Over the past 60 years, GTT has established itself as the technology expert in membrane containment systems for the transport and storage of liquefied gases. In 2023, 511 of the world’s 629 liquefied natural gas carriers with a capacity over 100,000 m³ were equipped with GTT technology. Innovation is at the heart of GTT’s strategy, as demonstrated by its 3295 registered patents and its position as the leading medium-sized company for patent filings in 2023. Today, GTT is applying its expertise to the Deep Underground Neutrino Experiment (DUNE), adapting its advanced solutions to support this groundbreaking scientific research.

The project

DUNE is an international research initiative aimed at enhancing the understanding of neutrinos. It is a dual-site experiment for both neutrino science and proton decay studies. The project utilises neutrinos generated by Fermilab’s Long-Baseline Neutrino Facility (LBNF). Once completed, the LBNF will feature the world’s highest intensity neutrino beam. The infrastructure necessary to support the massive cryogenic far detectors will be installed at the Sanford Underground Research Facility (SURF) 1300 km downstream, in Lead, South Dakota, US. These detectors are housed in large instrumented cryostats filled with liquid argon.

The challenge

The experimental facilities will include several individual cryogenic detectors, each housed inside a large, instrumented cryostat filled with 17,500 tonnes of liquid argon. In this context, the liquid argon must be maintained at a stable temperature of –186°C, requiring perfect tightness, material purity and high thermal insulation. To ensure the proper functioning of the projection chamber and allow electrons to drift over long distances, the impurity of the liquid argon must not exceed 0.1 parts per billion.

The solution

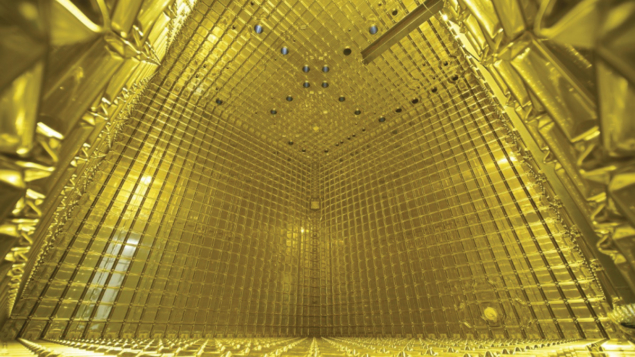

GTT provided a solution based on its technology, which is typically used in cargo ships transporting liquefied natural gas stored at –163°C. GTT’s patented membrane containment system uses two cryogenic envelopes to contain and isolate the liquefied gas. This modular system can be assembled to accommodate large volumes. GTT has offered its services to CERN to provide a solution to the LBNF/DUNE challenge. Each DUNE cryostat is a membrane cryostat constructed with an adapted Mark III membrane containment system developed by GTT.

The Mark III membrane system is a containment and insulation system directly supported by the ship’s hull structure. The containment system consists of a corrugated stainless-steel primary membrane, in contact with the fluid, placed on a prefabricated insulating panel made of reinforced polyurethane foam, incorporating a composite secondary membrane made of Triplex (aluminium foil between two glass cloths). This modular system integrates standard prefabricated components designed to be produced on a large scale and easily assembled –and that can be adapted to any tank shape and capacity.

GTT’s technologies are constantly optimised to meet the expectations of ship-owners and shipyards, its usual market, while complying with changes in maritime regulations. Since 2008, GTT has been working on developments of the Mark III concept, dedicated to improving the thermal and structural efficiency of the technology. In 2011, GTT launched the Mark III Flex technology, an improved version of Mark III, which offers a guaranteed boil-off rate of 0.07% volume/day, thanks to an increased thickness of 480 mm.

Why not extend this technology to another field? GTT and CERN have collaborated since 2013 to tailor GTT’s technology to CERN’s requirements, focusing on thermal performance and the containment of ultra-pure liquid argon for the time projection chambers required for DUNE. Leveraging the adaptability of the Mark III system, GTT has designed six tanks with CERN, resulting in a fully tested technology that meets CERN’s requirements. The collaboration began with a 17m³ initial prototype commissioned in 2017, followed by two 600m³ tanks, ProtoDUNE, commissioned in 2018 and 2019. The design showed areas for further improvement and required specific upgrades.

Following this initial set of prototypes, CERN and GTT worked together to propose an improved design. This design, optimised for cryogenic conditions, offers excellent containment tightness and thermal insulation, which helps maintain argon purity. The adapted technology includes:

• approximately 800 mm of insulation thickness;

• specific panel arrangements;

• double containment;

• tightness ensured by a combination of stainless steel (1.2 mm) for the primary barrier, a composite material (0.7 mm) for the secondary barrier and a reinforced polyurethane foam for insulation.

This optimised design has been tested and commissioned for two tanks so far. The first, a 200m³ short-baseline near detector sitting in the Booster Neutrino Beam at Fermilab, was commissioned in January 2023, and the second, a 600m³ dark side tank at the Gran Sasso National Laboratory in Assergi, Italy, was commissioned in June 2024.

The future

In the coming years, CERN and GTT will continue their collaboration with future targets already identified. The construction of two tanks, each with a capacity of 12,500 m³, for the DUNE far detector cryostats, to be installed at SURF in Lead, 1300 km downstream, will be the pinnacle of this collaboration. The design of the containment system has been completed by GTT, and the start of construction is planned for 2025.