CERN’s vacuum scientists and engineers have completed an intense period of activity during Long Shutdown 2 to prepare the accelerator complex for more luminous operation through LHC Run 3 and beyond. Joe McEntee reports.

The reliability of the CERN vacuum systems is very much front-and-centre as the restart of the LHC physics programme approaches in mid-2022. The near-term priority is the recommencement of beam circulation in vacuum systems that were open to the air for planned interventions and modification – sometimes for several days or weeks – during Long Shutdown 2 (LS2), a wide-ranging overhaul of CERN’s experimental infrastructure that’s been underway since the beginning of 2019.

With LS2 now drawing to a close and pilot beam already circulated in October for a general check of the accelerator chain, it’s worth revisiting the three operational objectives that CERN’s engineering teams set out to achieve during shutdown: consolidation of the LHC dipole diodes (essential safety elements for the superconducting magnets); the anticipation of several interventions required for the High-Luminosity LHC (HL–LHC) project (the successor to the LHC, which will enter operation in 2028); and the LHC Injectors Upgrade project to enhance the injection chain so that beams compatible with HL–LHC expectations can be injected into CERN’s largest machine.

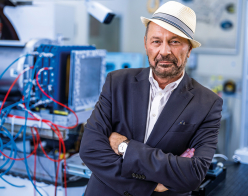

“The CERN vacuum team has made fundamental contributions to the achievement of the LS2 core objectives and other parallel activities,” notes Paolo Chiggiato, head of the CERN vacuum, surfaces and coatings group. “As such, we have just completed an intense period of work in the accelerator tunnels and our laboratories, as well as running and supporting numerous technical workshops.”

As for vacuum specifics, all of the LHC’s arcs were vented to the air after warm-up to room temperature; all welds were leak-checked after the diode consolidation (with only one leak found among the 1796 tests performed); while the vacuum team also replaced or consolidated around 150 turbomolecular pumps acting on the cryogenic insulation vacuum. In total, 2.4 km of non-evaporable-getter (NEG)-coated beampipes were also opened to the air at room temperature – an exhaustive programme of work spanning mechanical repair and upgrade (across 120 weeks), bakeout (spread across 90 weeks) and NEG activation (over 45 weeks). “The vacuum level in these beampipes is now in the required range, with most of the pressure readings below 10–10 mbar,” explains Chiggiato.

Close control

Another LS2 priority for Chiggiato and colleagues involved upgrades to CERN’s vacuum control infrastructure, with the emphasis on reducing single points of failure and the removal of confusing architectures (i.e. systems with no clear separation of function amongst the different programmable logic controllers). “For the first time,” adds Chiggiato, “mobile vacuum equipment was controlled and monitored by wireless technologies – a promising communication choice for distributed systems and areas of the accelerator complex requiring limited stay.”

Elsewhere, in view of the higher LHC luminosity (and consequent increased radioactivity) following LS2 works, the vacuum group developed and installed advanced radiation-tolerant electronics to control 100 vacuum gauges and valves in the LHC dispersion suppressors. This roll-out represents the first step of a longer-term campaign that will be scaled during the next Long Shutdown (LS3 is scheduled for 2025–2027), including the production of 1000 similar electronic cards for vacuum monitoring. “In parallel,” says Chiggiato, “we have renewed the vacuum control software – introducing resilient, easily scalable and self-healing web services technologies and frameworks used by some of the biggest names in industry.”

Success breeds success

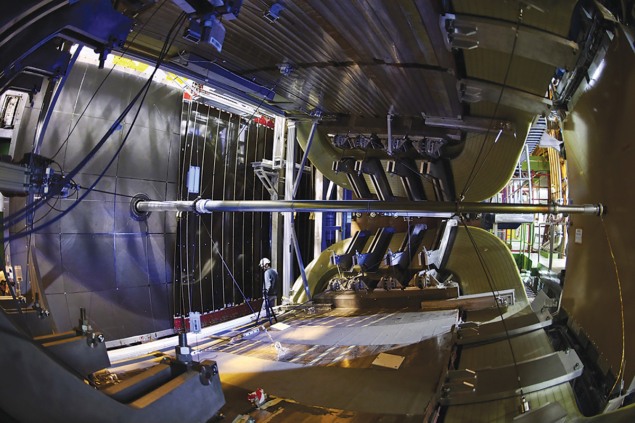

In the LHC experimental area, meanwhile, the disassembly of the vacuum chambers at the beginning of LS2 required 93 interventions and 550 person-hours of work in the equipment caverns. Reinstallation has progressed well in the four core LHC experiments, with the most impressive refit of vacuum hardware in the CMS and LHCb detectors.

For the former, the vacuum team installed a new central beryllium chamber (internal diameter 43.4 mm, 7.3 m long), while 12 new aluminium chambers were manufactured, surface-finished and NEG-coated at CERN. Their production comprised eight separate quality checks, from surface treatment to performance assessment of the NEG coating. “The mechanical installation – including alignments, pump-down and leak detection – lasted two months,” explains Chiggiato, “while the bake-out equipment installation, bake-out process, post-bake-out tests and venting with ultrapure neon required another month.”

Thankfully, creative problem-solving is part of the vacuum team’s DNA

In LHCb, the team contributed to the new version of the Vertex Locator (VELO) sub-detector. The VELO’s job is to pick out B mesons from the multitude of other particles produced – a tricky task as their short lives will be spent close to the beam. To find them, the VELO’s RF box – a delicate piece of equipment filled with silicon detectors, electronics and cooling circuits – must be positioned perilously close to the point where protons collide. In this way, the sub-detector faces the beam at a distance of just 5 mm, with an aluminium window thinned down to 150 μm by chemical etching prior to the deposition of a NEG coating.

As the VELO encloses the RF box, and both volumes are under separate vacuum, the pumpdown is a critical operation because pressure differences across the thin window must be lower than 10 mbar to ensure mechanical integrity. “This work is now complete,” says Chiggiato, “and vacuum control of the VELO is in the hands of the CERN vacuum team after a successful handover from specialists at Nikhef [the Dutch National Institute for Subatomic Physics].”

Wrapping up a three-year effort, the vacuum team’s last planned activity in LS2 involves the bake-out of the ATLAS and CMS beampipe in early 2022. “There was no shortage of technical blockers and potential show-stoppers during our LS2 work programme,” Chiggiato concludes. “Thankfully, creative problem-solving is part of the vacuum team’s DNA, as is the rigorous application of vacuum best practice and domain knowledge accumulated over decades of activity. Ours is a collective mindset, moreover, driven by a humble approach to such complex technological installations, where every single detail can have important consequences.”

A detailed report on the CERN vacuum team’s LS2 work programme – including the operational and technical challenges along the way – will follow in the March/April 2022 issue of CERN Courier magazine.