On 26 December 2000 the Japanese KEK laboratory accomplished full powering of the superconducting solenoid magnet for the forthcoming giant ATLAS experiment at CERN’s LHC collider. On the initiative of Prof. Takahiko Kondo, this solenoid was designed and constructed under the leadership of Prof. Akira Yamamoto of KEK as Japan’s contribution to the ATLAS magnet system.

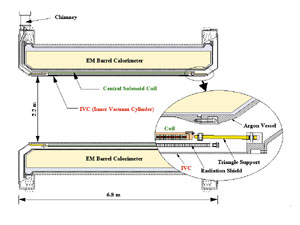

The large solenoid, which is 5.5 tonnes in weight, 2.5 m in diameter and 5.3 m in length, will provide an axial magnetic field of 2 T at the centre of the ATLAS tracking volume. As the solenoid coil precedes the barrel liquid argon (LAr) electromagnetic calorimeter, its thickness must be minimized to achieve maximal calorimeter performance.

Since the early 1980s, starting with the coil for the CDF experiment at Fermilab’s Tevatron, KEK has been steadily accumulating technical know-how on thin superconducting detector coils. Prof. Yamamoto and his team developed and constructed a full-diameter, quarter-length prototype of the superconducting solenoid for the proposed SDC experiment of the ill-fated US Superconducting Supercollider (SSC) project. This prototype was almost complete when the SSC project was cancelled late in 1993.

KEK nevertheless encouraged the team to carry out its test, which took place at the KEK PS experimental hall in early 1994. Precious technical data taken during this test essentially eliminated the necessity for major R&D on the ATLAS thin solenoid.

An idea to make the coil thinner, originally proposed by Prof. Yamamoto, is to use the superconductor not only as a current carrier but also as a main structural body to sustain the magnetic forces. He proposed a high-strength aluminium stabilizer for the superconductor. R&D on high-strength conductors began in the late 1980s at KEK and its usefulness was proven by the SDC prototype solenoid test. As the ATLAS solenoid shares the same conceptual design, it is not surprising that the ATLAS solenoid technical design report devoted a lot of attention to the experimental results of the SDC prototype.

The 12 km superconductor was developed and constructed by Furukawa Electric and Hitachi Cables. The conductor was coiled into 1151 turns inside an aluminium cylinder made by Oxford Instruments. The coil winding and curing, as well as subsequent assembly, were carried out by Toshiba in Yokohama.

Another distinctive design feature of the ATLAS solenoid is that the coil and the barrel LAr calorimeter share a single common cryostat and vacuum. This feature eliminates two vacuum walls. The coil is mounted inside the innermost vacuum cylinder (IVC) of the LAr cryostat using specially developed triangular glass-fibre supports.

The ATLAS barrel LAr cryostat, an in-kind US contribution designed by Brookhaven, is being constructed at Kawasaki Heavy Industry near Kobe in Japan. Early last year its vacuum vessel was completed and tested. Meanwhile KEK asked Toshiba to construct a “test IVC” for initial solenoid tests in Japan with a design similar to that of Brookhaven’s final IVC.

Thus in spring 2000 two nearly identical IVCs existed in Japan. KEK proposed to exchange these two before coil mounting. This would eliminate coil disassembly for the test IVC and remounting to the final IVC, which is planned to happen at CERN some time in 2003, when the full barrel LAr calorimeter is finally completed.

IVC exchange would not only save time and cost but also enhance quality assurance since all the delicate operations associated with coil mounting could be finished in the best working environment at Toshiba’s factory.

Although the argon vessel was still under fabrication, the Brookhaven team (led by J Sondericker) and Kawasaki agreed to accept KEK’s request for IVC exchange. However, on the administrative side this exchange of property was complicated by legal issues of ownership, as well as liability.

Finally the six interested parties – KEK, Brookhaven, CERN, ATLAS, Kawasaki and Toshiba – reached an agreement in early 2000, and soon the two IVCs were duly transferred between Yokohama and Kobe, a distance of about 500 km.

In the summer and autumn of 2000, Toshiba proceeded with the system assembly of the coil, radiation shields, triangle supports, helium pipes, power lines, control dewar and the test cryostat with the final inner vacuum vessel. Meanwhile the KEK cryogenic team completed the new liquid helium control system.

Early in December the assembly was completed and a KEK/Toshiba team began cooling and power tests at Toshiba’s works on the chilly shore of Yokohama Bay. Three observers from CERN followed the tests.

Initially the coil experienced two unexpected quenches, at 7.0 kA and at 7.6 kA. The voltage and temperature sensors indicated that both were caused by excess epoxy between the coil ends and the end flanges. No unexpected quenches were encountered during some 30 powerings. On 26 December the team achieved the maximum design current of 8.40 kA. This exceeded 7.6 kA, the operating point of 2 T, by 10% in current and by 20% in magnetic forces.

After a short New Year break the team continued further tests for emergencies such as power and cryogenics failures. The coil survived the worst possible case of full energy dump at 7.6 kA, and can be safely de-energized without quench following a sudden interruption of liquid helium supply. In addition tests verified that the coil is adequately and uniformly cooled, leaving at least two degrees of margin for superconducting operation.

At the February ATLAS collaboration meeting at CERN, the success of full performance tests was greeted by warm applause: the KEK solenoid team is now the front-runner in the long, tough race for ATLAS detector construction.

This autumn the solenoid and its associated cryogenics equipment will be shipped to CERN, where the solenoid and the barrel LAr calorimeter will be combined and fully tested.