Development work for the TESLA linear collider has recently made substantial progress. After a surface treatment called electrolytic polishing, four superconducting nine-cell niobium cavities reached accelerating gradients of more than 35 MV/m. This is the performance required for an upgrade of TESLA to 800 GeV.

TESLA is the only linear collider project based on superconducting technology for particle acceleration. The first stage, with a centre-of-mass energy of 500 GeV, will require an accelerating field of 23.4 MV/m in the nine-cell 1.3 GHz superconducting niobium cavities, which are operated at a temperature of 2 K and a quality factor, Q0, of 1010. This performance has been reliably achieved at the TESLA Test Facility (TTF). In the most recent series of 24 industrially produced TTF cavities, the average gradient was 25 ± 2.6 MV/m at Q0 = 1010.

In the TTF cavities a 100-200 µm thick “damage layer” is removed from the inner surface using a chemical etching process called buffered chemical polishing (BCP). The cavities are then subjected to a 1400 °C heat treatment that doubles the thermal conductivity of the niobium at 2 K and increases the gradient by some 5 MV/m. However, after many years of intensive R&D there is now compelling evidence that the BCP process limits the attainable field in multi-cell niobium cavities to about 30 MV/m. This is significantly below the physical limit of about 45 MV/m, which is given by the condition that the radiofrequency (RF) magnetic field must stay below the critical field of the superconductor. For niobium, the maximum tolerable RF field appears to be close to the thermodynamic critical field (190 mT at 2 K).

The upgrade of TESLA to 800 GeV requires an accelerating field of 35 MV/m, which appears inaccessible with the standard cavity preparation technique by BCP. In 1997, however, scientists from KEK reported gradients of up to 40 MV/m in single-cell cavities that had been prepared by electrolytic polishing (EP) of the inner surface. The superiority of electropolishing was then confirmed by an R&D programme on single-cell niobium cavities that was carried out in a collaboration between CERN, DESY and Saclay. These successes motivated a joint KEK-DESY programme on the electropolishing of nine-cell resonators. Meanwhile, nine TTF cavities have been electropolished at the Japanese company Nomura Plating and tested at DESY.

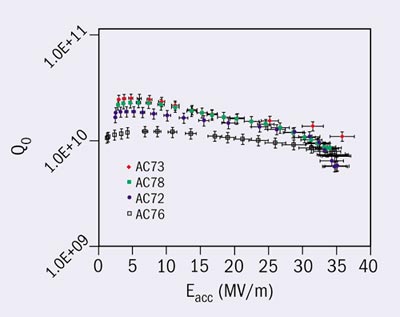

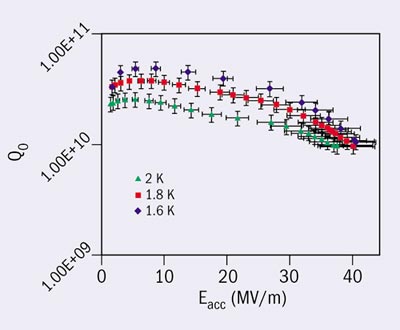

In the low-power test in a vertical superfluid helium cryostat, two of these cavities showed strong field emission at 15-17 MV/m and were therefore taken out for a second electropolishing at DESY. The excitation curves of the four best cavities are shown in figure 1. In November 2003 one of the field-emission loaded cavities was electropolished for a second time in DESY’s new EP facility. The test results of this cavity, shown in figure 2, are excellent: accelerating fields of up to 40 MV/m were reached, a record for multi-cell niobium cavities.

So far, two of the electropolished cavities have been welded into a liquid-helium tank and equipped with a high-power RF coupler, and tests with high RF power have been carried out in a horizontal cryostat at DESY. Both cavities reached the same high gradient as in the low-power test. One cavity was operated for 1100 hours at 35 MV/m and for 57 hours at 36 MV/m without any degradation. These results are clear evidence that the TESLA-800 gradient of 35 MV/m is indeed within reach.

A comprehensive understanding of why EP is so superior to BCP is still lacking, but a few explanations exist. A chemically etched niobium surface has a roughness in the order of micrometres, while an electropolished surface is an order of magnitude smoother. The sharp ridges at the grain boundaries of an etched surface may lead to local enhancements of the RF magnetic field and cause a premature breakdown of superconductivity at these localized spots. A numerical model based on this idea, developed by Jens Knobloch and colleagues at Cornell, can account for the reduction of the quality factor Q0 at high field. Magnetic field enhancements will be much smaller on the smooth electropolished surface.

Another advantage of a mirror-like surface is that a so-called Bean-Livingston surface barrier may exist, delaying the penetration of magnetic flux into the niobium, even if the lower critical field Bc1 (~160 mT for niobium at 2 K) is exceeded. An EP-treated superconducting cavity is likely to remain in the Meissner phase up to an RF magnetic field exceeding Bc1 by a significant amount, whereas a BCP-treated cavity will allow flux penetration just above Bc1, and then suffer from enhanced power dissipation caused by magnetic fluxoids entering and leaving the material.

Further reading

B Aune et al. 2000 Phys. Rev. ST AB 3 092001.

L Lilje et al. 2004 Achievement of 35 MV/m in the Superconducting Nine-Cell Cavities for TESLA NIM A (in press).