The reliability of the LHC will depend not only on the superconducting magnets but also on the interconnections between magnetic sections, as Blazej Skoczen explains.

The classic “FODO lattice” – the basic combination of magnets that is repeated around the ring of most modern synchrotrons – contains not only focusing/defocusing magnets (main quadrupoles) and bending magnets (main dipoles) but also drift spaces between the magnets where the particles simply coast. These drift zones fulfil a very fundamental function, providing space for all the necessary connections for the beam chambers and power supplies, and also for the cryogenic systems, thermal shielding and vacuum vessels in the case of superconducting machines such as the Large Hadron Collider (LHC). However, because the drift space does not provide beam bending strength, it is wasted space in terms of achieving the highest beam energy in the ring. So one of the design requirements for circular accelerators and storage rings that are optimized for high beam energy is to minimize the ratio of drift-to-magnetic length in the machine arcs. This implies strong constraints on the systems located in the drift spaces, such as the thermal contraction/expansion compensation system, the radiofrequency (RF) contacts between the beam screens, the joints of the superconducting bus-bars, etc.

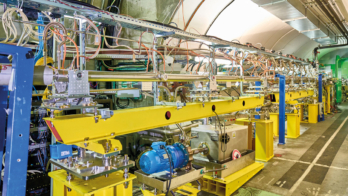

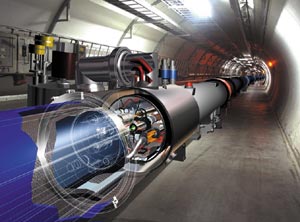

In the LHC, despite the machine’s complexity, the interconnections have been optimized to the extent that they will occupy only 3.7% of the accelerator length in the arcs and associated dispersion suppressors. (The machine consists of eight bending arcs, generally with dispersion suppressor sections located at either end of the arc to reduce the horizontal dispersion in the beams.) Figures 1 and 2 show the crowded interconnection region planned for the final machine and as already implemented in a prototype.

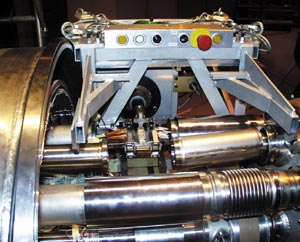

Such an achievement has had its price, however. As a result of a tight mathematical optimization, the components of the thermal contraction/expansion compensation system – the expansion bellows, which are composed of very thin corrugated shells (figure 3) – have been pushed to operate beyond the elastic limit, where plastic deformation occurs. Thus, for the first time in the history of accelerators, the interconnection bellows “plastify” with every cycle of cool-down (to 1.9 K) and warm-up (back to 293 K), whereas the magnets stay “elastic”. This process is associated with the evolution of plastic strain fields in the “concertina” of the bellows convolutions, which is accompanied by micro-damage and, at low temperatures, a strain-induced phase transformation (from a face-centred-cubic to a body-centred-cubic material structure). To minimize the intensity of this phase transformation, the bellows convolutions are made from a special “medical” grade of stainless steel. Figure 4 shows typical hysteresis curves, indicating the dissipation of energy due to plastic deformation during cycling between room and low temperatures. To obtain a reliable performance of the expansion bellows, these phenomena were all carefully modelled and tested at room and cryogenic temperatures. As the number of these components in the LHC exceeds 20,000, a statistical check of their reliability is performed, based on accelerated life testing of 1% of the components.

Another important feature of the interconnection zones concerns the joints between the superconductors. These joints, or splices, comprise connections both between the Rutherford-type superconducting cables powering the main magnets and between the small superconducting bus-bars that power the corrector magnets (figure 5). Each joint contains two overlapping superconductors separated by a strip of Sn96Ag4 or a thin layer of copper (depending on the joining technology), so the dissipation of energy due to heating losses is localized in this non-superconducting layer. While typical resistances of the joints between Rutherford-type superconductors remain below 0.6 nΩ at 1.9 K, the joints located in the corrector circuits show some 3 nΩ of resistance. Given the total number of joints, the maximum dissipation of energy per interconnection zone (if all systems are simultaneously powered) amounts to around 670 mW at 1.9 K (in a dipole-quadrupole interconnection). Thus a large fraction of the total energy dissipated at low temperatures into the coolant (superfluid helium) is localized in the electrical interconnections between the main LHC magnets, and the amount of energy that can be “produced” in the interconnections in this way is severely limited by the thermodynamic budget of the LHC.

In view of the severity of the various criteria that the LHC interconnections must satisfy, a rigorous reliability analysis is a must. The target set for the availability of all the LHC interconnections (around 1700 zones) is based on the assumption of at most one short intervention (10.5 days) per 10 years of LHC operation. This ambitious goal implies that the availability of the LHC interconnections for the entire system must be equal to 99.5%. Generally, there are three groups of components subject to failure in the interconnections: the compensation system (expansion bellows), the connections of the superconductors (splices) and the RF contacts. Assuming that the expected availability is apportioned to each family of components on an equal basis, and given the number of interconnections in the LHC, the expected reliability level for one interconnect (per system) is 99.9999%.

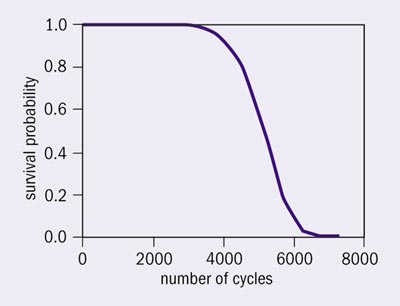

The LHC interconnections will consist of a total of around 250,000 components of different size and some 123,000 connections will be needed to integrate all these components. The main objective of the Quality Assurance Programme for the LHC interconnections is to minimize the risk of frequent failures of the critical components and to reduce the number of interventions. Figure 6 shows a typical plot indicating the measured reliability of one of the expansion bellows for the beam vacuum interconnects. Since the theoretically expected number of thermal cycles (including quenches) in the LHC lifetime does not exceed 50, the corresponding reliability of this component, i.e. the probability of survival, is very high and close to 100%.

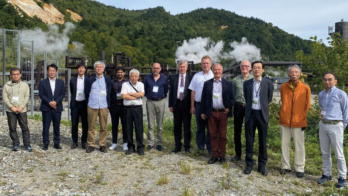

The interconnections are one of the few systems for the LHC that will be almost entirely assembled in the tunnel (under the supervision of the LHC Interconnections Section) and not in laboratory conditions. Therefore, to achieve the target availability for the interconnection zones, a strict quality-control procedure has to be applied during the assembly process. This function will be fulfilled by a team of physicists and engineers (see “The Polish connection” box), who will check the interconnections one by one before the final closure of the accelerator. This “debugging” of interconnection zones aims to eliminate the errors in the connections that might jeopardize the electrical, cryogenic or mechanical functions of the machine. Given the total of around 123,000 connections – and a typical error rate during the assembly of complex systems of 0.3%, the number of possible errors to be eliminated reaches some 370. This alone is a sufficient reason to focus a great deal of attention on the complex interconnection systems located between the LHC superconducting magnets.