As the many pieces of the Large Hadron Collider (LHC) and its experiments come together at CERN, Canada’s contributions to the project are moving into their final positions. One of the hadronic end-cap calorimeters built at the Tri-University Meson Facility (TRIUMF) was recently installed in the ATLAS detector, and the first of the resistive twin-aperture quadrupoles for the “beam cleaning” regions in the LHC, designed at TRIUMF and built by Alstom Canada Inc, should be installed in the tunnel in June. However, the pulse-forming networks (PFNs) for the LHC injection kickers will soon become the first components from Canada to be completely installed.

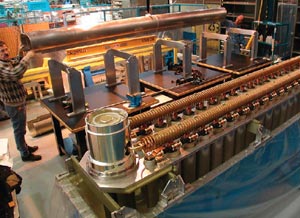

The LHC will have fast-pulsed magnet systems – the kickers – to inject the two proton (or heavy-ion) beams into the main ring. Two pulsed systems are required, each comprising four magnets, four PFNs and four high-voltage thyratron-based switches. Each PFN consists of two 28 cell, 10 Ω lines connected in parallel at their ends. To kick the beam buckets from the Super Proton Synchrotron into the LHC ring, each system must produce a magnetic field pulse of 1.3 T.m strength, with a rise time of not more than 900 ns, an adjustable flattop duration up to 7.86 μs, and a fall time of not more than 3 μs. The total ripple in the field must be less than ±0.5%.

The energy in a PFN is provided by a resonant-charging power supply (RCPS), which is used to reduce as much as possible the number of untriggered discharges of the thyratrons. The performance of the electrical circuit of the complete system, including a 66 kV RCPS and a 5 Ω PFN, was carefully simulated, and components were selected for the PFN on the basis of theoretical models in which a ripple of less than ±0.1% was attained.

As part of the Canadian contribution to the LHC, TRIUMF has built and tested in-house five RCPSs and nine PFNs. After shipment to CERN, the RCPSs and PFNs are thoroughly tested before insertion into the tunnel sections where injection into the LHC will occur. Installation began in May 2005, and the final systems should be installed this spring.