Built for research in nuclear physics, the cyclotron at Indiana University now has a new role, which includes radiation testing for high-energy particle physics.

The Indiana University Cyclotron Facility (IUCF) was originally built as a laboratory for medium-energy nuclear physics, and began operations in 1975. By the 1990s the research programme had begun to diversify, and in 1998 the National Science Foundation decided to discontinue funding of the cyclotron for basic research. Since then, the facility has undergone several dramatic changes, and a medical clinic for cancer treatment using the 205 MeV proton beam from the cyclotron is nearing completion. At the same time, the radiation effects research programme (RERP) is being expanded, and is proving valuable for testing detectors and components for high-energy particle physics.

The beginnings of the RERP at the IUCF go back to the early 1990s, when a group from NASA began to use the proton beam to simulate the space radiation environment. Since then, the radiation effects programme has grown steadily. Studies of single-event upsets (SEUs), displacement damage or other effects of radiation on micro- or opto-electronic devices are routinely conducted. Qualification of commercial-off-the-shelf (COTS) components for applications in space are also part of the radiation effects programme. In addition, the radiation hardness of materials, such as adhesives for use in high radiation environments, is being investigated.

So far, only one beamline has been available for research into radiation effects. However, about two years ago NASA chose the IUCF as their main test facility for the devices intended for use on the International Space Station. Subsequently, two new, state-of-the-art beamlines for radiation effects research were designed in collaboration with NASA and are now under construction. The first new radiation effects research station will become available in June, while the second will be operational later in the year. The radiation effects studies will be conducted concurrently with proton therapy operations.

At the IUCF, protons are extracted from the cyclotron at 205 MeV and delivered by a fast kicker system to both the medical facility and to each of the new radiation effects stations. The kickers deliver a 0.4 ns wide pulse every 100 ns. Beryllium degraders that are well upstream of the radiation effects stations may be used to degrade the beam energy to 40, 65, 90, 120 or 150 MeV. Momentum analysis downstream of the degrader guarantees nearly mono-energetic beams at the location of the device under test. The available fluxes are between 102 and 1011 protons/s/cm2. The new irradiation stations feature spot sizes between 2 and 40 cm in diameter, so whole laptops may be irradiated at the location of the largest beam spot. For each irradiation, the dose is automatically measured with a calibrated secondary electron monitor and then logged.

Tests for CMS

Although traditionally associated with space applications, radiation hardness assurance is becoming crucially important for detector components for high-energy collider experiments. It is a particular concern for all the teams that are building detectors for CERN’s Large Hadron Collider (LHC) where the proton beams will cross each other 40 million times per second; at the highest luminosity (1034 cm-2 s-1) 25 proton-proton collisions per crossing are expected. To this end, Fermilab has established a programme at the IUCF for the radiation qualification of the electronics it is developing for the Hadron Calorimeter (HCAL) for the CMS experiment.

The CMS HCAL is a sampling calorimeter, composed of brass absorber and scintillating tile with embedded optical fibre readout, which is used to determine the energy of an event. Its front-end electronics accounts for approximately 10,000 of the CMS detector’s 16 million readout channels. During 10 years of CMS operation, the front-end components are expected to be exposed to a total ionising dose of approximately 300 Rad, and a neutron fluence of 1.3 x 1011 n/cm2.

Although not considered a high radiation region within CMS, the performance of radiation-sensitive devices can degrade in the HCAL environment. Radiation-induced pathologies include non-destructive effects such as SEUs that cause data corruption due to bit-flips and potentially catastrophic failures such as latch-up, which can cause over-current damage to chips. Both effects are caused by single-particle interactions in a device.

A key to determining the radiation specifications for a component is understanding its function in the system. An error rate of 1 SEU per day for a chip may not seem like a large figure, but multiply this by 10,000 channels and the impact can be quite significant. Because designing redundancy into the system is not always practical, it becomes important to select components that can survive in a radiation environment carefully.

The HCAL front-end readout and control monitoring boards have approximately 20 different components that need to be radiation qualified. Several of these are custom-designed chips, but the majority are COTS components, ranging from temperature sensors to field programmable gate arrays (FPGA). Radiation-hard versions of the COTS chips are sometimes available, but at a cost that is prohibitively expensive. Fermilab’s strategy is to purchase non-radiation-hard versions and validate them. The combination of rigorous testing at proton beam facilities such as the IUCF and designing for radiation tolerance is expected to yield reliable electronics for the HCAL that will survive 10 years of operation in the LHC environment.

The majority of radiation assurance testing for the CMS HCAL front-end electronics has taken place at the IUCF, where the 205 MeV proton beam is ideal because the protons are of high enough energy to induce single-event effects. Cumulative damage can also be studied. The programme of tests has been conducted over a period of 2.5 years, and has yielded many interesting results (Whitmore et al. 2002). For example, FPGA testing revealed SEU susceptibility, and consequently the FPGA programming was modified to allow for triple redundancy in critical elements of operation. Tests of clock distribution chips showed that certain logic families were more sensitive to radiation conditions than others, and tests of shift registers revealed that SEU-tolerant cell layout was required for the design of the digital sections of the custom-designed chips. The results from prototype HCAL system board tests look promising, with no indication of latch-up problems at exposures up to 50 times that expected in 10 years of CMS operation. The final board tests, including monitoring of SEUs, were scheduled for March 2003 at the IUCF.

MiniBooNE oil

Aside from applications that investigate the potentially damaging effects of ionizing radiation, the RERP beamline may also be used to test the overall performance of detectors and detector components. For example, the neutrino physics group at the IUCF has used the RERP beamline for tests of the scintillation properties of mineral oil and for prototype detector studies. The beam current can be reduced so that the proton rate is quite low (~1 kHz), and tests requiring single proton tracks can be conducted.

The recently commissioned MiniBooNE neutrino experiment at Fermilab uses 800 tonnes of mineral oil as a neutrino detector medium. Charged particles in the mineral oil predominantly produce Cerenkov light. However, a small amount of scintillation light is also produced. It is important to quantify the amount and time distribution of the emitted scintillation light in order to understand the detector response to charged particles, especially particles with velocities below the Cerenkov threshold.

The tests at the RERP facility measured the strength and time distribution of the scintillation light emitted from the MiniBooNE mineral oil. Since the cyclotron beam energy is well below the threshold for Cerenkov light production (Tth = 341 MeV), any light emitted from proton tracks in the oil sample must be due to scintillation. Instead of the usual electronic components, a beaker containing the oil was placed in the beam. Scintillation light from the oil was detected using a Burle 8850 photomultiplier tube submersed in the oil. This particular photomultiplier tube was chosen because it is capable of detecting single photoelectrons.

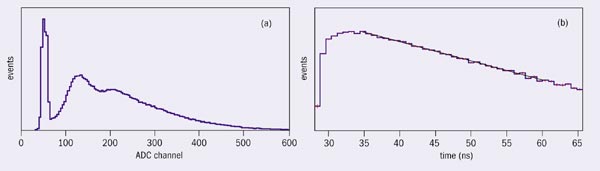

The tests showed that about five photoelectrons are generated per MeV of proton energy loss. The pedestal, the first, and the second photoelectron peaks are visible in figure 1a. A fit to this distribution determines the average number of photoelectrons detected. The time distribution of the scintillation light is well fitted by a single exponential distribution (figure 1b), with a characteristic time of around 19 ns.

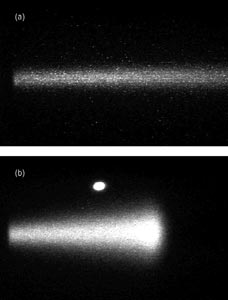

New neutrino detector schemes are also being studied using the RERP facility. During one such test, a small prototype of a liquid scintillation imaging detector was placed in the beam and illuminated with protons. Images of ensembles of protons were obtained using an image-intensifier/CCD camera system. Two of these images are shown in figure 2. Future tests to determine whether single particle tracks can be reconstructed using an array of CCD cameras are planned.

As the size of electronic components continues to decrease into the “nano” regime, the sensitivity of these components to single-event errors increases. Here, the response of certain components to single events triggered by neutrons is particularly interesting. Moreover, neutron scattering is also a valuable tool in materials science, so a low-energy neutron scattering facility (LENS), has been proposed. This would produce copious numbers of neutrons from 11 MeV protons impinging on a production target, and would be accompanied by a neutron irradiation facility (RERPIII). If funding for LENS and RERPIII is granted, the IUCF will be able to provide neutron beams for radiation effects research and materials science by 2005.

Further reading

J Whitmore et al. 2002 Radiation Validation for the CMS HCAL Front-End Electronics. 8th Workshop on Electronics for LHC Experiments (Colmar, France) 433-438 (FERMILAB-CONF-02-224-E).

For more information on the IUCF, see www.iucf.indiana.edu/RERP.