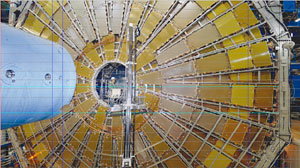

A look at the huge endcap systems for the ATLAS muon spectrometer.

During the 1990s, visitors to the experiments at LEP were usually impressed by their size and complexity and, in particular, how different subsystems constructed in a variety of different countries could fit together. The LHC has now usurped LEP, and this impression has also been replaced by either a scream or complete silence, as visitors to the experiments are overwhelmed by the size and complexity. These differences can be clearly seen by comparing the same type of detector – thin gap chambers (TGCs) – as used for calorimetry and electron identification in the OPAL experiment at LEP (figure 1) with those used for the muon trigger in the ATLAS endcaps, in part of the system known as the ATLAS Big Wheels (figure 2).

Image credit: Keystone/Science Photo Library/David Parker.

The reason for this big change is that, while for the LEP experiments every collision was of interest, at the LHC only one collision in 10 million will be kept for further analysis. In particular, high-momentum muons constitute an important element in defining which events should be kept. For this reason the ATLAS Collaboration decided to construct a large muon spectrometer, based on superconducting air toroids, which allows the precise measurement of muon momenta down to small angles with respect to the proton beam direction.

The ATLAS muon wheels are a system of 10 movable and two fixed “wheels” of muon detectors grouped at three stations in each of the two endcaps of the ATLAS detector. The fixed wheels are outermost at each end, while the intermediate stations of big wheels are located just outside the endcap toroid magnet and the edges of the coils of the barrel toroid, and the inner stations of two small wheels lie between the endcap toroids and the calorimeter (figure 3).

Each intermediate station consists of four big wheels with a diameter of 25 m, which are formed from a number of sectors built using different types of muon chamber. The wheels can be moved longitudinally along the direction of the beamline in order to gain access to the central part of ATLAS for the purposes of installation and maintenance. At each end of the barrel, three wheels are used to trigger on high-momentum muons, while one wheel provides a measurement of their trajectories in the bending plane with a precision of a fraction of the width of a human hair. The construction of such large devices was too ambitious a project for a single institution or country, so international collaborations were formed within ATLAS that ran across countries, cultures and religions, and where motivation played a cohesive role.

There are almost 1500 trigger modules on the six trigger big wheels and these were built by a collaboration between China, Israel and Japan. They are formed from TGCs, which are read out in two dimensions through wires and strips. These detectors, based on the technology used in the OPAL experiment, are constructed from lightweight composite materials combined with four million gold-plated tungsten wires. Three custom-built laboratories were made available for their construction at Shandong University, KEK and the Weizmann Institute.

The TGCs are fast and accurate enough to provide a selective trigger, which combined with the trigger electronics designed and constructed in Japan, is capable of identifying muons with large transverse momentum and to associate them with a specific bunch crossing of the LHC, occurring at a frequency of 40 MHz. The measurement of muon tracks in the non-bending plane (along an approximately azimuthal direction) is necessary for the ultimate determination of muon momenta by the chambers in the precision wheel that accompanies each set of trigger wheels.

The TGC units underwent a long series of quality-control tests. In particular, every detector was scanned with cosmic muons in one of three different laboratories (Kobe, Technion and Tel Aviv) to ensure a high uniformity of response. The majority of the detectors were also exposed to a 3 kCi 60Co source for half an hour, and finally, after transportation to CERN, they were operated for three weeks, to avoid early breakdown. This series of tests resulted in a failure rate of 1 in 1000 after the detectors were mounted on the frames. The two failed chambers were then replaced by spares.

The two precision big wheels are equipped with monitored drift tubes (MDTs), which are also present in all other stations in the endcap and in the barrel regions of the spectrometer. These detectors, developed and constructed for the ATLAS muon spectrometer by a collaboration of many institutes from Europe, Russia, the US and China, are based on drift tubes with a diameter of 3 cm and various lengths. The MDTs are arranged in two multilayers and operated at a pressure of 3 bar. They measure muon tracks with a precision of some 40 μm.

The accuracy of the spectrometer is fully exploited with a complex alignment system jointly designed and implemented by groups from France, Germany, Holland and the US. Optical devices mounted on all detectors and on reference components installed on each station of the spectrometer are capable of establishing the relative alignment of towers of detectors with a precision of about 40 μm. The system is used to correct for offsets from the nominal positions, and also for mechanical deformations induced in detectors and support structures by gravity, magnetic fields and temperature variations. These effects are small compared with the dimensions of the structures, but they may be significant on the scale of the precision of the detectors.

The 160 MDT chambers in the two precision big wheels were constructed in three production centres in the US. They are formed from a total of nearly 61,000 drift tubes, with lengths ranging from 0.8 m near the centre to 5.7 m near the outer boundary, where the largest chambers measure 1.9 × 6.0 m2. The alignment system in the precision big wheels was constructed by a collaboration of US and German institutes, and it exploits eight calibrated bars installed on each wheel and equipped with optical devices.

All of the MDT chambers were the subject of an extensive series of tests before and after shipment to CERN, including checks of gas tightness, dark current and noise, followed by a full chamber scan using cosmic muons. The geometrical accuracy in the construction of the detectors was tested at the production sites by various methods, and by a direct measurement performed on a sample of chambers in a dedicated X-ray tomograph facility at CERN.

Image credit: ATLAS Collaboration.

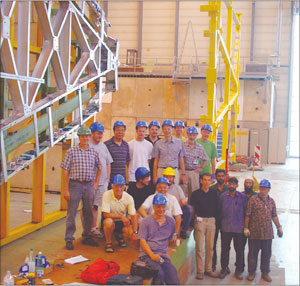

The assembly and commissioning of the 104 sectors forming the eight big wheels was a complex and intensive activity. This took place on the Meyrin site at CERN from spring 2005 to July 2007. The relatively light support structures were designed at CERN, following an initial study carried out in Russia, and they were manufactured in Israel and Russia. The assembly was performed in four working areas, and several teams contributed to the different tasks of mechanical assembly (teams from Pakistan, using assembly jigs that had been manufactured in Pakistan, together with a team from Israel), installation of services and detectors (teams from China/Israel and the US), tests of detectors and trigger electronics (Japan/Israel and the US), and engineering, survey, handling and general coordination (CERN, with the contribution of a team from JINR-Dubna). The tests performed covered all aspects of the detectors and their read-out and control systems, and they included the use of radioactive sources and cosmic rays. Out of a total of 430,000 TGC and MDT read-out channels, the number of non-operational channels was found to be at the level of a few in 10,000.

Image credit: ATLAS Collaboration.

From July 2006 to September 2007, one by one the sectors were transported to Point 1 for installation in the ATLAS cavern. Sectors were then mounted against the end walls of the hall and connected to each other to form the wheels (figure 6). The mechanical accuracy of about 1 mm achieved in the construction of the sectors was essential for the smooth and fast assembly of the wheels, which was coordinated by engineers from CERN and performed by teams of the ATLAS Technical Coordination. Absolute positions of the various detectors were measured by the CERN surveying team, using photogrammetry, making it the first time that such methods had been used for such large surfaces. Alignment systems were available to confirm the assembly accuracy and the stability of the wheels when supported on two points and moved on rails. Moving the wheels was itself an exciting operation, dealing with flexible disks of about 30 tonnes in weight, 25 m diameter and as thin as 30 cm.

Following installation the full commissioning of the big wheels has progressed well, with the connection of services and integration in the read-out and in the trigger systems being completed in spring 2008. Data from both trigger and precision chambers in the muon endcaps have been available in the combined cosmic runs of the muon spectrometer and ATLAS since summer 2007. Figure 7 shows an example of a cosmic muon track recorded in the big wheels during one of the cosmic runs.

The endcap region of the ATLAS muon spectrometer has also been completed recently with the inner stations of small wheels. For the fixed wheels in the outer station, which consist of precision chambers, most of the detectors were present by December 2007. Final installation should soon be completed together with the beam-pipe and the shielding of the endcap region, as the ATLAS collaboration prepares for the first beams of the LHC.