and the no-go zones separating them, ensuring smooth integration of detector elements.

Work on the hadron calorimeter is well advanced, with the barrel nearing completion and the brass absorber of the first hadron endcap calorimeter gradually taking shape. Barrel and endcap muon chambers were successfully installed during the summer, and a dry run of the solenoid coil insertion was also recently conducted. This involved the inner shell of the vacuum tank, modified to simulate the coil, being rotated from vertical to horizontal and inserted into the outer shell. Particular attention is now being paid to the layout and connections of the hundreds of kilometres of cables, gas lines and water pipes that will supply the CMS detector.

With the first letter of the CMS acronym very much in mind, and hermeticity a watchword for achieving good physics performance, the CMS detector is being built to exacting mechanical tolerances. Muon chamber supports on the 15 m diameter endcap yoke disks, for example, are positioned to an accuracy of 0.2 mm. CMS is placing great emphasis on planning, and so it was with some satisfaction that the collaboration received the news from the committees charged with overseeing installation that “there is every reason to believe that CMS will have a working detector ready for first collisions in April 2007”.