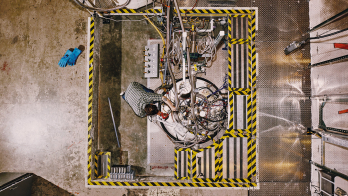

The world’s largest superconducting solenoid magnet for the CMS experiment at CERN’s LHC collider recently took an important step towards completion when the first ring of its barrel yoke was assembled near Munich. The order for the manufacture of the yoke was given to Germany’s Deggendorfer Werft und Eisenbau GmbH (DWE) in the largest individual contract for a high-energy physics experiment ever placed. The contract was worth some 23 million Swiss francs. Following a worldwide call for tender, the order for the CMS barrel iron yoke and vacuum tank was signed on behalf of the CMS collaboration between DWE and the Swiss Federal Technical Institute ETH Zürich in April of last year.

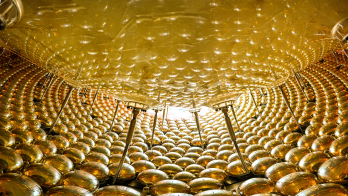

The CMS solenoid coil will measure 6 m in diameter and 12.5 m in length. At 4 T it will have the highest field of any magnet of its kind and it will be able to store some 2.5 GJ of energy. Its return yoke will weigh 11 000 tons and will consist of two endcaps, each of which will have three disks, and a barrel yoke that is made up of five rings.

The magnet system was designed by a CMS team and was financed by a consortium of CMS funding agencies in Switzerland, the US, Germany, Cyprus, Russia and the CMS Common Fund. DWE is coordinating the magnet’s construction with subcontractors in the Czech Republic, France, Germany, Italy, and the Russian Federation.

Eight of the ten feet for the yoke are being provided as an in-kind contribution by Pakistan, where they are being manufactured by the company Scientific Engineering Systems. China will be donating the supports for the endcaps. They are being manufactured in China by the Hudong Heavy Machinery Company. The final assembly of the yoke will commence in July 2000 at CERN. After being tested on the surface, the magnet will be lowered, ring by ring, to the CMS experimental hall some time towards the end of 2003.