The RD51 collaboration has provided important stimulus for growth in the development of MPGDs.

Résumé

RD51 et l’essor des détecteurs gazeux à micropistes

En 2008 a été créée au CERN la collaboration RD51, répondant ainsi au besoin de développer et d’utiliser les techniques innovantes des détecteurs gazeux à micropistes (MPGD). Si nombre de ces technologies ont été adoptées avant la création de RD51, d’autres techniques sont apparues depuis ou sont devenues accessibles, de nouveaux concepts de détection sont en cours d’adoption et des techniques actuelles font l’objet d’améliorations importantes. Parallèlement, le déploiement de détecteurs MPGD dans des expériences en exploitation s’est considérablement accru. Aujourd’hui, RD51 est au service d’une vaste communauté d’utilisateurs, veillant sur le domaine des détecteurs MPGD et sur les applications commerciales qui pourraient voir le jour.

Image credits: RD51 Collaboration.

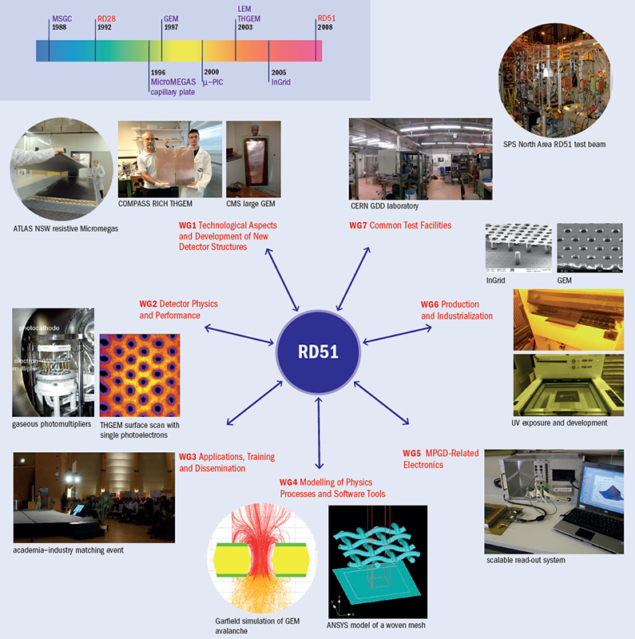

Improvements in detector technology often come from capitalizing on industrial progress. Over the past two decades, advances in photolithography, microelectronics and printed circuits have opened the way for the production of micro-structured gas-amplification devices. By 2008, interest in the development and use of the novel micro-pattern gaseous detector (MPGD) technologies led to the establishment at CERN of the RD51 collaboration. Originally created for a five-year term, RD51 was later prolonged for another five years beyond 2013. While many of the MPGD technologies were introduced before RD51 was founded (figure 1), with more techniques becoming available or affordable, new detection concepts are still being introduced, and existing ones are substantially improved.

In the late 1980s, the development of the micro-strip gas chamber (MSGC) created great interest because of its intrinsic rate-capability, which was orders of magnitude higher than in wire chambers, and its position resolution of a few tens of micrometres at particle fluxes exceeding about 1 MHz/mm2. Developed for projects at high-luminosity colliders, MSGCs promised to fill a gap between the high-performance but expensive solid-state detectors, and cheap but rate-limited traditional wire chambers. However, detailed studies of their long-term behaviour at high rates and in hadron beams revealed two possible weaknesses of the MSGC technology: the formation of deposits on the electrodes, affecting gain and performance (“ageing effects”), and spark-induced damage to electrodes in the presence of highly ionizing particles.

These initial ideas have since led to more robust MPGD structures, in general using modern photolithographic processes on thin insulating supports. In particular, ease of manufacturing, operational stability and superior performances for charged-particle tracking, muon detection and triggering have given rise to two main designs: the gas electron-multiplier (GEM) and the micro-mesh gaseous structure (Micromegas). By using a pitch size of a few hundred micrometres, both devices exhibit intrinsic high-rate capability (> 1 MHz/mm2), excellent spatial and multi-track resolution (around 30 μm and 500 μm, respectively), and time resolution for single photoelectrons in the sub-nanosecond range.

Coupling the microelectronics industry and advanced PCB technology has been important for the development of gas detectors with increasingly smaller pitch size. An elegant example is the use of a CMOS pixel ASIC, assembled directly below the GEM or Micromegas amplification structure. Modern “wafer post-processing technology” allows for the integration of a Micromegas grid directly on top of a Medipix or Timepix chip, thus forming integrated read-out of a gaseous detector (InGrid). Using this approach, MPGD-based detectors can reach the level of integration, compactness and resolving power typical of solid-state pixel devices. For applications requiring imaging detectors with large-area coverage and moderate spatial resolution (e.g. ring-imaging Cherenkov (RICH) counters), coarser macro-patterned structures offer an interesting economic solution with relatively low mass and easy construction – thanks to the intrinsic robustness of the PCB electrodes. Such detectors are the thick GEM (THGEM), large electron multiplier (LEM), patterned resistive thick GEM (RETGEM) and the resistive-plate WELL (RPWELL).

RD51 and its working groups

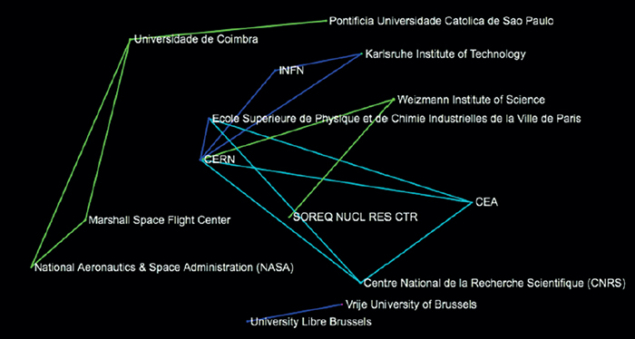

The main objective of RD51 is to advance the technological development and application of MPGDs. While a number of activities have emerged related to the LHC upgrade, most importantly, RD51 serves as an access point to MPGD “know-how” for the worldwide community – a platform for sharing information, results and experience – and optimizes the cost of R&D through the sharing of resources and the creation of common projects and infrastructure. All partners are already pursuing either basic- or application-oriented R&D involving MPGD concepts. Figure 1 shows the organization of seven Working Groups (WG) that cover all of the relevant aspects of MPGD-related R&D.

WG1 Technological Aspects and Development of New Detector Structures. The objectives of WG1 are to improve the performance of existing detector structures, optimize fabrication methods, and develop new multiplier geometries and techniques. One of the most prominent activities is the development of large-area GEM, Micromegas and THGEM detectors. Only one decade ago, the largest MPGDs were around 40 × 40 cm2, limited by existing tools and materials. A big step towards the industrial manufacturing of MPGDs with a size around a square metre came with new fabrication methods – the single-mask GEM, “bulk” Micromegas, and the novel Micromegas construction scheme with a “floating mesh”. While in “bulk” Micromegas, the metallic mesh is integrated into the PCB read-out, in the “floating-mesh” scheme it is integrated in the panel containing drift electrodes and placed on pillars when the chamber is closed. The single-mask GEM technique overcomes the cumbersome practice of alignment of two masks between top and bottom films, which limits the achievable lateral size to 50 cm. This technology, together with the novel “self-stretching technique” for assembling GEMs without glue and spacers, simplifies the fabrication process to such an extent that, especially for large-volume production, the cost per unit area drops by orders of magnitude.

Another breakthrough came with the development of Micromegas with resistive electrodes for discharge mitigation. The resistive strips match the pattern of the read-out strips geometrically, but are electrically insulated from them. Large-area resistive electrodes to prevent sparks have been developed using two different techniques: screen printing and carbon sputtering. The technology of the THGEM detectors is well established in small prototypes, the major challenge is the industrial production of high-quality large-size boards. A novel MPGD-based hydrid architecture, consisting of double THGEM and Micromegas, has been developed for photon detection; the latter allows a significant reduction in the ion backflow to the photocathode. A spark-protected version of THGEM (RETGEM), where the copper-clad conductive electrodes are replaced by resistive materials, and the RPWELL detector, consisting of a single-sided THGEM coupled to the read-out electrode through a sheet of large bulk resistivity, have also been manufactured and studied. To reduce discharge probability, a micro-pixel gas chamber (μ-PIC) with resistive electrodes using sputtered carbon has been developed; this technology is easily extendable for the production of large areas up to a few square metres.

To reduce costs, further work is needed for developing radiation-hard read-out and reinventing mainstream technologies under a new paradigm of integration of electronics and detectors, as well as integration of functionality, e.g. integrating read-out electronics directly into the MPGD structure. A breakthrough here is the development of a time-projection chamber (TPC) read-out with a total of 160 InGrid detectors, each 2 cm2, corresponding to 10.5 million pixels. Despite the enormous challenges, this has demonstrated for the first time the feasibility of extending the Timepix CMOS read-out of MPGDs to large areas.

Image credit: Collaboration Spotting/ collspotting.web.cern.ch.

WG2 Detector Physics and Performance. The goal of WG2 is to improve understanding of the basic physics phenomena in gases, to define common test standards, which allow comparison and eventually selection among different technologies for a particular application, and to study the main physics processes that limit MPGD performance, such as sparking, charging-up effects and ageing.

Primary ionization and electron multiplication in avalanches are statistical processes that set limits to the spatial, energy and timing resolution, and so affect the overall performance of a detector. Exploiting the ability of Micromegas and GEM detectors to measure both the position and arrival time of the charge deposited in the drift gap, a novel method – the μTPC – has been developed for the case of inclined tracks, allowing for a precise segment reconstruction using a single detection plane, and significantly improving spatial resolution (well below 100 μm, even at large track angles). Excellent energy resolution is routinely achieved with “microbulk” Micromegas and InGrid devices, differing only slightly from the accuracy obtained with gaseous scintillation proportional counters and limited by the Fano factor. Moreover, “microbulk” detectors have very low levels of intrinsic radioactivity. Other recent studies have revealed that Micromegas could act as a photodetector coupled to a Cherenkov-radiator front window, in a set-up that produces a sufficient number of UV photons to convert single-photoelectron time jitter of a few hundred picoseconds into an incident-particle timing response of the order of 50 ps.

One of the central topics of WG2 is the development of effective protection against discharges in the presence of heavily ionizing particles. The limitation caused by occasional sparking is now being lifted by the use of resistive electrodes, but at the price of current-dependent charging-up effects that cause a reduction in gain. Systematic studies are needed to optimize the electrical and geometrical characteristics of resistive Micromegas in terms of the maximum particle rate. Recent ageing studies performed in view of the High-Luminosity LHC upgrades confirmed that the radiation hardness of MPGDs is comparable with solid-state sensors in harsh radiation environments. Nevertheless, it is important to develop and validate materials with resistance to ageing and radiation damage.

Many of the advances involve the use of new materials and concepts – for example, a GEM made out of crystallized glass, and a “glass piggyback” Micromegas that separates the Micromegas from the actual read-out by a ceramic layer, so that the signal is read by capacitive coupling and the read-out is immune to discharges. A completely new approach is the study of charge-transfer properties through graphene for applications in gaseous detectors.

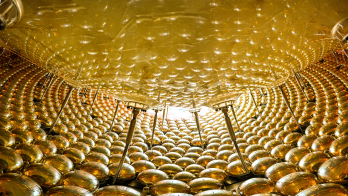

Working at cryogenic temperatures – or even within the cryogenic liquid itself – requires optimization to achieve simultaneously high gas gain and long-term stability. Two ideas have been pursued for future large-scale noble-liquid detectors: dual-phase TPCs with cryogenic large-area gaseous photomultipliers (GPMs) and single-phase TPCs with MPGDs immersed in the noble liquid. Studies have demonstrated that the copious light yields in liquid xenon, and the resulting good energy resolution, are a result of electroluminescence occurring within xenon-gas bubbles trapped under the hole electrode.

WG3 Applications, Training and Dissemination. WG3 concentrates on the application of MPGDs and on how to optimize detectors for particularly demanding cases. Since the pioneering use of GEM and Micromegas by the COMPASS experiment at CERN – the first large-scale use of MPGDs in particle physics – they have spread to colliders. Their use in mega-projects at accelerators is very important to engage people with science and to receive public recognition. During the past five years, there have been major developments of Micromegas and GEMs for various upgrades for ATLAS, CMS and ALICE at the LHC, as well as THGEMs for the upgrade of the COMPASS RICH. Although normally used as flat detectors, MPGDs can be bent to form cylindrically curved, ultralight tracking systems as used in inner-tracker and vertex applications. Examples are cylindrical GEMs for the KLOE2 experiment at the DAFNE e+e– collider and resistive Micromegas for CLAS12 at Jefferson Lab. MPGD technology can also fulfil the most stringent constraints imposed by future facilities, from the Facility for Antiproton and Ion Research to the International Linear Collider and Future Circular Collider.

MPGDs have also found numerous applications in other fields of fundamental research. They are being used or considered, for example, for X-ray and neutron imaging, neutrino–nucleus scattering experiments, dark-matter and astrophysics experiments, plasma diagnostics, material sciences, radioactive-waste monitoring and security applications, medical physics and hadron therapy.

To help in further disseminating MPGD applications beyond fundamental physics, academia–industry matching events were introduced when the continuation of the RD51 was discussed in 2013. Since then, three events have been organized by RD51 in collaboration with the HEPTech network (CERN Courier April 2015 p17), covering MPGD applications in neutron and photon detection. The events provided a platform where academic institutions, potential users and industry could meet to foster collaboration with people interested in MPGD technology. In the case of neutron detection, there is tangible mutual interest between the high-energy physics and neutron-scattering communities to advance the technology of MPGDs; GEM-based solutions for thermal-neutron detection at spallation sources, novel high-resolution neutron devices for macromolecular crystallography, and fast neutron MPGD detectors in fusion research represent a new frontier for future developments.

WG4 Modelling of Physics Processes and Software Tools. Fast and accurate simulation has become increasingly important as the complexity of instrumentation has increased. RD51’s activity on software tools and the modelling of physics processes that make MPGDs function provides an entry point for institutes that have a strong theoretical background, but do not yet have the facilities to do experimental work. One example is the development of a nearly exact boundary-element solver, which is in most aspects superior to the finite-element method for gas-detector simulations. Another example is the dedicated measurement campaign and data analysis programme that was undertaken to understand avalanche statistics and determine the Penning transfer-rates in numerous gas mixtures.

Image credit: Collaboration Spotting/ collspotting.web.cern.ch.

The main difference between traditional wire-based devices and MPGDs is that the electrode size of order 10 μm in MPGDs is comparable to the collision mean free path. Microscopic tracking algorithms (Garfield++) developed within WG4 have shed light on the effects of surface and space charge in GEMs, as well as on the transparency of meshes in Micromegas. The microscopic tracking technique has also led to better understanding of the avalanche-size statistics, clarifying in particular why light noble gases perform better than heavier noble gases. Significant effort has also been devoted to modelling the performance of MPGDs for particular applications – for example, studies of electron losses in Micromegas with different mesh specifications, and of GEM electron transparency, charging-up and ion-backflow processes, for the ATLAS and ALICE upgrades.

WG5 MPGD-Related Electronics. Initiated in WG5 in 2009 as a basic multichannel read-out-system for MPGDs, the scalable read-out system (SRS) electronics has evolved into a popular RD51 standard for MPGDs. Many groups contribute to SRS hardware, firmware, software and applications, and the system has already extended beyond RD51. SRS is generally considered to be an “easy-to-use” portable system from detector to data analysis, with read-out software that can be installed on a laptop for small laboratory set-ups. Its scalability principle allows systems of 100,000 channels and more to be built through the simple addition of more electronic SRS slices, and operated at very high bandwidth using the online software of the LHC experiments. The front-end adapter concept of SRS represents another degree of freedom, because basically any sensor technology typically implemented in multi-channel ASICs may be used. So far, five different ASICs have been implemented on SRS hybrids as plug-ins for MPGDs: APV25, VFAT, Beetle, VMM2 and Timepix.

The number of SRS systems deployed is now nearing 100, with more than 300,000 APV channels, corresponding to a total volume of SRS sales of around CHF1 million. SRS has been ported for the read-out of photon detectors and tracking detectors, and is being used in several of the upgrades for ALICE, ATLAS, CMS and TOTEM at the LHC. Meanwhile, CERN’s Technology Transfer group has granted SRS reproduction licences to several companies. Since 2013, SRS has been re-designed according to the ATCA industry standard, which allows for much higher channel density and output bandwidth.

WG6 Production and Industrialization. A key point that must be solved in WG6 to advance cost-effective MPGDs is the manufacturing of large-size detectors and their production by industrial processes. The CERN PCB workshop is a unique MPGD production facility, where generic R&D, detector-component production and quality control take place. Today, GEM and Micromegas detectors can reach areas of 1 m2 in a single unit and nearly 2 m2 by patching some elements inside the detectors. Thanks to the completion of the upgrade to its infrastructure in 2012, CERN is still leading in the MPGD domain in terms of maximum detector size; however, more than 10 companies are already producing detector parts of reasonable size. WG6 serves as a reference point for companies interested in MPGD manufacturing and helps them to reach the required level of competences. Contacts with some have strengthened to the extent that they have signed licence agreements and engaged in a technology-transfer programme co-ordinated within WG6. As an example, the ATLAS New Small Wheel (NSW) upgrade will be the first detector mass produced in industry using a large high-granularity MPGD, with a detecting area around 1300 m2 divided into 2 m × 0.5 m detectors.

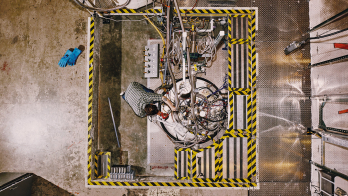

WG7 Common Test Facilities. The development of robust and efficient MPGDs entails understanding of their performance and implies a significant investment for laboratory measurements and detector test-beam activities to study prototypes and qualify final designs. Maintenance of the RD51 lab at CERN and test-beam facilities plays a key role among the objectives of WG7. A semi-permanent common test-beam infrastructure has been installed at the H4 test-beam area at CERN’s Super Proton Synchrotron for the needs of the RD51 community. It includes three high-precision beam telescopes made of Micromegas and GEM detectors, data acquisition, services, and gas-distribution systems. One advantage of the H4 area is the “Goliath” magnet (around 1.5 T over a large area), allowing tests of MPGDs in a magnetic field. RD51 users can also use the instrumentation, services and infrastructures of the Gas Detector Development (GDD) laboratory at CERN, and clean rooms are accessible for assembly, modification and inspection of detectors. More than 30 groups use the general RD51 infrastructure every year as a part of the WG7 activities; three annual test-beam campaigns attract on average three to seven RD51 groups at a time, working in parallel.

The RD51 collaboration also advances the MPGD domain with scientific, technological and educational initiatives. Thanks to RD51’s interdisciplinary and inter-institutional co-operation, the University Antonio Nariño in Bogota has built a detector laboratory where doctoral students and researchers are trained in the science and technology of MPGDs. With this new infrastructure and international support, the university is leveraging co-operation with other Latin American institutes to build a critical mass around MPGDs in this part of the world.

Given the ever-growing interest in MPGDs, RD51 re-established an international conference series on the detectors. The first meeting in the new series took place in Crete in 2009, followed by Kobe in 2011 and Zaragoza in 2013 (CERN Courier November 2013 p33). This year, the collaboration is looking forward to holding the fourth MPGD conference in Trieste, on 12–15 October.

The vitality of the MPGD community resides in the relatively large number of young scientists, so educational events constitute an important activity. A series of specialized schools, comprising lectures and hands-on training for students, engineers and physicists from RD51 institutes, has been organized at CERN covering the assembly of MPGDs (2009), software and simulation tools (2011), and electronics (2014). This is particularly important for young people who are seeking meaningful and rewarding work in research and industry. Last year, RD51 co-organized the MPGD lecture series and the IWAD conference in Kolkata, the Danube School on Instrumentation in Novi Sad, and the special “Charpak Event” in Lviv, organized in the context of CERN’s 60th anniversary programme “60 Years of Science for Peace” (CERN Courier November 2014 p38). The latter was organized at a particularly fragile time for Ukraine, to enhance the role of science diplomacy to tackle global challenges via the development of novel technologies.

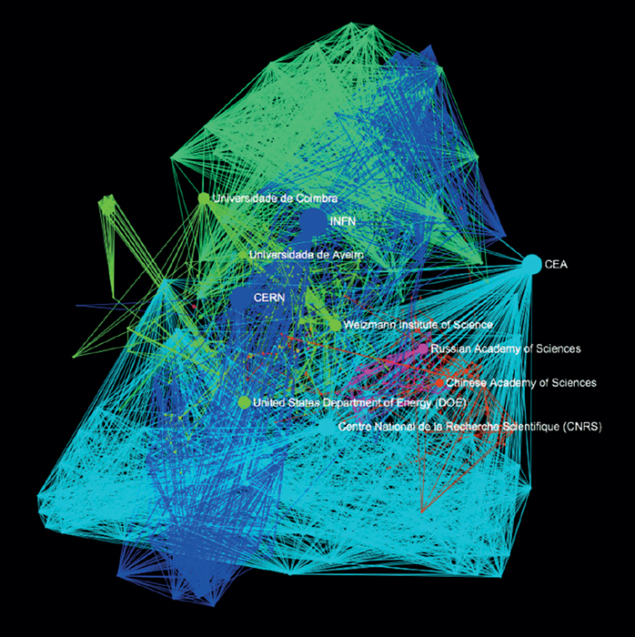

In conclusion

During the past 10 years, the deployment of MPGDs in operational experiments has increased enormously, and RD51 now serves a broad user community, driving the MPGD domain and any potential commercial applications that may arise. Because of a growing interest in the benefits of MPGDs in many fields of research, technologies are being optimized for a broad range of applications, demonstrating the capabilities of this class of detector. Today, RD51 is continuing to grow, and now has more than 90 institutes and 450 participants from more than 30 countries in Europe, America, Asia and Africa. Last year, six new institutes from Spain, Croatia, Brazil, Korea, Japan and India joined the collaboration, further enhancing the geographical diversity and expertise of the MPGD community. Since its foundation, RD51 has provided a fundamental boost from isolated developers to a world-wide MPGD network, as illustrated by collaboration-spotting software (figure 2, p29). Many opportunities are still to be exploited, and RD51 will remain committed to the quest to help shape the future of MPGD technologies and pave the way for novel applications.

• For more information about RD51, visit http://rd51-public.web.cern.ch/RD51-Public/.