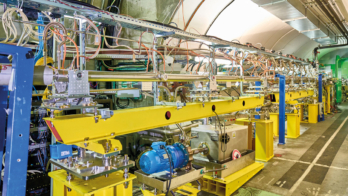

The LHC, with its “two in one” magnet structure cooled by superfluid helium for operation at 1.9 K, is its own prototype. It is therefore no surprise that problems arise that demand ingenious solutions, such as a newly invented diagnostic tool. Slightly larger than a ping-pong ball, it contains a tiny 40 MHz transmitter and fits just inside the beam pipe. Its purpose is to check interconnections within a sector (an eighth) of the machine without the need to open it up.

The need for such a device came to light when teams detected a fault in one of the interconnections during the warm-up of sector 7-8, the first to have been cooled to 1.9 K. One of the “plug in” modules responsible for the continuity of the electrical circuit in each of the LHC’s two vacuum chambers was damaged as the sector warmed up.

The plug-in modules ensure that mirror currents produced by the beams in the walls of the vacuum chambers can circulate freely. Any impedance would create hot points and reduce the intensity of the beam. The modules consist of copper “fingers” that slide along a cylinder and allow for contraction and expansion of the LHC’s components during cooling and warming. Each module expands or shrinks by about 40 mm, but the fingers always remain in contact with the cylinder in which they are sliding. In the faulty unit, the fingers failed to slide properly when the vacuum pipes returned to their original length, buckling into the space where the beam would normally pass.

It is difficult and time-consuming to open the magnet cryostats to check interconnections; it takes three weeks to open a sector and five weeks to close it again. X-ray studies revealed four more faulty modules in sector 7-8, but it was clear that a device that could check the space inside the beam pipes would be extremely useful. The solution is a ball 34 mm in diameter, which transmits at 40 MHz – the frequency of beam bunches in the LHC. A pumping system propels it through the vacuum pipe and beam-position monitors located every 50 m pick up the emitted signals. As the ball is a fraction smaller than the 36 mm beam screen, any obstacles will stop its progress and there will be no signal in the next monitor. This information allows the team to concentrate on the small number of interconnections between the two beam-position monitors concerned.

A first test on 13 September proved successful as the ball travelled 800 m through one vacuum pipe, detecting a sixth faulty module in the process. Altogether, only 6 out of 366 modules have proved to be damaged as sector 7-8 warmed up, and repairs are now in progress. An extra benefit is that the device allows the team to inspect the beam pick-ups around the ring.

Elsewhere around the LHC, by the end of October teams had cooled a second sector to 80 K and begun pressure testing on a third. Any vacuum leaks that were found have been isolated and are currently being repaired. Cooling of further sectors should begin in November.

In addition, all of the inner triplet magnet assemblies have been repaired and are in position in the tunnel. Three of them had passed their pressure tests by the beginning of October. The cryogenic electrical distribution feedboxes (DFBX), which form part of the triplet assembly, have also undergone repairs. Only the triplet that was damaged during the spring test, plus one DFBX, have been removed from the tunnel. The others have been repaired in situ, a prerequisite for a solution.