The largest piece of Canada’s $41.5 million (€32.5 million) contribution to the Large Hadron Collider (LHC) was completed in 2003 with the delivery of the last of 52 twin-aperture quadrupole magnets to CERN. These warm magnets (48 plus four spares) will be installed in the two beam-cleaning insertions of the LHC, where heating by lost beam prohibits the use of superconducting coils. The magnets, based on a CERN design, were made by ALSTOM Canada in Tracy, Quebec, with considerable input and design assistance from engineers at TRIUMF and CERN. Their small apertures (46 mm) and high gradient (35 T/m) meant that the 3.4 m long modules had to be assembled with unusually high tolerances to achieve the necessary field quality.

A prototype magnet was completed and shipped to CERN in May 1998 for mechanical and magnetic field measurements. As these measurements showed that the desired field quality had not been achieved, improvements were made in the lamination design, in the punching precision and in welding the stacks of laminations without distortion. Stronger stacking tables and a separate half-magnet assembly table were also constructed. These changes led to the first series magnet, which was completed in March 2001 and fully met the specifications. ALSTOM then proceeded to meet and eventually surpass their planned production rate of two magnets per month. Mechanical measurements were carried out at the factory to qualify the magnets prior to shipping, and detailed magnetic field measurements were made at CERN.

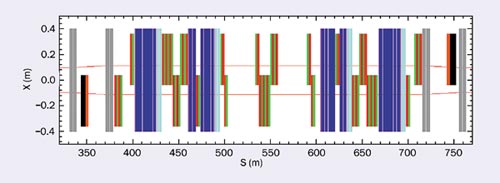

Autumn 2003 also saw the finalization of another feature of the cleaning insertions to which Canada has made a significant contribution – the arrangement of the 48 quadrupole modules and 40 collimators. In collaboration with CERN, TRIUMF has been responsible for developing a computer code to determine the optimum positions for the horizontal, vertical and skew collimator jaws, and for certain aspects of the beam optics, including matching to the arcs. An unusual feature is that as each of the focusing quadrupoles is composed of six of the magnet modules, the two beams of the LHC can be tuned independently, by wiring some modules with one beam aperture as F (focus) and the other as D (defocus), and other modules with both apertures acting in the same sense.

The decisions in 2002 to switch from copper to (much longer) graphite collimators to avoid the possibility of meltdown in an accident, and to install only half-length collimators at first, provided last-minute challenges with regard to space, impedance and collimation. Nevertheless, for the standard primary and secondary collimator apertures, which are six and seven times the rms beam width, respectively, it has been possible to find solutions that keep the collimation inefficiency below the target levels of 0.05 at injection and 0.001 at 7 TeV, with an acceptably low impedance, during phase 1, the first years of LHC physics. Moreover, sufficient space remains for the phase 2 collimators, which will support LHC operation with nominal parameters.

The remaining contributions to the LHC from TRIUMF – the major equipment for the injection kickers, the development of digital acquisition boards for the beam position monitors and beam-beam interaction studies – are also entering their final stages.